Cool heads

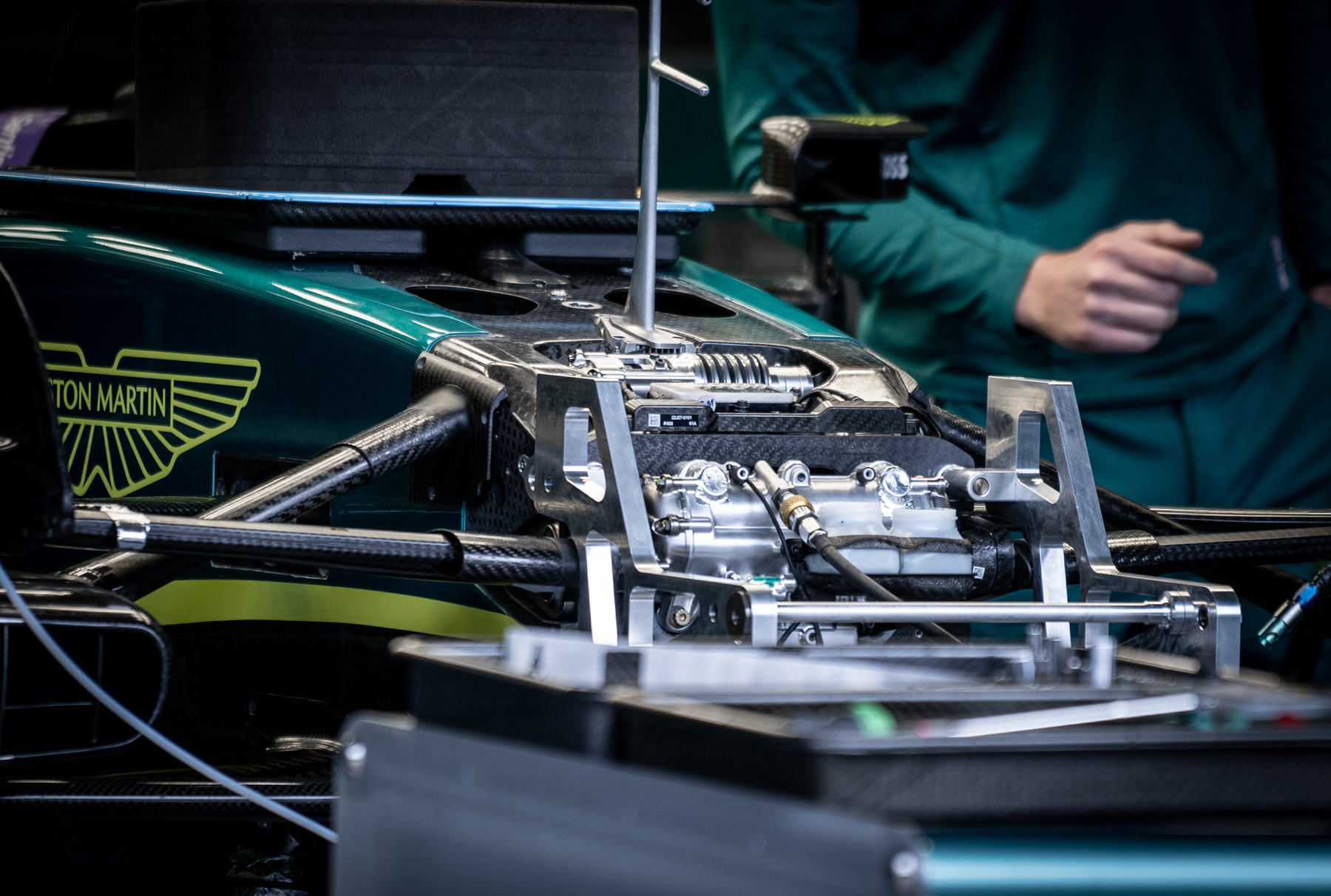

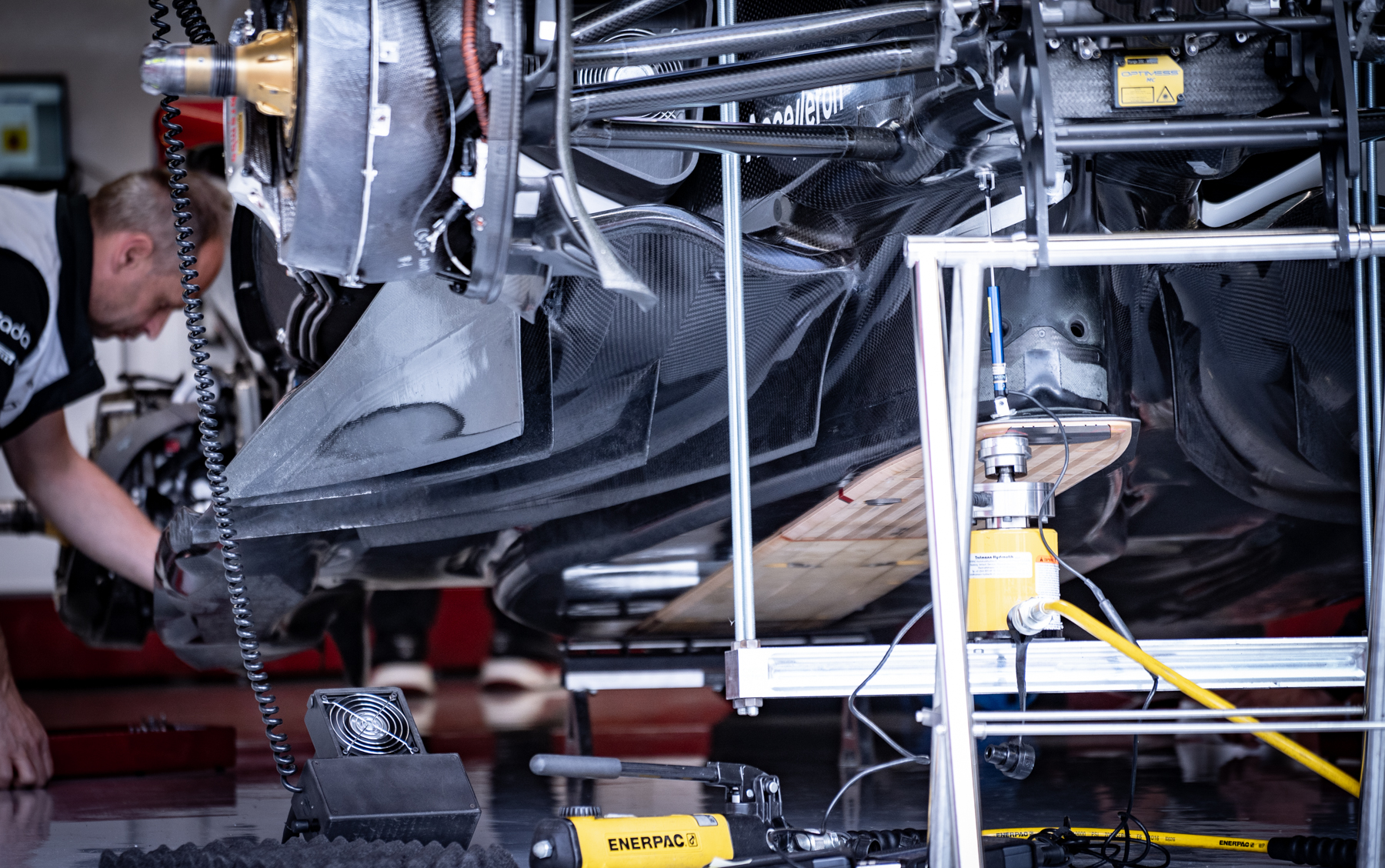

To achieve such a tight package obviously required a firm grasp of the cooling requirements of the power unit and other elements, with very little space available under the skin to accommodate heat exchangers. While not delving into details (such as the novel heat exchangers Mercedes uses from Reaction Engines) Elliot did reveal. “We’ve built our modelling capability for cooling systems over the last few years and that allows us to do a pretty good job of predicting where we’ll be at the end [of the development process]. We also do a lot of work trying to optimize the layout of our radiators.”

Mercedes has run air-water charge cooling since the current hybrid power units arrived in 2014, which Elliot admits is beneficial to its packaging approach, but not the sole determinant. “For us, we think there’s a benefit [in using air-water cooling] for the overall car package, both in terms of weight and volume. But there are lots of bits and pieces that add together to give the [end] result.”

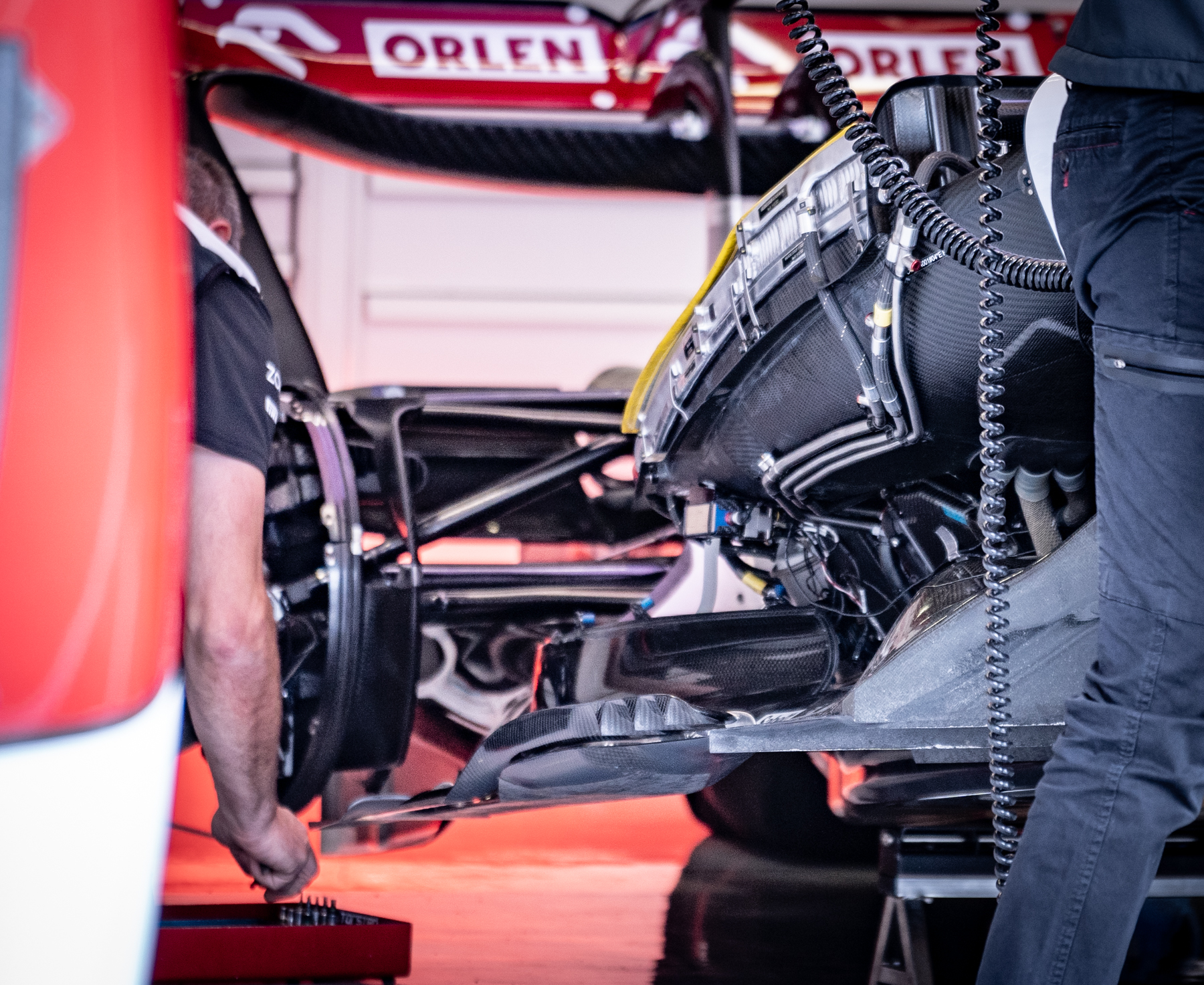

Key, whose McLaren team also uses the Mercedes power unit (but not necessarily air-water charge cooling) adds. “Cooling [with] water is very efficient, but the system can be overall heavier, and it’s pretty complicated to go to work. However, to get a sidepod package of that size, and package everything else in the back, a water (-based) system is a pretty efficient way to try and achieve that.”

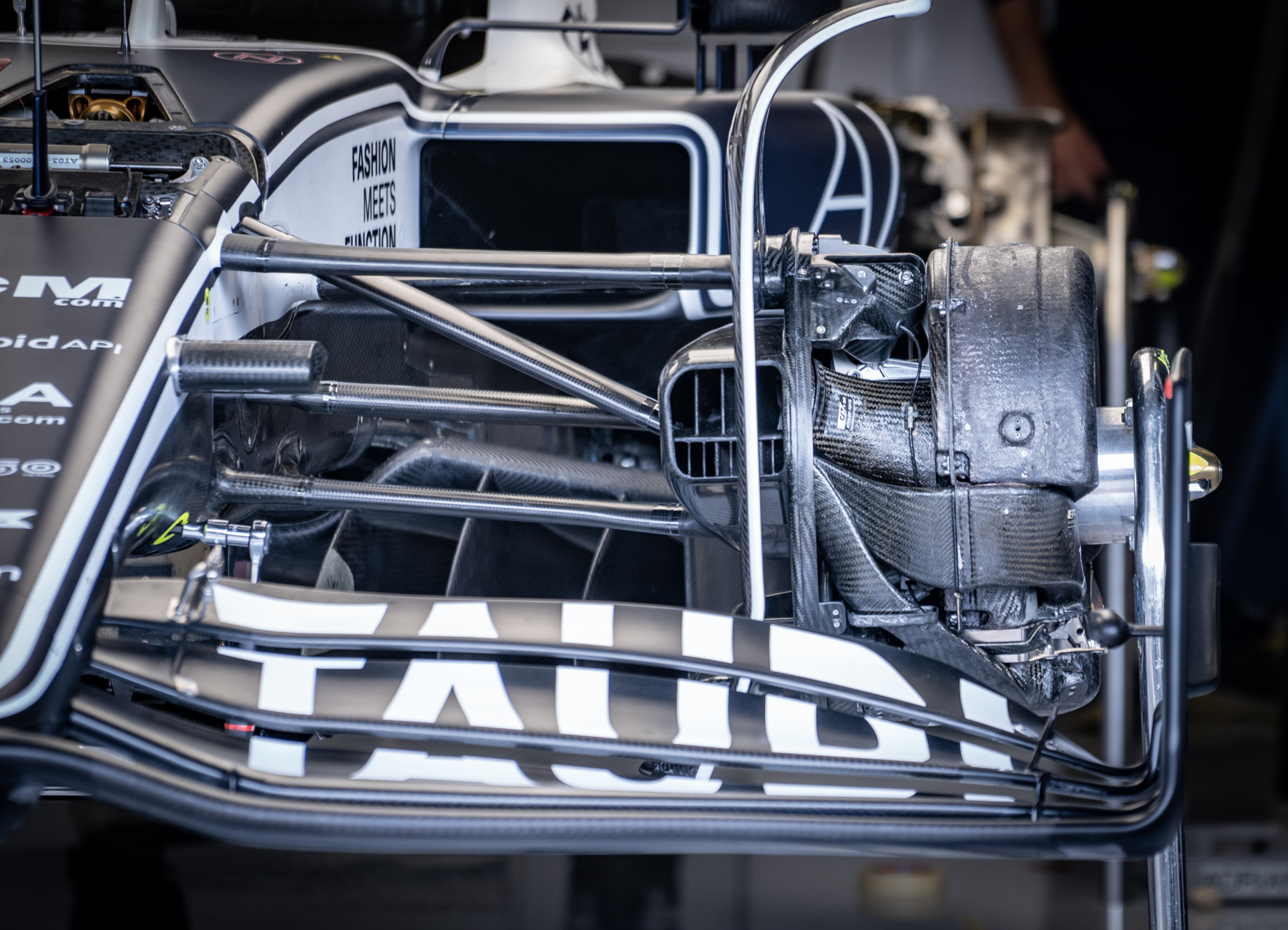

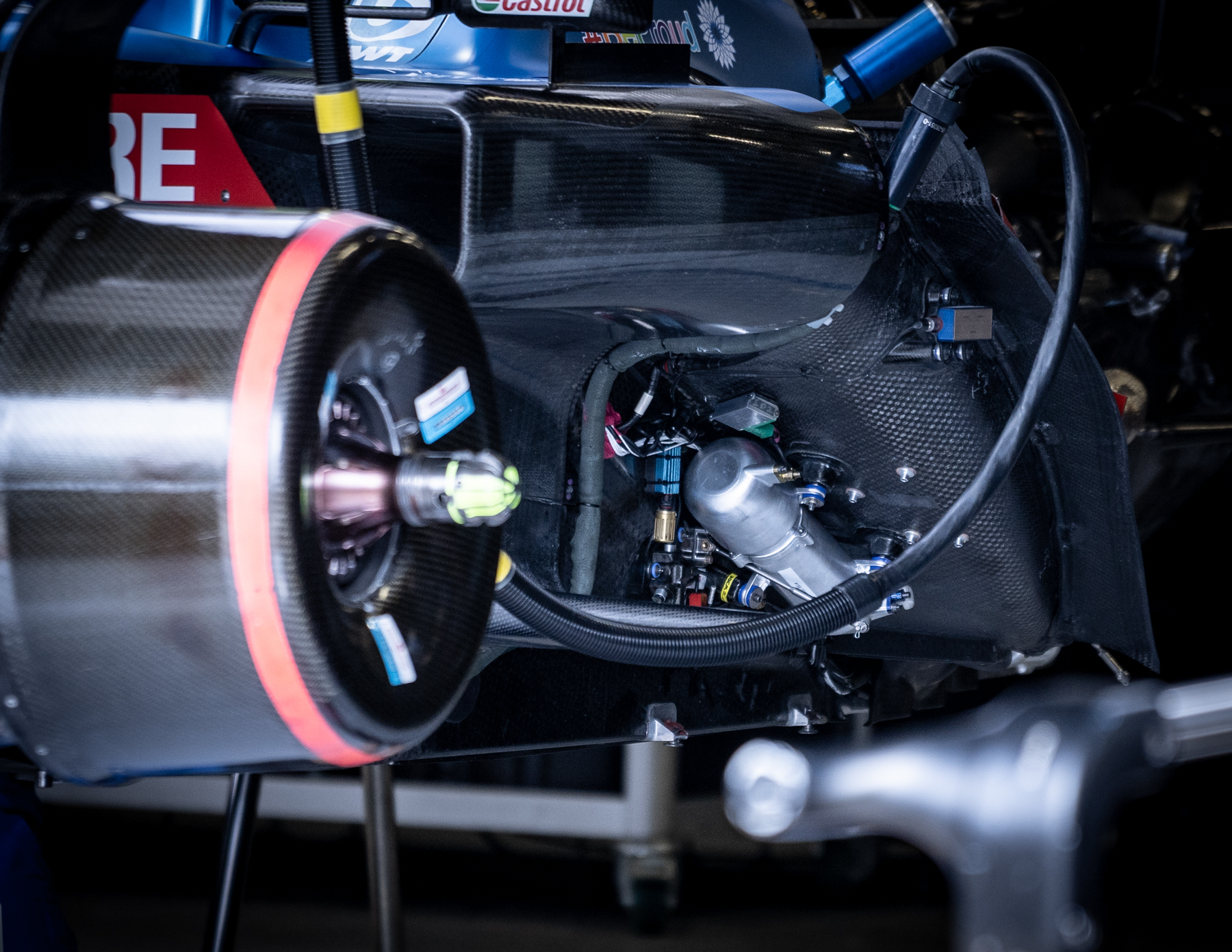

Though it has taken a more voluminous approach to sidepod design, Alpha Tauri’s Egginton did say that potential for a tighter package was baked in at the concept stage of its car. “We’ve ‘packaged protected’ to give ourselves a lot of scope, for example, with sidepod packaging, and we haven’t really used a lot of that package protection yet, it’s available. The last thing you want is to come up with fantastic aero development, and then having to redesign a lot of mechanical bits underneath it.”

From Resta’s perspective, again, the choice of a chunky sidepod design proved beneficial beyond its aerodynamic contribution. “I think we probably had an easier life than last year in terms of packaging,” he says. “Because we’ve got a slightly larger bodywork than some of the others. We had a bit more margin to packaging, radiators and other parts.” This reasoning applied to several other teams, with one engineer observing that numerous ancillary components, such as electronics control boxes, were situated quite differently compared to 2021, thanks to the space made available by some car concepts removing the necessity to cram everything tightly along the centerline of the cars.

In Mercedes’s case, the introduction of new wheelbase limits also had a considerable impact on how it packaged the mechanical components of its car, having previously run one of, if not the, longest wheelbase on the grid. “We had quite a lot of packaging work to do because of that,” says Elliot.

Weight challenge

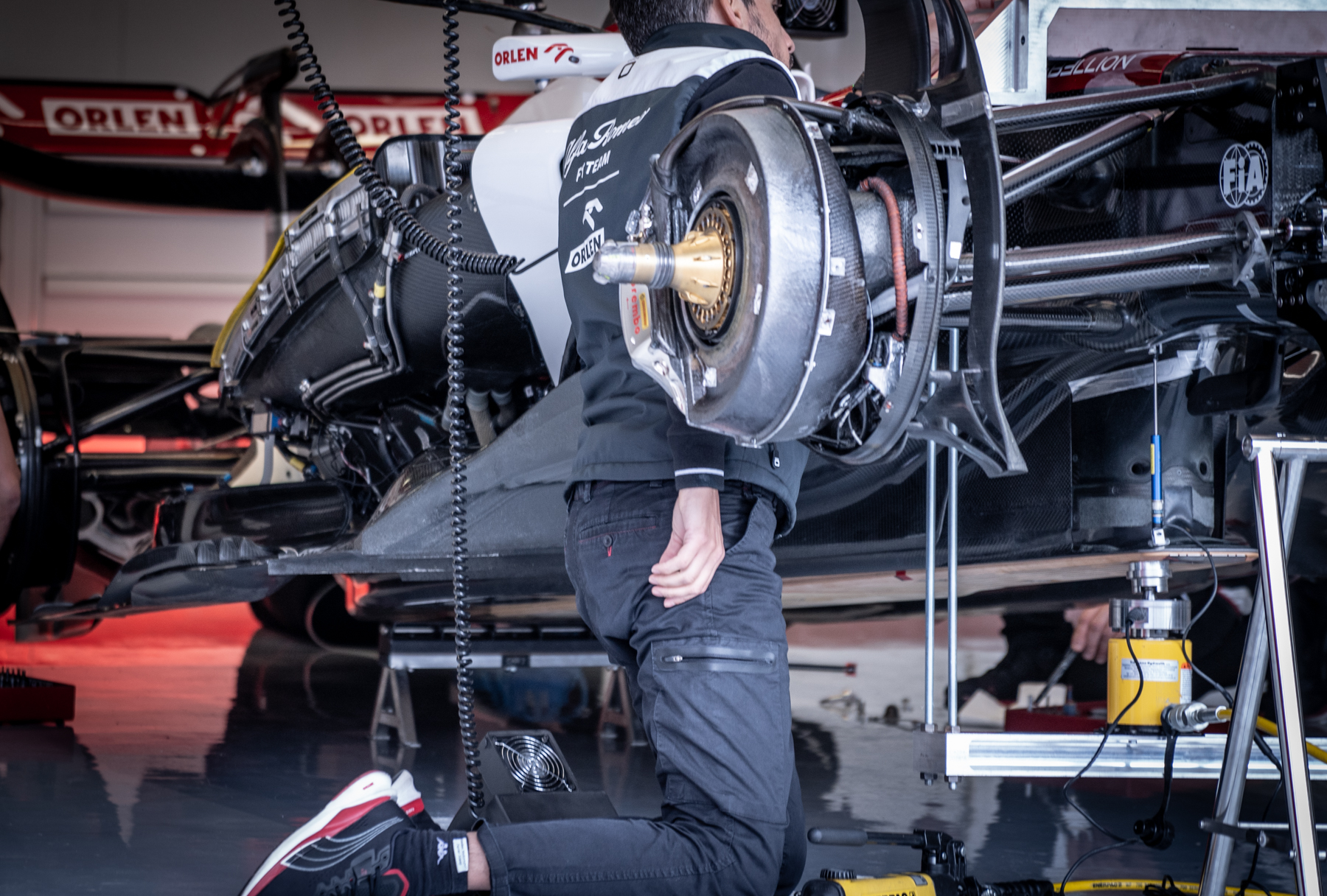

Nearly all the teams on the grid have been battling to bring their cars down to the regulation weight limit (798kg dry). This is a subject Elliot expands on, noting that one of the main drivers of weight increase, carried through from the ’21 regulations to ’22, was the introduction of a new size ‘squeeze’ test on the chassis. “It was huge, difficult to pass and therefore everybody had to add a lot of weight into their cars,” however, it was not the only contributing factor. “I think the nature of the aerodynamic oscillations we’ve seen this year has also driven people to stiffen their cars in certain places that it’s not helped,” he adds.

Regarding Mercedes’s issues with car weight, Elliot admits that it was overweight at the start of the season, and even moving into the second half of the year, was still not on the weight limit. “We’ve done a lot of work to bring the weight down, but we have also added more back on with various [development] pieces.” He explains that though weight is always a big talking point, once the lower limit is hit, there is little more to gain. Conversely, “if I was to say we’re on the weight limit, I can give you aero upgrade.” The same logic applies to reliability upgrades and this horse trading is a fact of life for those tasked with considering overall car performance.

This constant battle has forced some teams to extreme measures, with Red Bull going so far as to introduce a new chassis homologation, said to be some 4kg lighter than the one it brought at the start of the year. How the team achieved this within the constraints of the budget rules was a topic of some debate but highlighted just how challenging mass control is on the current generation of cars.

Overall, the 2022 F1 regulations have provide a fertile playground for engineering development and while convergence of ideas is ultimately inevitable, it will be some time before that point is reached.

Bouncing along

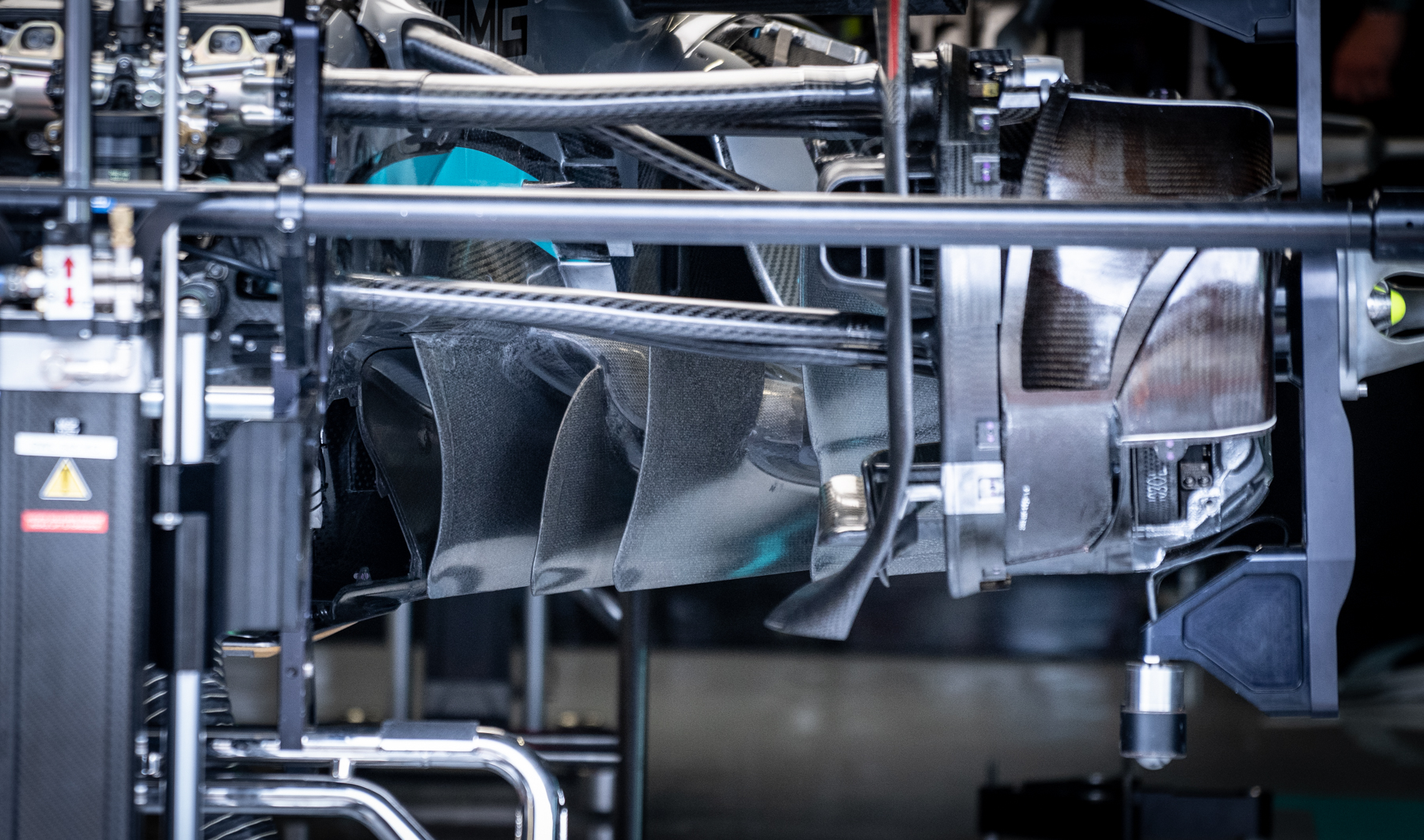

One of the biggest talking points of 2022 has been the reappearance of ‘porpoising’ in F1, whereby the cars enter a rapid vertical oscillation at high speed, due to the downforce pushing the underfloor into the track surface, stalling the airflow. This stalling rapidly reduces downforce, the car rises back up on its springs, and the process repeats itself. Some teams have appeared to be more susceptible to the issue than others, with Mercedes one of the former.

The greatest challenge was that due to the nature of the phenomenon, the first most teams knew of it was when they arrived in Barcelona for pre-season testing. Mercedes’s Elliot admitted his team had not seen any evidence of a problem during its wind tunnel and CFD simulations. “We weren’t really expecting sort of the bouncing issues, we’ve seen.” Expanding on the mechanisms at work, and the fact that porpoising in its true sense has been replaced by bouncing, he continues.

“There’s an aerodynamic element, which is because we’re adding energy into the vertical motion of the car, which means you’ve got a phase shift between the aerodynamic load and the position of the ride height of the car. That creates an energy input that’s more than the dampers can deal with [causing the porposing]. Then there is the fact that we’re having to run these cars so low to the ground with so much downforce on them, that you must run really stiff. And I think that’s also causing quite a big consequence.”

Alpha Tauri’s Egginton suggests that there were indications late in the AT03’s development process, but “we didn’t really know what we were looking at.” He points out that it is exceptionally hard to replicate in a moving belt wind tunnel as, “touching the belt [with the car] is not preferred!”

He goes on to note that as the nature of the 2022 underfloor design rewards running as close to the ground as possible to extract best performance, teams would push to the edge of the envelope at which porpoising becomes an issue. “If you have to lift the ride height, you give away a big chunk of performance and that is the reality of the regulations. So it’s finding ways to exploit the regulations as best as you can, avoiding this banana skin for porpoising and a car that’s incredibly difficult for the driver to handle. It’s a trade off.”

The knock-on effect of very stiff setups being that at some tracks, drivers voiced complaints about potential health implications of cars bottoming out hard, with the FIA prompted to issue a technical directive and regulation tweaks to monitor the situation and, if necessary, force teams to raise their ride heights.

Push me pull you

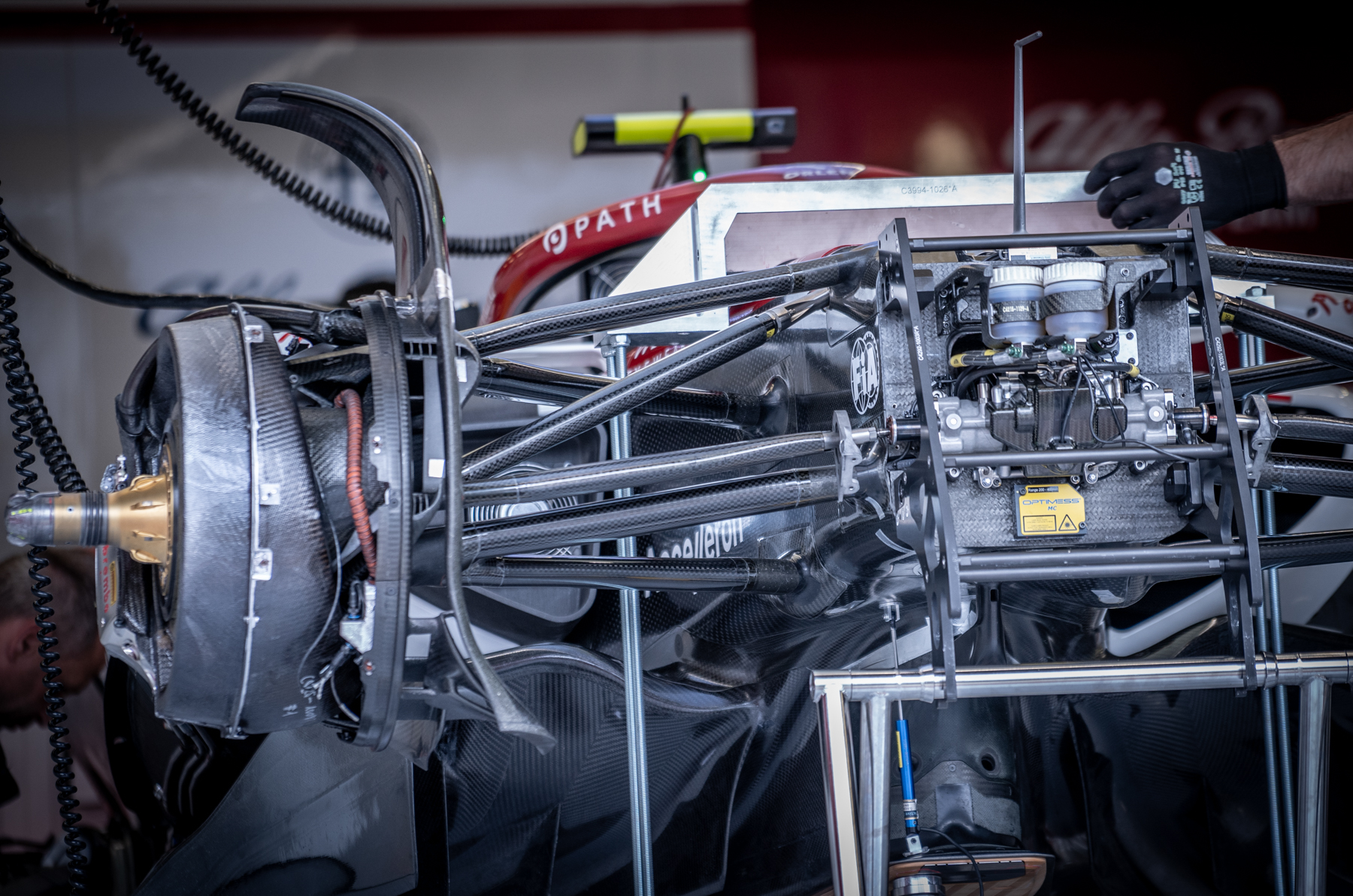

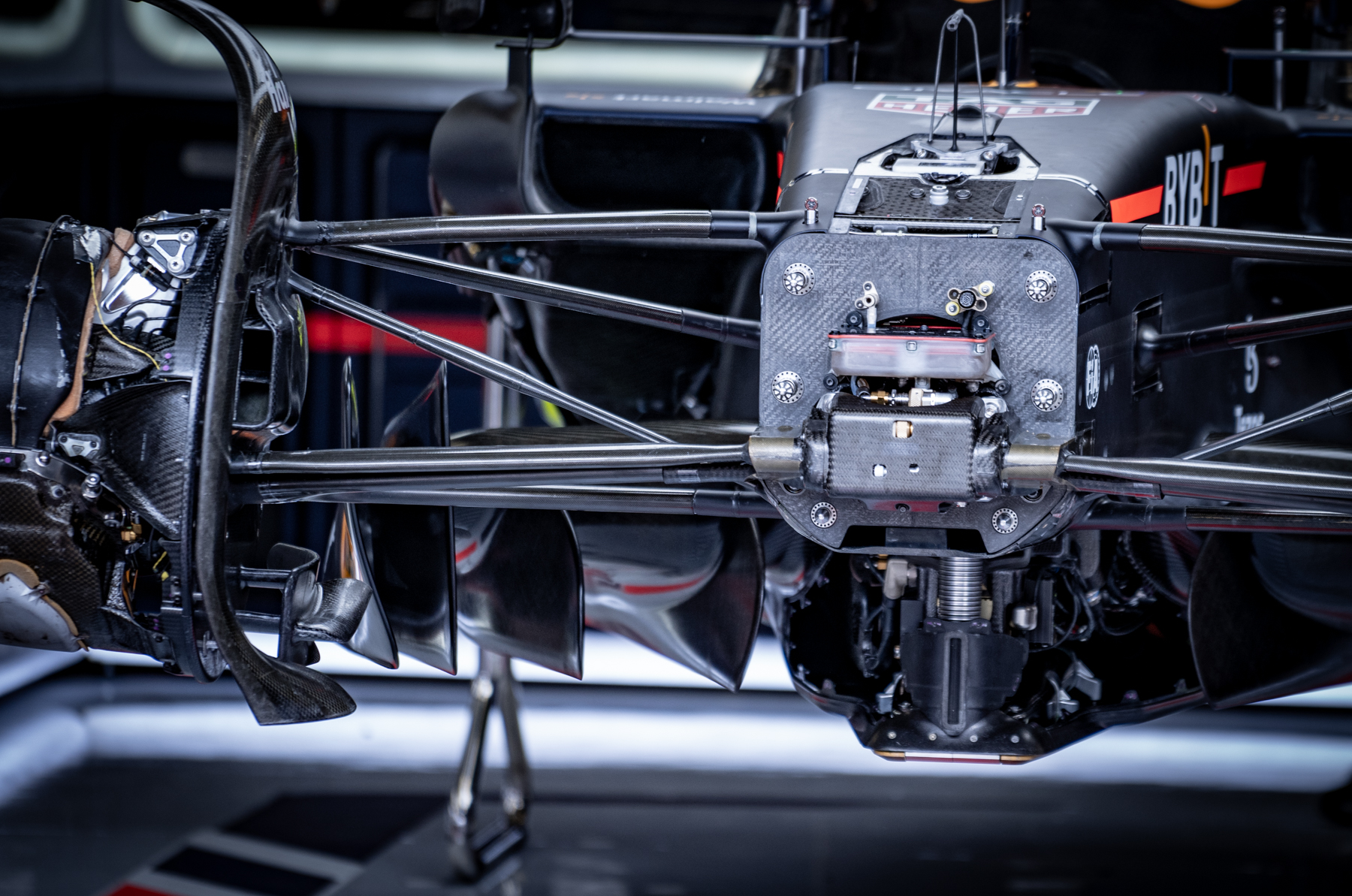

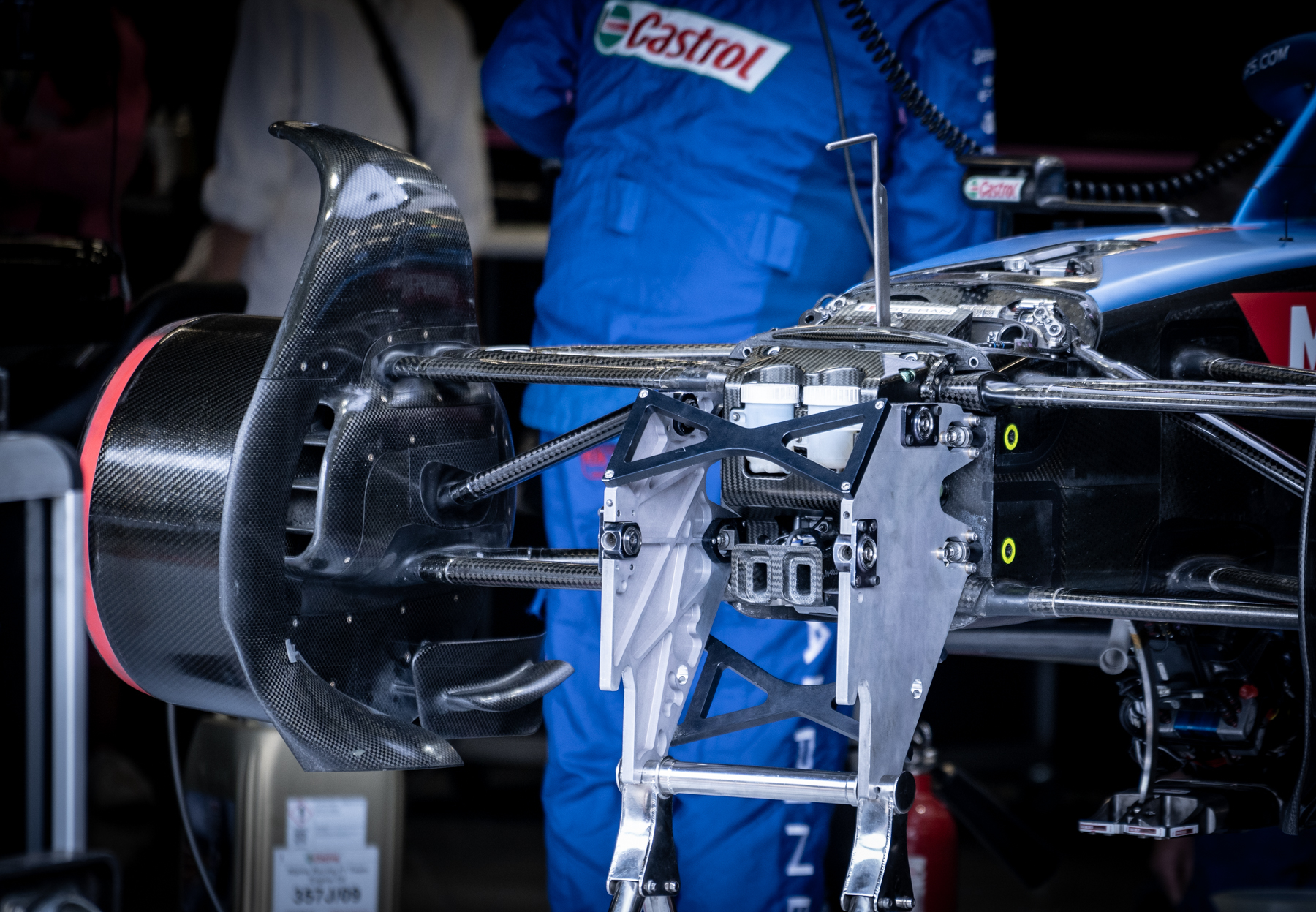

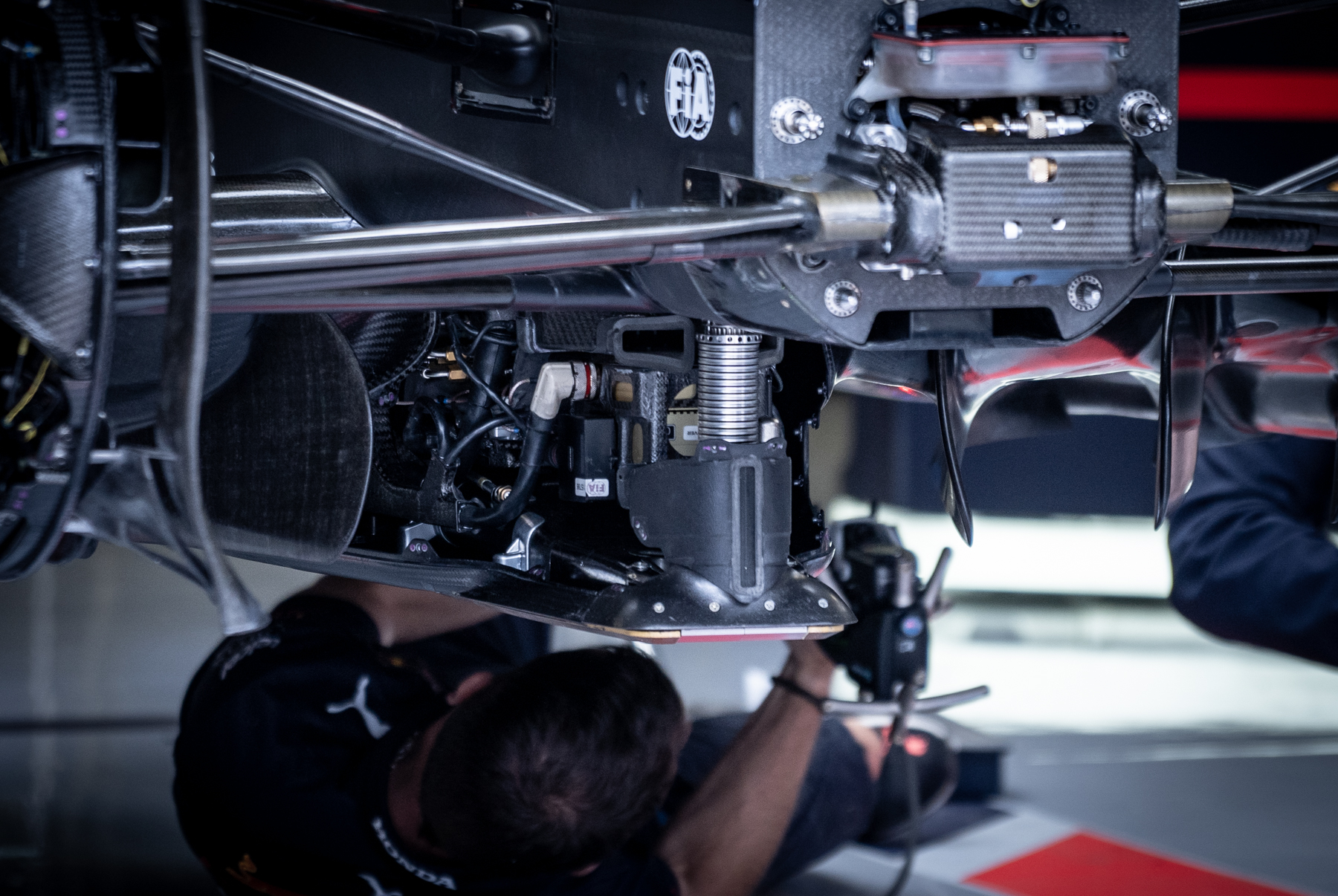

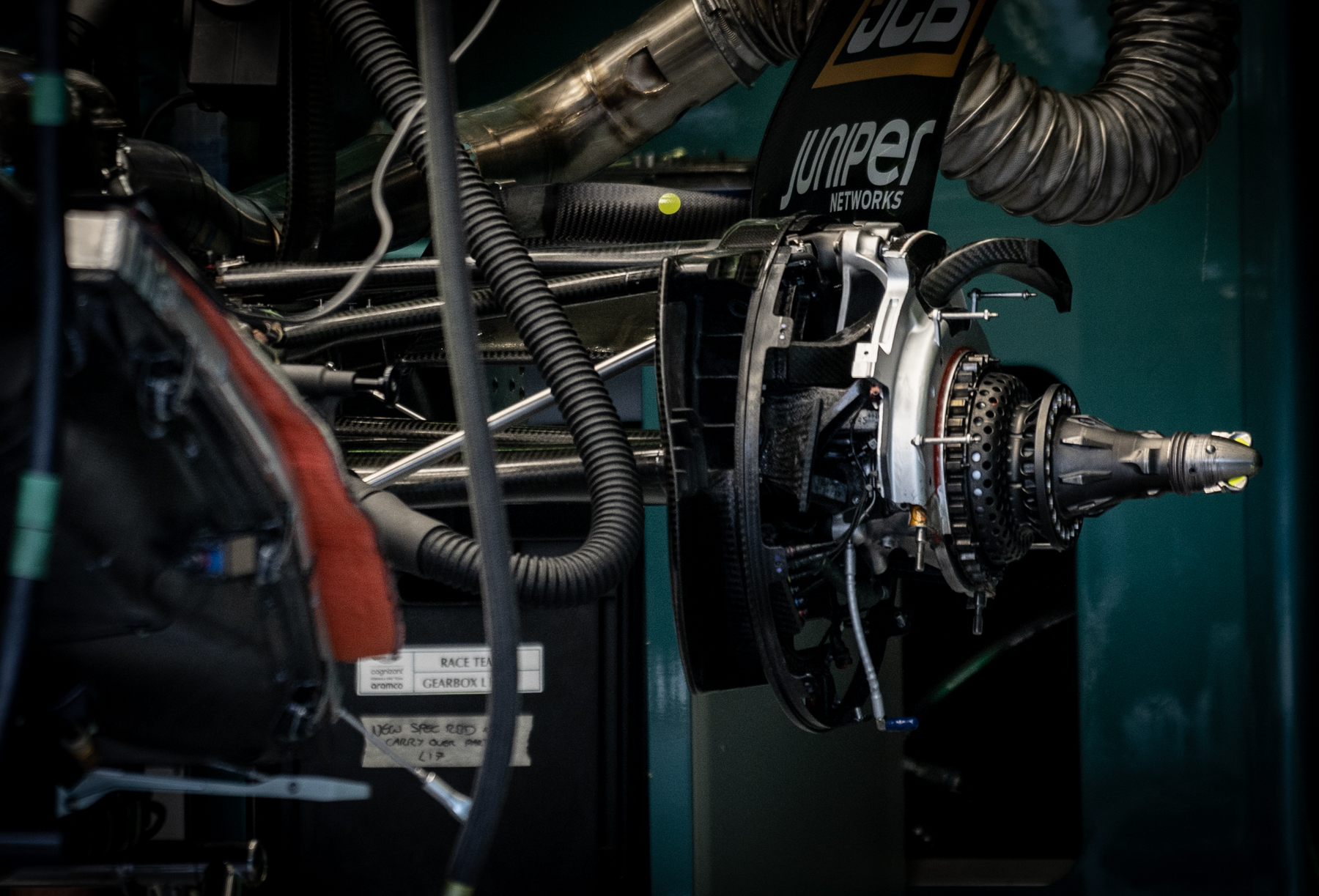

2022 also saw the return of pull-rod front suspension as a concept in F1, with McLaren, Red Bull and sibling team Alpha Tauri running this arrangement. Explaining its choice, Egginton says that for Alpha Tauri, the pullrod layout complements its overall aero concept. “With both a push rod and pull rod, you can achieve the kinematic effect you want, but there is a lot of aerodynamic influence there. It is a decision you need to make relatively early, because of how it is tied in with chassis development.”

The choice to go with either setup, he says, is tied to the front wing and floor philosophy, and the influence the pull or push rods will have on the flow structures coming off the wing, particularly at areas such as the junction between pull/push rods and the wishbones. “We went for pull rods, because, at the point we had to freeze the design, they gave the most performance on the car.” He does, however, caveat, that floor and wing design continues to evolve, whereas “it’s unlikely anyone is going to switch from pushrod to pull rod mid-season. You lock it [your concept] in and develop around it. For us, it gave the fastest car and potential for development. That isn’t to say things couldn’t change in the future though…”