Paolo Ponzo is a senior structural engineer with Italian motorsport and automotive composite specialists YCOM. In a recent interview released by the company, he highlighted some of the challenges of modern composites development and outlined his path into the complex world of composites simulation.

How did you end up as a composites engineer?

By the age of 4, I was already traveling from Sanremo (Liguria) to Parma to race with go-karts. Later, my passion for racing cars led me seamlessly to a degree in mechanical engineering for the simple reason that I wanted to build cars.

During my studies, I took part in the Formula Student and, during the master course, I got passionate about the composites field. My first job experience was in Automobili Lamborghini, where I was in charge of structural simulation and carbon composite components. I worked on different vehicle parts – bodywork, interiors, suspension components – up to the complete body in white.

What were your key areas of responsibility during your time at Lamborghini

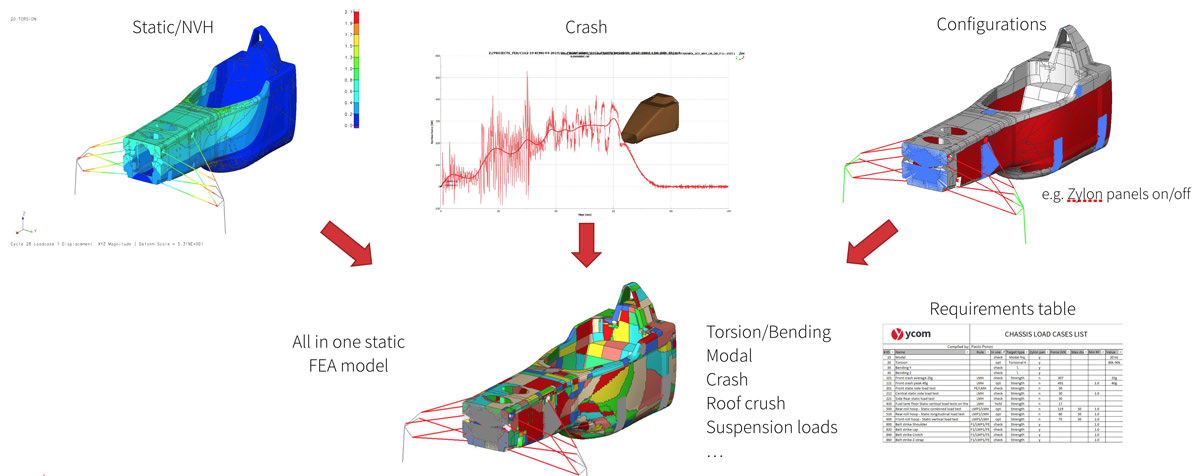

I was taking care of the whole composite Body In White (BIW) sizing, considering both static (NVH) and crash requirements. Dimensioning an automotive BIW requires the study of two different disciplines (NVH and Crash) that are normally studied separately because the simulation models and the involved equations are different.

The main challenge was putting all the requirements together considering both disciplines, to be able to make the chassis comply with all the targets and be as light as possible. This is the way to make a light and safe structure. It has been an extremely challenging experience.

What is your current role?

In 2020 I joined YCOM as a senior structural engineer and continue my path on simulation and composites. I now lead a growing group that is fully dedicated to simulation and focused on composites.

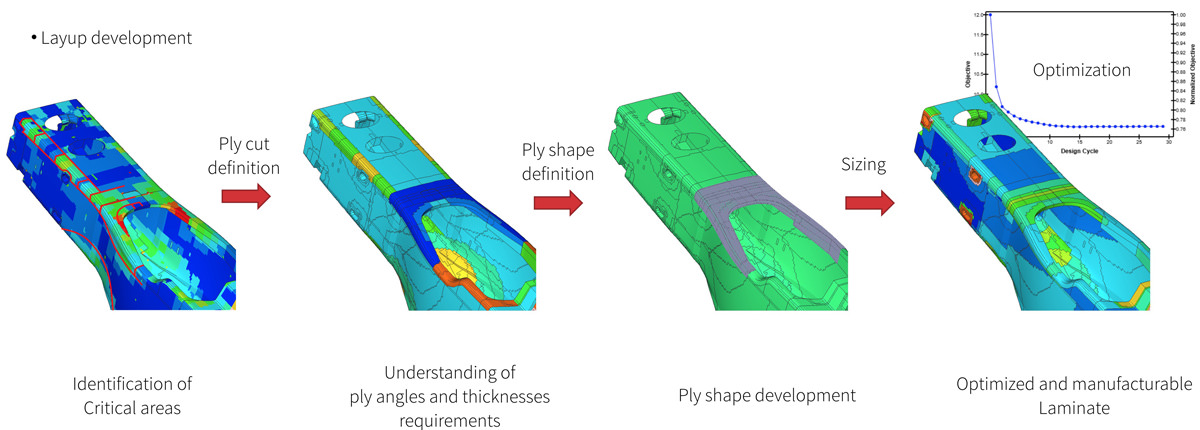

Every day we are involved in supporting designers in producing strong and light parts. We start from defining components requirements and proceed to preparing the simulation models. These models are used for developing the composite layup and for structural verification.

Our working methods are completely based on numerical optimization; we make use of tools that help us understand optimal distribution material and fiber direction. This way we can guarantee the structure to be as light as possible and able to withstand the loads.

We are also involved in material and components testing, since we need to compare our simulations with real life tests.

What is the most complex aspect of composite monocoque simulation?

What is the most complex aspect of composite monocoque simulation?

The most complicated aspect of simulation is when we need to understand how materials damage, like in a crash analysis for example. In this case, knowing the material characteristics under normal circumstances is not enough, we need to know also how the material behaves after it fails! One of the critical aspects of the crashworthiness of a structure is the development of the energy absorbers.

Indeed, such components govern the event dynamics and generate the loads on the structure. When aluminum is used, the simulation can predict real behavior; when we use composite structures instead, the simulation is not predictable, so testing activities, combined with know-how and experience, must support it. The development of such components must be done correctly since it directly impacts the safety of the driver.

What is the next goal for your team?

Today the challenge is to bring the complexity of automotive together with the tailoring of motorsport into other engineering fields to create unique products! We still need to develop tools and methodologies to automate the processes further, but we are on the right track.