Simulation software specialist rFpro is now working with multiple Formula E teams; scanning the tracks overnight, after they have been erected, throughout the season to ensure teams receive the most up to date and accurate data for their simulations

UK specialist software company, rFpro, is supplying simulator software to top Formula E teams to improve the accuracy of their battery energy use predictions. Already dominant in the simulator market for Formula1, WEC and NASCAR, rFpro now has three Formula E customers.

“Success in Formula E requires a team to squeeze all the available energy from the battery pack by the time the car crosses the finishing line, otherwise the driver could have gone faster at some point in the race,” said rFpro’s technical director, Chris Hoyle. “Optimising the energy consumption by adjusting the calibration before the race relies on having an accurate circuit model, but with many circuits based in parks or city centres, the exact radius of the various corners may not be known until the barriers and kerbs have been laid.”

rFpro has overcome this challenge by offering an overnight service re-scanning the entire circuit after it has been constructed for the race weekend and updating the circuit model data. Though simulations are already used in Formula E, their accuracy is often compromised by the quality of the input data.

“Some teams rely on information sources such as Google Earth, which is really not accurate enough to give the precision required for optimising energy use,” added Hoyle.

Simulation using a Driver-in-the-Loop (DIL) overcomes another problem faced by teams trying to optimise performance; the shortest, theoretically quickest, line around every corner is not always taken by the drivers because public-road circuits include bumps, repairs, pot holes and drain covers that could cause loss of control or reduced grip. Predicting the best line for a driver to take requires accurate ride and handling simulation, something which was not possible with older simulators because their response time was too slow and their circuit data was inadequate.

“To ensure that a driver behaves exactly the same in the simulator as on the track, the experience must be totally convincing; this means all the cues – visual, aural, haptic – must arrive without perceived delay in real time,” said Hoyle. “Some of the older simulators had up to a quarter of a second delay, called latency, which meant they were limited in their capabilities. Our software provides video signals 10 times faster, and audio signals 20 times faster, with every pixel on the video screens in exactly the right place, optically correct to a fraction of a degree.”

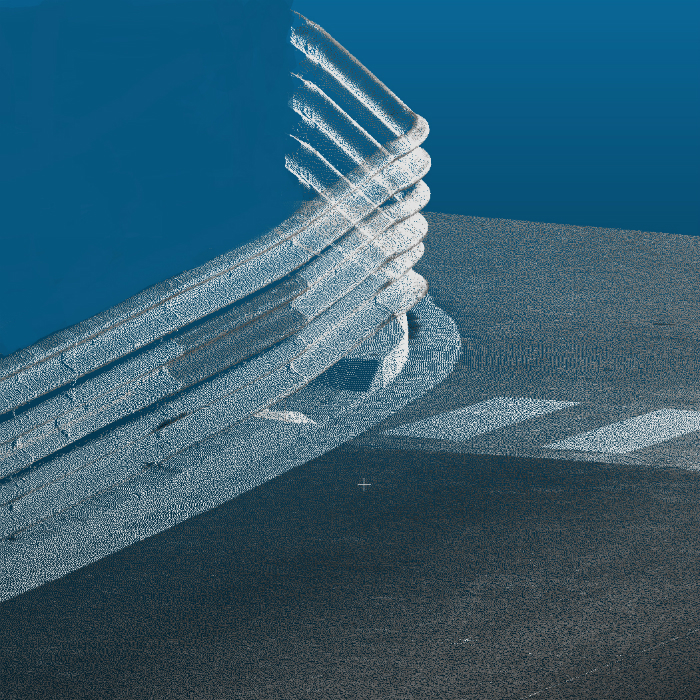

The other key element in providing complete immersion (realism) in the simulator is an accurate road surface model for the effective simulation of response to road inputs, such as ride and impact harshness. rFpro’s simulation software, TerrainServer, accurately reproduces every bump, kerb, ripple and camber from the actual track, feeding high bandwidth, high fidelity, cleaned LiDAR point cloud data for each tyre contact patch into a vehicle model in real time at up to 4kHz.

“If the proposed 2018/ 19 Formula E rule changes go ahead, we will see the end of drivers switching to a second car during the race,” said Hoyle. “Having only one car, with one battery pack as an energy source, will place even more emphasis on extracting the maximum available energy; something which accurate simulation can help to achieve.”

Submitted by: rFpro