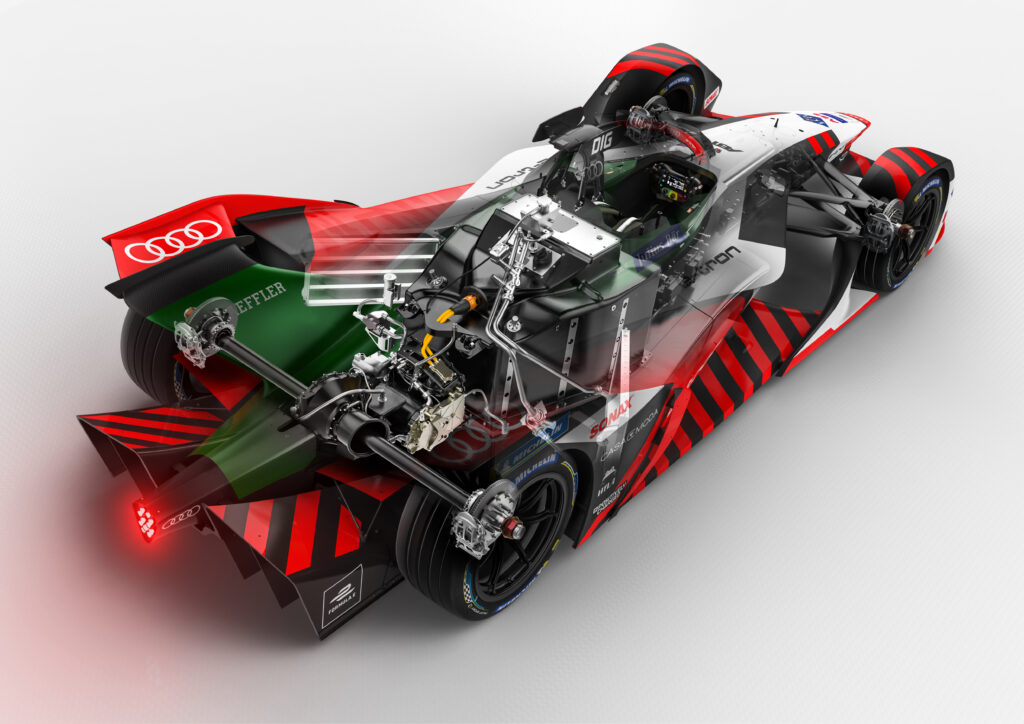

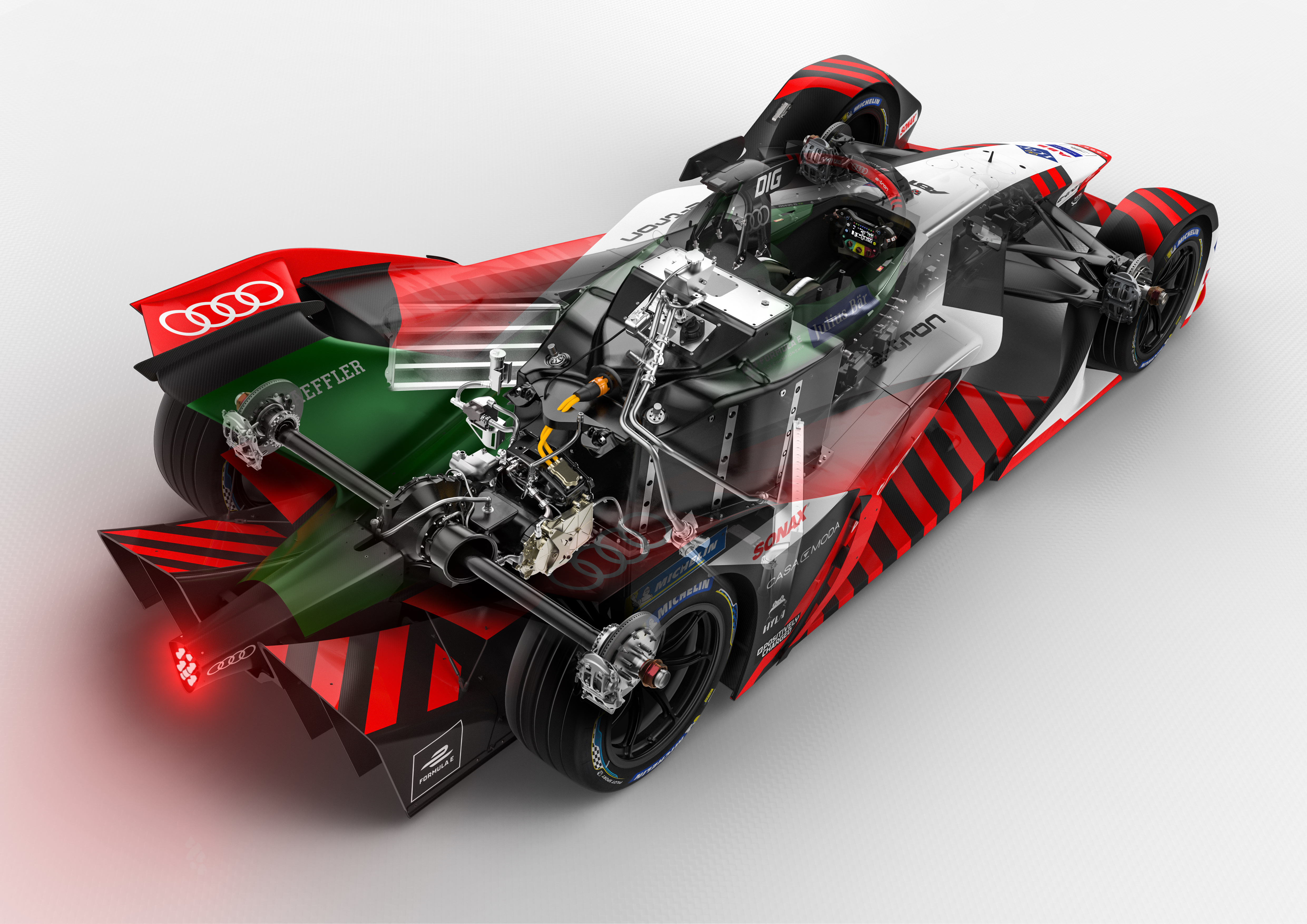

Previously the preserve of Formula 1 and the WEC, as cost decreases and desire for electrification increases, motorsport-specific electric and hybrid systems are now appearing in multiple categories. Suppliers can provide competitors with either bespoke or off-the-shelf designs; however, series are predominantly opting to instead mandate standardized systems in the name of cost control. Regardless of whether a spec or custom system is used, all feature three key components – traction motors, inverters and a battery system – the first two of which will be looked at in greater detail here.

Speedy switching

An inverter is an electrical device that converts electricity from a DC source such as a battery into AC, to drive a traction motor. The DC power is fed to the primary winding of a transformer in the inverter and using an electronic switch – which in the case of a modern hybrid powertrain will be a series of power semiconductors, generally either insulated gate bipolar transistors (IGBTs) or metal oxide semiconductor field effect transistors (MOSFETs). The electrical charge travels into the transformer’s primary winding, then abruptly reverses and flows back out, with this in-out flow producing an alternating current within the transformer’s secondary winding. The induced current flows to, and produces power from, the electric motor.

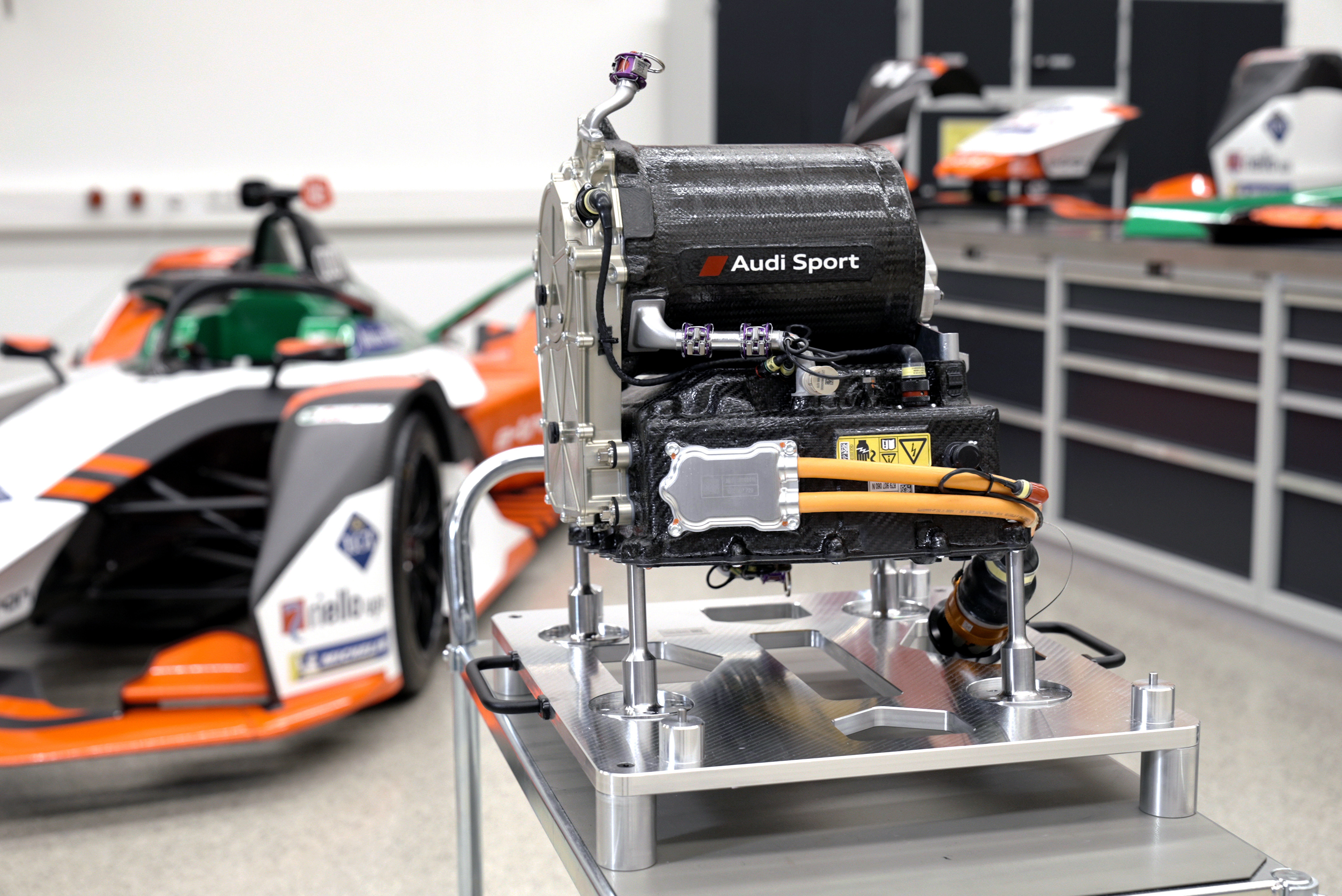

Governing the torque delivery of the motor is a matter of precisely controlling the switching of the energy flow, which in the case of most high-performance motors, needs to happen at a very high frequency. The process is reversed if energy recuperation under braking or throttle lift is implemented. For motorsport use, efficiency is king, both in terms of motor and inverter operation. As motor speeds increase (most Formula E powertrains, for example, now operate in excess of 30,000rpm) there is a need for high-speed switching capabilities, up to 75kHz, in order to maximize motor efficiency, while the thermal efficiency and losses of the inverter itself also need to be considered. Reducing heat rejection from the inverter not only benefits electrical efficiency, but also reduces the need for cooling provision, which in turn can be harnessed to reduce vehicle drag.

In order to meet these demands, inverter manufacturers have turned to silicon carbide (SiC) power semiconductors, and there is also growing interest in gallium nitride-based (GaN) units. Both are wide-bandgap (WBG) materials, which references the energy difference in semiconductors found between the top of their valence band and the bottom of the conduction band. Having a WBG enables such devices to operate at higher voltages, temperatures and frequencies than traditional narrow-bandgap materials.

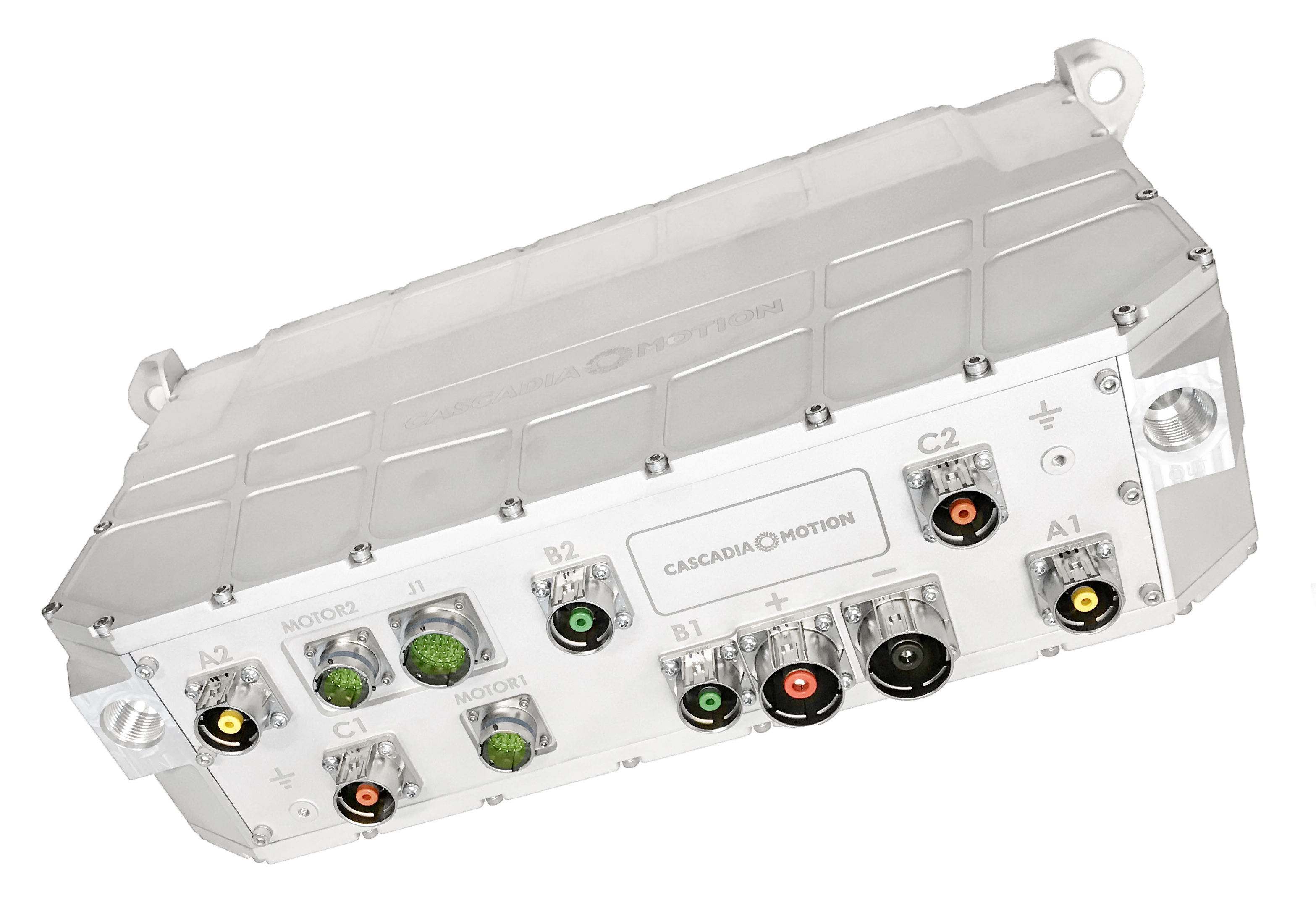

Cascadia motion inverter

Ten years ago, the only real solution for a high-power inverter was silicon-based IGBT; however, as power levels and operating speeds have increased, the switching speed and temperature constraints of Si devices have seen them supplanted by SiC-based options. Initially, this was in the form of hybrid Si IGBTs, which also incorporated SiC components. For example, in season three of the Formula E championship, supplier Rohm, working in conjunction with the Venturi team, used a hybrid inverter design that paired an Si-based IGBT with SiC Schottky barrier diodes. The result was an inverter some 2kg lighter and nearly 30% smaller than the team’s season two system. However, with improvements in SiC-based MOSFETs, previously limited by their relatively low voltage tolerance, pure SiC devices are now more readily available and proving popular thanks to their greater speed potential and smaller volume.

In the case of the aforementioned Venturi team, a switch to an SiC MOSFET-based system in 2017 netted a further 4kg weight saving and 30% size reduction, with a drop in switching losses of 75% compared with a conventional IGBT solution. Regardless of the inherent benefits provided by SiC-based devices, peak operation depends on their being packaged for best performance. One notable advantage of SiC over silicon is its greater thermal conductivity, and the proper cooling of components is vital to achieve maximum efficiency.

For example, Marelli, working in conjunction with the German Fraunhofer Institute for Reliability and Microintegration, recently released details of an SiC-based inverter that features a structural design devoid of a base plate, reducing thermal resistance between the SiC components and coolant. The result is a claimed energy conversion efficiency of up to 99.5% coupled with a 50% reduction in both size and weight when compared with a conventionally cooled inverter.

GaN is only just starting to gain prominence as a suitable semiconductor material for power electronics. GaN is a WBG material, so it is capable of very high switching speeds and has a high breakdown voltage. It also has around 50% lower losses (thanks to minimal reverse recovery charge) than SiC, making it an attractive option for high-performance motor drives. Currently, mainstream applications of GaN are limited to DC-DC converters, rather than traction motor drives. In this role, GaN-based converters are in widespread use in series such as Formula E, and the ETCR series uses GaN DC-DC converters supplied by French specialist BrightLoop. However, some manufacturers are actively investigating the use of devices such as GaN HEMTs (high electron mobility transistors) and FETs (field-effect transistors) for motor inverters. Marelli recently formed a partnership with GaN semiconductor developer Transphorm, and others such as Ricardo and ZF have struck similar agreements. Until recently, there were reliability concerns around GaN-based transistors, but these would seem to have now been overcome and adoption of GaN is likely to become more widespread in the near future.

GaN is only just starting to gain prominence as a suitable semiconductor material for power electronics. GaN is a WBG material, so it is capable of very high switching speeds and has a high breakdown voltage. It also has around 50% lower losses (thanks to minimal reverse recovery charge) than SiC, making it an attractive option for high-performance motor drives. Currently, mainstream applications of GaN are limited to DC-DC converters, rather than traction motor drives. In this role, GaN-based converters are in widespread use in series such as Formula E, and the ETCR series uses GaN DC-DC converters supplied by French specialist BrightLoop. However, some manufacturers are actively investigating the use of devices such as GaN HEMTs (high electron mobility transistors) and FETs (field-effect transistors) for motor inverters. Marelli recently formed a partnership with GaN semiconductor developer Transphorm, and others such as Ricardo and ZF have struck similar agreements. Until recently, there were reliability concerns around GaN-based transistors, but these would seem to have now been overcome and adoption of GaN is likely to become more widespread in the near future.