The Le Mans 24 Hours race is a high endurance, day-long slog that puts the world’s best race cars to the test. In 2017, jaws dropped when an LMP2 car was placed second, and third overall. But why was this a poignant moment for this engine type and why is this significant to the design and development of these race car engines? And how does miniature bearing specialist SMB Bearings fit in?

A Le Mans Prototype (LMP) is the type of sports prototype race car used in the Le Mans 24 Hours, FIA World Endurance Championship (WEC), IMSA WeatherTech SportsCar Championship, European Le Mans Series (ELMS) and Asian Le Mans Series. For a car to be compliant for entry in either the LMP1 or LMP2 category, certain design criteria must be met.

In a previously LMP1 dominated race, the 2017 Le Mans 24 Hours saw two LMP2s on the overall podium. For a race that had never previously seen an LMP2 car lead, let alone take an overall podium place, it does pose the question, what has changed?

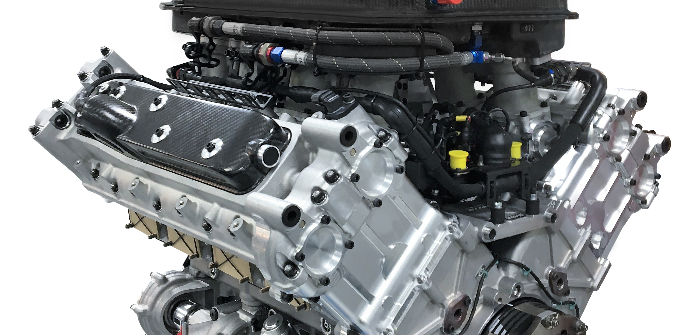

High-performance powertrain manufacturer Gibson Technology was chosen by the FIA/ACO as the sole engine supplier for LMP2 class sports cars from 2017 to 2020. All race cars in the LMP2 category during this period are equipped with the latest development from Gibson, the GK428 engine.

The GK428 is the current spec engine supplied to all LMP2 teams competing in the WEC, the Le Mans 24 Hours, ELMS, IMSA Weathertech Championship and the Asian Le Mans Series (from 2019 onward). It has been specifically developed for endurance racing and is one of Gibson’s most technically advanced engines, incorporating the latest design, manufacturing and development techniques.

When the GK428 made its debut at the 2017 Le Mans, there was a lot at stake. A record 25 cars were powered by Gibson engines, with the company supplying and supporting 19 different teams. The results spoke for themselves, with 12 LMP2 cars placed in the overall top 16. Twenty-one of the 25 Gibson-powered LMP2s finished the race, with the four retirements unrelated to engine issues. It really was the year of the LMP2 – even if the LMP1 Porsche did take the lead in the penultimate hour of an incident-filled race.

A decade ago the engineering department at Gibson was faced with a major challenge –sourcing thin section bearings for throttle barrels capable of functioning in the hostile environment of a race engine. The company approached SMB, which supplied EZO thin section ball bearings, suited to applications when weight reduction is required and where space is at a premium, as with the case of the throttle barrel.

“The success of these bearings in Gibson’s engines has been a huge testament to the skilled manufacturing that goes into EZO’s bearings,” said Chris Johnson, managing director of SMB Bearings. “The endurance, as demonstrated out on the Le Mans track, has been amazing to watch.”

“This unique bearing design isn’t readily available, so we are pleased to have SMB on hand to ensure there is always a good supply available,” said John Manchester, operations director at Gibson Technology.

When it came to testing and validating the race car engines, with SMB’s bearings installed, the entire engine was evaluated on a testbed, enduring the equivalent cycles of two races of Le Mans (48 hours). After this test, all parts were stripped and analyzed. Satisfied with the performance of these bearings, SMB’s bearings have now been used in the assembly of every single Gibson Technology engine for the last 10 years.