Having soldiered on as the lone manufacturer in LMP1, following the departure of Audi and finally Porsche in 2017, Toyota was the first OEM to sign up to the new Balance of Performance-based (BoP) Hypercar rule package when it was announced in 2019. However, getting a head start was not necessarily the advantage it may first seem. As the machinations of rule makers flickered back and forth, early decisions taken on long lead parts could not be easily altered to better suit new rules, and it wasn’t able to fully exploit the finished regulation package.

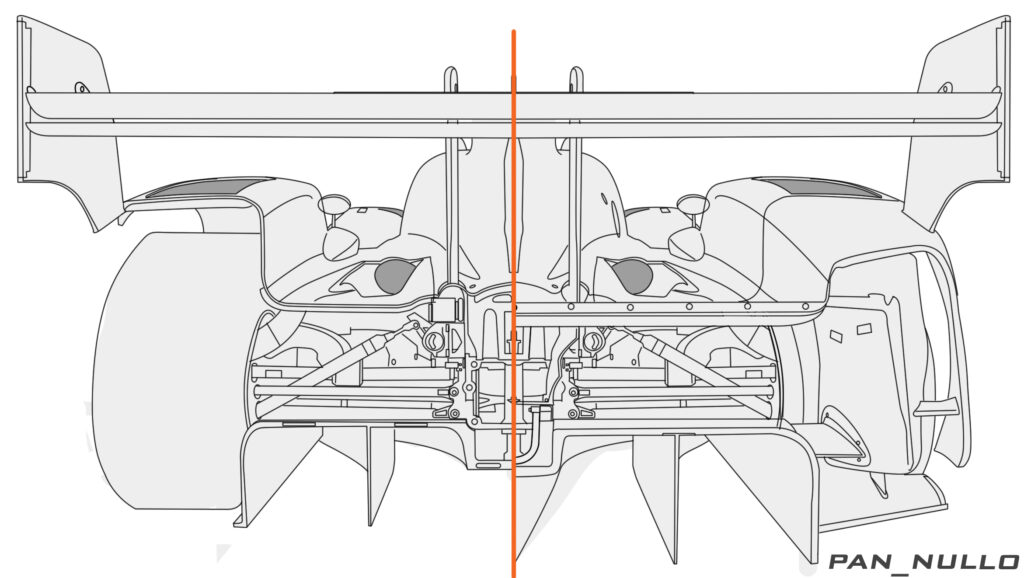

Following the TS family of LMP1’s almost decade of development, Toyota evidently wanted to maintain the lineage, and at first glance the family similarity between the previous model and the GR010 is clear. The basic architecture of the car carries much over from its forebear: a mid-mounted, 520kW (698bhp), 3.5-liter twin-turbocharged V6 – in 2021 Le Mans trim – sits behind the driver, while a 200kW (268bhp) hybrid motor equips the front axle. The Hypercar rules permit only a single MGU rather than the two allowed in LMP1, and total power output is capped at 520kW. The demands of the rules have subtly altered the car’s proportions compared with the TS line. For example, the tub is longer due to a stipulation that the battery must now be housed behind the driver (the TS050’s was placed in the passenger compartment), and notably the overall vehicle weight is also some 162kg heavier, at 1,040kg.

Chopping and changing

John Litjens, project leader for Hypercar at Toyota Gazoo Racing (TGR), explains that one of the greatest challenges faced while developing the car was adapting to the evolving rule set. “The biggest impact was from the relatively late minimum weight changes,” says Litjens, as initially, the minimum weight for LMH was set at 1,100kg. “When you have a high minimum weight, you want to spend weight for reliability, much more than we did with the LMP1. You design the car to take some ballast, but when you suddenly have the weight reduced by 60kg, that ballast you planned is all gone.” It might be assumed that as TGR was able to build an LMP1 car with two hybrid systems and a large battery down to a weight of 875kg, finding last-minute savings in the LMH would be straightforward.

However, as Litjens points out, the rules set minimum weights for parts such as the tub, engine, gearbox and other systems. “I think if we had known from the start it would be 1,040kg for the hybrid cars, it would have been relatively easy. For example, with the engine, if you think it can be a bit more reliable by going a little over the minimum weight, you take advantage of that because you have the overall weight to spend. If that weight is suddenly not available, but the designs are kicked off on a long lead time item, it is too late to change.” The same consideration applied to providing leeway to ballast the car’s weight distribution, ensuring it could work with what was still an under-development tire from Michelin. “If you have 50-60kg to play with, you can do quite a lot,” muses Litjens. “If you have nothing, then you are stuffed.”

Certain regulation requirements have also contributed to the extra mass, beyond the stipulated minimums. For example, the longer monocoque and battery positioning meant the GR010 inherently incorporates more material than the LMP1 version. Toyota also took advantage of the increased overall weight to make the tub more resilient. “For example, with the suspension mounting points, where in the past we had a certain safety factor built in, we have increased that,” says Litjens. The desire for extra robustness was not solely related to track conditions, but also to the changing nature of the racing Toyota expected to encounter. “With the BoP you will have tighter fights [than in LMP1] and there might be more chance for contact, and you want to be prepared for that,” he suggests. Given the evidence on the first lap of this year’s 24-hour race, where the #8 Toyota took a solid hit to the rear from the #708 Glickenhaus, and survived, this approach was vindicated. Another significant difference between the Hypercar and old LMP1 is the suspension design, with the regulations now outlawing the use of tools such as inerters and interlinked suspension systems – both of which featured on the TS050. “It really is back to basics,” says Litjens.

Despite having fewer tools in the box to control the chassis, and with it the aero platform, Litjens points out that greater allowances in other areas of the rules mean this is far from an insurmountable problem. Specifically, greater aerodynamic freedom has reduced the need to compromise the suspension geometry to accommodate aero performance features. “Of course, you still want to keep the platform as stable as possible, but you do have a bit more freedom to play with the kinematics of the suspension. If a suspension leg ends up disturbing the aero a bit, you have freedom to compensate for it in other areas to stay in the FIA [performance] window,” outlines Litjens.

Aero freedom

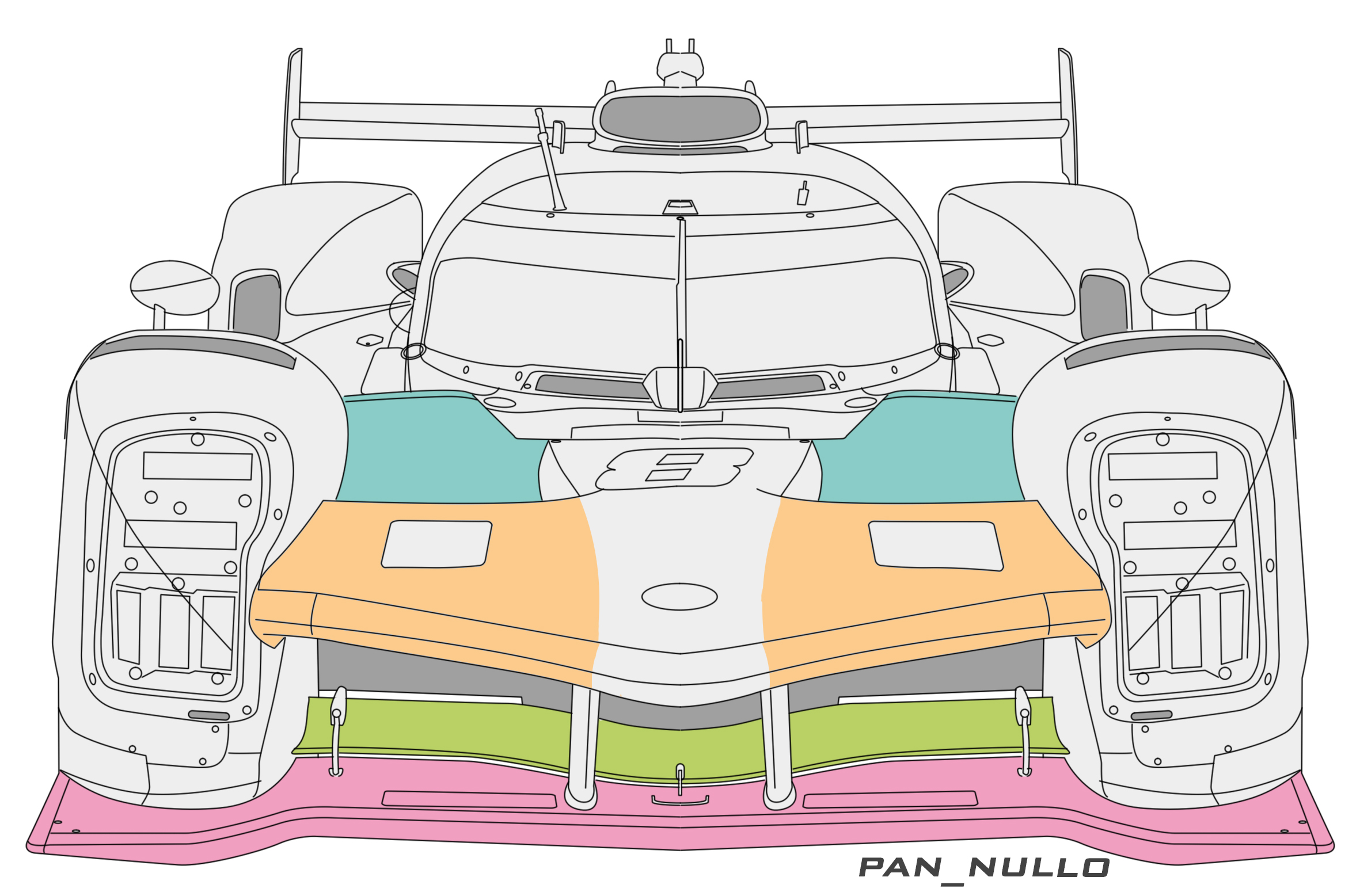

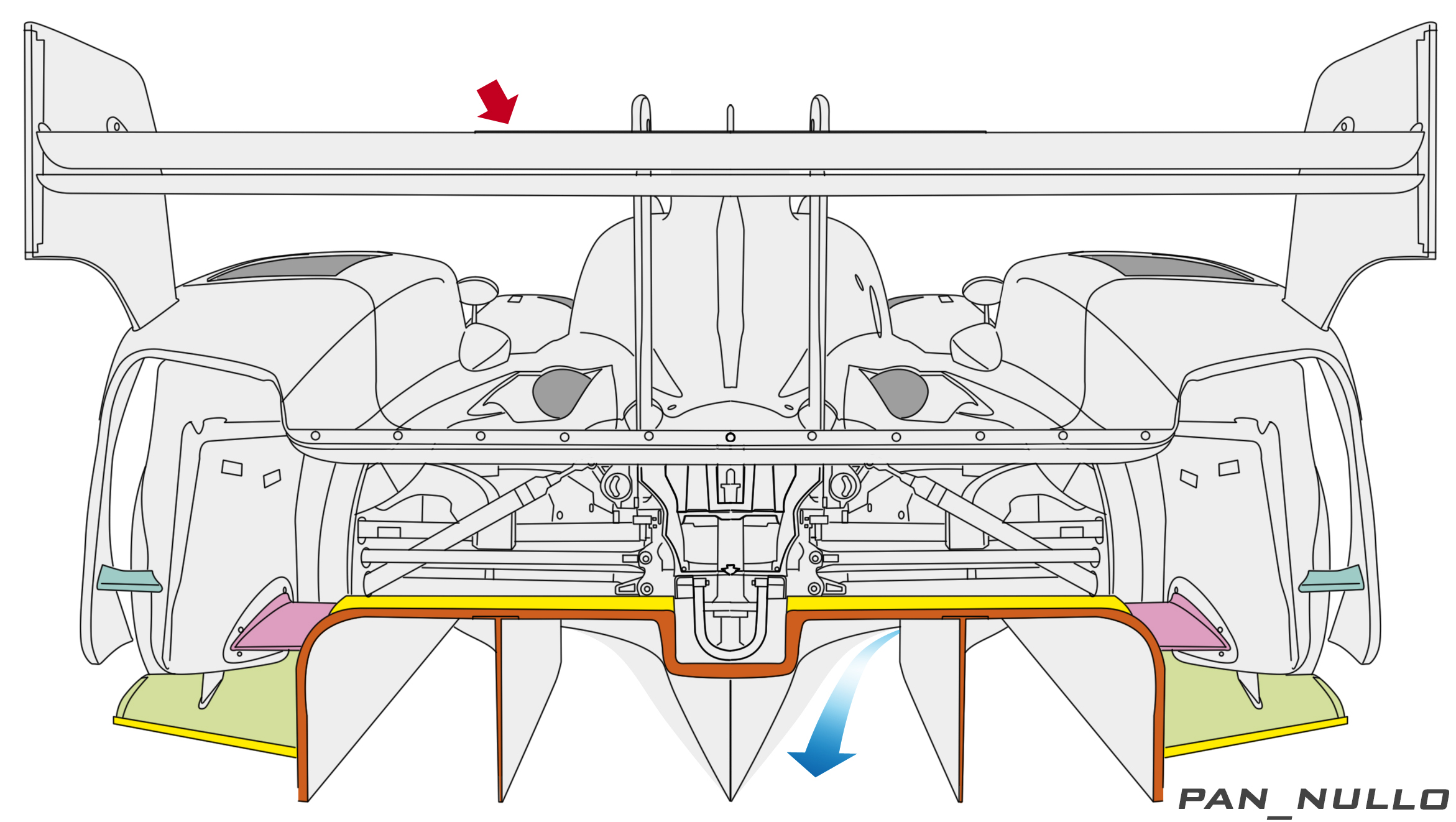

Hypercars are limited to a single bodywork specification across the season, including Le Mans, where previously teams would run a specific low-drag aero kit. As a result Toyota’s aerodynamicists have had to make compromises that were not required in the past, to ensure the package worked across as wide a range of conditions as possible. Describing its approach to the aero, Litjens says, “You stick with a base that you know, especially as we are only allowed one adjustable device, and still have to go to different circuits, from Le Mans to Portimão.” When asked whether Toyota ever thought about going for a wingless design similar to that shown off by Peugeot on its 9X8, Litjens notes that the approach was never discussed. “We felt it [a rear wing] was the easiest route to take and didn’t even think about getting rid of it.”

For the BoP process, the GR010 had to be tested by the FIA at Sauber’s wind tunnel in Hinwil, Switzerland. Toyota did the majority of its aero development in the TMG (Toyota Motorsport Group) tunnels using a scale model, with final validation at full scale. However, the use of a different tunnel for BoP had the potential to cause issues if Toyota’s own results diverged from those of the FIA. “Luckily, we were not too far out, because you only have one day [for the FIA sign-off]. If you turn up and are completely outside the window, you will struggle. We made sure we had some options available to tune things if we needed and were okay,” says Litjens. The regulations set an aerodynamic efficiency target of around 1:4 L/D, although this was upped slightly in a late revision to the rules. To assess each Hypercar design, they are run at Sauber across a wide range of ride heights, airspeeds and yaw angles to create a comprehensive aero map. Once a car is passed, the FIA conducts a 3D scan of the bodywork to create a reference set of CAD data. At any point in the season, the FIA can seize a car and rescan it to check it remains in compliance with its original homologation.

Powertrain simplification

Toyota has retained the same 3.5-liter, twin-turbocharged V6 engine layout it used in the TS050 for the GR010, but, says Litjens, it is an all-new design, which more closely represents the company’s road car offerings. Without the need to hit stringent fuel usage targets, there was less pressure to focus on outright efficiency. Similarly, the inclusion of a minimum engine weight of 165kg and CoG of 220mm lowered the emphasis on reducing the mass of every part. Initially, the Hypercar regulations also defined minimum weights for the hybrid system, and as such, Toyota worked to these. It also kept a close eye on costs, with Litjens stating that the battery technology, for example, is now much more closely related to that found in the road cars.

However, in one of many regulatory about-faces, the minimum weight requirement for the hybrid was removed – the only limitations being a maximum RPM of 25,000 and a minimum laminate thickness of 0.1mm – but Toyota was already committed to the weight-constrained design and could not further optimize its solution. On the TS050, Toyota worked with separate suppliers on its hybrid motors, Aisin providing the front unit and Denso the rear.

In an interesting move, the new car’s hybrid (by regulation it only has a front motor) is now a collaborative effort between the two companies. The management of the hybrid system’s contribution to the total vehicle power needs handling in a different way to that of the previous LMP1 class. In Hypercar, the total output (IC engine and MGU) is fixed at 520kW. It was initially due to be only 500kW for Le Mans, but this was revised following the opening races of 2021 in order to increase the gap to the LMP2 class.

As to whether or not the energy management knowledge gained in LMP1 was relevant to the new hybrids, Litjens says, “It’s 50:50. Energy management, state of charge of the battery and how it reacts under load are the same. But what is different is that before, you had your combustion power and then, when you needed more, the hybrid on top, which made it easier for the drivers to overtake. “Now, you have the maximum power and it doesn’t matter whether you are taking 400kW from the engine and 120kW from the hybrid, or any other combination of inputs, so the controls there are quite different [compared with the LMP1 hybrids].”

That’s not to say that deployment strategy becomes irrelevant. Litjens points out that the contribution of the hybrid motor provides an instant torque addition, which is particularly beneficial on corner exit. He also highlights that the IC element of the powertrain must always be capable of producing the maximum output “in case you end up in a situation where you have run out of hybrid power”.

The upshot of the new rules is that the upper bound on power output must be tightly respected, as must the homologated power curve. With torque sensors mandated on all driven axles, the FIA is able to monitor performance in real time and the tolerance provided is narrow. Incidents such as skipping over a harsh curb could easily cause an unforeseen torque spike, placing the team in line for a penalty. “In the past it was not really an issue, except for reliability. But now, for sure, you need to be very careful, and have to spend some effort on those controls,” says Litjens.

Of course, racing being what it is, the margins are there to be pushed and he readily admits that any safety margin needs to be as small as possible to be competitive. Development hurdles The first GR010 prototype ran on its maiden test in October 2020. Toyota’s target for any new car pre-Le Mans is to complete at least four 32- to 36-hour endurance tests. Covid-related travel restrictions made achieving this tricky, compounded by snowfall at a session in Portimão, necessitating scheduling an extra test.

Conscious that its Le Mans ambitions had been scuppered in the past by issues that could have been worked around (such as its ECU failsafe shutting down the motor on Nakajima’s car in 2016 when it could have run back to the pits), Litjens notes, “It is not just pure development testing, but also working on the ‘what ifs’. We have learned over the years to focus on reliability but also have systems ready to react if something fails.”

So how does a team win in a BoP class? In Litjens’ opinion, a competitive advantage is found in being able to hit the upper end of the performance window across all conditions. “You have to be consistent – the car, the drivers, in all conditions. You can have a car that is perfect aerodynamically in free air, but if you end up in traffic, you also need to be as stable as possible.” This consistency is achieved in many ways that go beyond the pure mechanical design of the car. For example, he points out that if particular surfaces prove to be susceptible to debris pickup over the course of a race, this can damage aero performance and must be mitigated.

Toyota clearly had good pace at Le Mans, easily able to put in quicker lap times than its competition when needed. Although the 1-2 result in the race may not suggest it, all was not plain sailing for Toyota, with the second-place #8 car having a torrid time. Most significant among the dramas was a fuel pickup issue, which technical director Pascal Vasselon said was the same as one experienced at the pre-Le Mans Monza WEC round. That previous occurrence had necessitated a 45-minute pit stop to change a fuel collector, but at Le Mans, the team’s aforementioned ‘what if’ preparations paid off and it was able to devise a workaround. Toyota clearly had pace to spare; its 3 min 23.9 qualifying lap at Le Mans placed it well clear of the competition. However, with the arrival of Peugeot and Ferrari in Hypercar and a pack of manufacturer-backed LMDh (Le Mans Daytona h), BoP or not, it may need all that speed and more as sportscar racing enters its new golden era.