GT3 is an unrivalled success with myriad global series running to the rule set and, from next year, eligibility at Le Mans and in the WEC for the LMGT3 class, replacing GTE. Since the category was introduced in 2005 the cars have changed beyond recognition, from relatively close representations of production machines to the current bespoke creations. Despite only the slimmest of connection to its road car counterparts, GT3 is still a cheaper proposition than the outgoing GTE class, and competition is fierce between manufacturers looking for trade.

It is against this backdrop that Ford has unveiled its latest customer racer, the Mustang GT3, coordinated with an extensive revamp of the production model. Ford was bullish about the new arrival when it was presented at Le Mans, and with good reason, as it simultaneously announced a significant scalp: long-time Porsche customer WEC GTE team Proton Competition will switch to the Blue Oval for 2024.

PMW speaks to Larry Holt, founder of Multimatic, which was tasked with the thoroughbred’s development and production, to find out what it takes to build a car for the new age of GT3.

Strong roots

Multimatic has laudable history in sportscar racing, with prototypes as a chassis supplier for LMDh and LMP2, and GT cars. It took the spotlight back in 2016 with the Ford GT, which raised the bar for GTE. That was a pure works effort, and Holt is at pains to point out that the Mustang is different: “This time, the real focus for us and for Ford performance is customer racing.”

Multimatic and Ford began work on the GT3 in 2021 with the first concepts based on the new road car, but the project was kept under wraps until early 2023. The latest iteration of the GT3 rules are much more liberal than in the past, with manufacturers permitted to do away with almost all of the production car structure, excluding the central chassis area.

Multimatic took full advantage of this freedom, and under the muscle car body are separate front and rear subframe structures carrying the engine and suspension members.

Double wishbones are used all round, replacing the standard MacPherson strut setup (which features a dual-length lower wishbone to provide a virtual turn center on the production car). “To use double wishbones, we had to add in some structure so the subframe carries all of the suspension pickup points on it,” outlines Holt. “That means we could do really anything we wanted with the geometry, which front and rear is completely unique to this race car.”

Of course, Multimatic’s DSSV dampers feature all around, providing five-way adjustment and plenty of scope for fine-tuning (or getting hopelessly lost, depending on competence). The DSSV system replaces the traditional shims found in a damper with spool valves (spring-loaded cylindrical sleeves), which Multimatic says provides greater control and consistency of damping force.

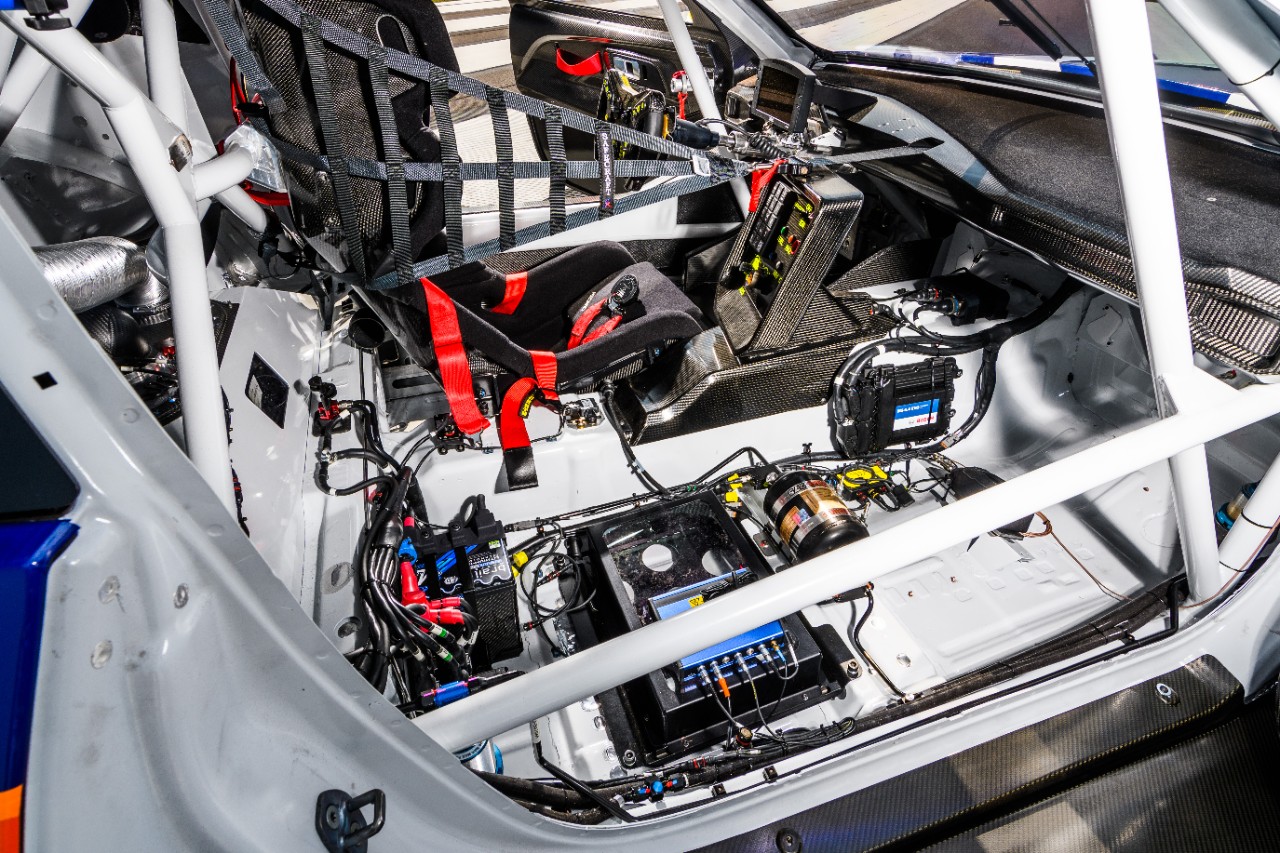

The core Mustang chassis is reinforced with a 14CDV6 steel cage tied into the body-in-white structure. “From the firewall back to behind the seat, that’s all Mustang. And then everything else is subframe,” notes Holt. Said subframes are affixed using joints secured with clevis pins rather than studs and nuts. This design feature, says Holt, was driven by experience of studs pulling out from the central chassis on a previous GT car, negating some of the maintenance benefits of running replaceable subframes.

He points out that features such as this should mean the overall cost of ownership for teams is lower than for previous GT3 machines, despite the initial purchase cost being greater. “I mean, it doesn’t take much of a hit to toss one of the [older GT3] chassis in the garbage. Okay, this chassis is probably 25 grand more, but that is if you bought the whole chassis. You’re never going to have to change the center section, that should never have to be replaced.”

The concept also means repair times are much shorter. “If you backed it into a wall, you could probably put it out in the next session with competent mechanics, though the front is a bit more difficult because of the cooling.”

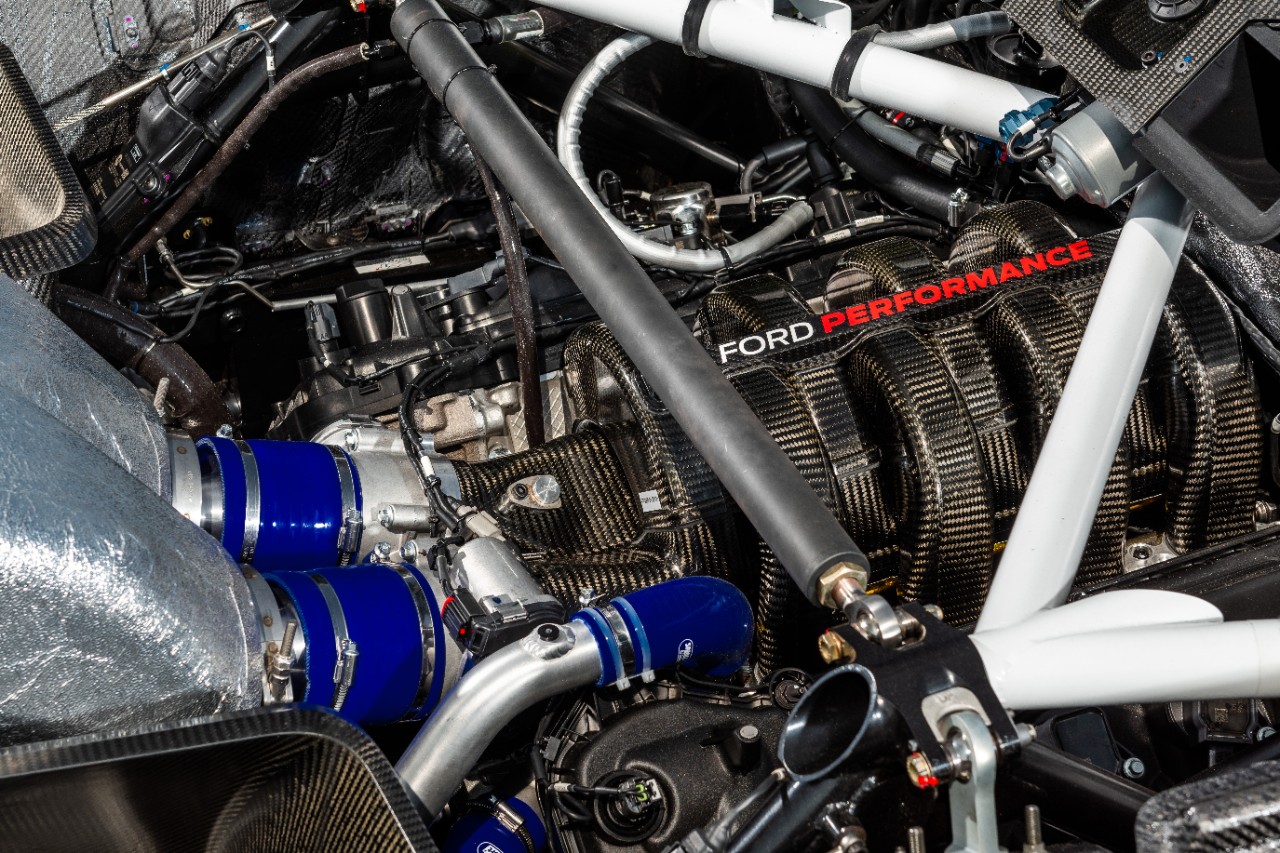

Under the hood, Ford’s latest-generation Coyote V8 is used as the basis for the GT3 engine, with capacity increased from 5.0 liters to 5.4. However, rather than being built by Ford Performance in Dearborn, Michigan, development of the engine has been undertaken by M-Sport in the UK, which will build and maintain the units. The transmission is from Xtrac, mounted in a transaxle configuration at the rear, with power fed via a carbon propshaft. It is closely related to the unit found in the latest Mk4 Ford GT (an extreme, track-only special) but with a revised snout to suit the installation.

Aero development

With BoP (balance of performance) the prime limitation on aero performance in GT3, Multimatic’s job was to ensure the Mustang fitted in the required window across as broad a range of conditions as possible while also remaining driveable. “That’s what we have to do these days. We have to make these cars fit into the limits that we’re allowed to fit in. And this does, but we’ve done it in a way that’s totally benign. The downforce is independent of the pitch and roll that the car sees, and that makes it much easier to drive,” says Holt.

The development program required to achieve this was extensive. Holt estimates that more than 1,000 CFD runs were conducted, in addition to around 20 days running at 40% scale in the wind tunnel, followed by full-scale testing. However, it was not all plain sailing.

For IMSA competition, cars are benchmarked in the full-scale windshear facility in North Carolina; for WEC and European competition, the Sauber tunnel in Hinwil, Switzerland, is used. According to Holt, the numbers generated by each tunnel are different, which requires the use of subtly different components, such as a revised splitter infill, to hit the same performance window in each market.

Elaborating on the issues, he explains, “The closer you get to the ceiling on a closed jet [tunnel], the more upwash is interfering with it. The COP moved back 3.5%. Everyone goes, ‘Oh, it’s a blockage factor,’ but it doesn’t mess up the drag number so much, or even the downforce. It’s about the upwash, but it moves the COP back.”

Of course, Multimatic could have made the car more aerodynamically potent than it is, but that would have been wasted effort. “We could have had a load more downforce and been way more efficient, but it’d be way outside the box,” states Holt. Instead, the focus was on making sure the downforce was consistent and the overall package more driver-friendly. “You make that [rear] diffuser and the diffuser under the front more benign and get it to make less downforce. There are a number of ways you can do it, and one of the ways is to change the shape so it’s generating the same downforce at all ride heights.”

According to Holt, this is a very different approach from that taken with the GT, where the downforce would almost halve as ride height increased through the suspension travel. Although this may be fine for seasoned pro drivers to handle, it is not the behavior you want from a customer car.

“That’s all in service, really, of the amateur drivers in ProAm Pro,” says Holt. “Why is that important? Because if you watch this kind of racing, a lot of the time it’s the Bronze driver who actually makes the critical competitive difference. You want a car like this not to be set up for the pros who can be super quick. It’s got to be quick and easy to drive for the amateur driver.”

Although the Ford GT was a phenomenally potent race car, it was designed for one thing and one thing only: winning at Le Mans with pro drivers at the wheel. “You can’t sell a Ford GT LM car to an amateur,” Holt firmly asserts.

Easy living

Holt makes the point that no corners have been cut with the Mustang. It is equipped with what he feels are the best-quality components on the market, the idea being that these make the car easier to run and drive and, in the long term, gentler on budgets. Bosch and Motec provide the bulk of onboard electronics, with the former’s collision warning system and ABS used in addition to the ECU.

He has high praise for components such as the pedal box from Alcon (which also supplies calipers and the rest of the brake system): “That’s the best in the industry. When you go to adjust it, it doesn’t jam up and it’s really well made.” The electronic clutch actuator from Mega-Line is also highlighted: “You can go [to one program] like that, and pull away like your grandad, or press another program and absolutely launch it and never stall. It’s an incredible thing.”

The final element upon which the success (or failure) of the Mustang customer program will hinge is support. Here, Multimatic has been ramping up its capabilities.

“That part of my business has just become a monster,” remarks Holt. “We were in a small shop in Mooresville in North Carolina, where we were running the Mazdas [DPi] and doing the AMG [GT3] parts business. Now that building has become just the team to run this Mustang and build these things for customers. We’ve now got a huge warehouse down the road, walking distance, where we are running the AMG parts business, customer support and all the Porsche LMDh customer stuff out of, and then this. It’s a huge warehouse with parts and technical support hotlines, so we have become a sort of professional customer racing support company.”

Overall, Holt is adamant that everything about the Mustang has been designed to work for the customer, drawing on everything that Multimatic learned from the GT and other projects but reworked to create a car that flatters drivers across all conditions. “We’re looking at the teams, trying to make it easy to work on, looking at drivers, making it easy on the tires and being able to get a lap time at the end of 25 laps at Sebring. We want to get the same lap time at the end of that stint as you did at the beginning.”

But for all its amicable traits, no performance is being left on the table for the Mustang (within the BoP constraints). Throughout testing, Holt says, “We’re just there, right out of the box, just at race pace. We’re right at race pace all the way through the lap.”

To read more from the latest issue of Professional Motorsport World, click here