The infamous Nordschleife layout of the Nürburgring is unlike any other stretch of racetrack in the world. From the perspective of a suspension developer, it is a nightmare, requiring two normally mutually exclusive characteristics from a car: good bump compliance to handle the rough surface but also excellent platform control, to provide stability on the high-speed sections and through its various compressions and yumps.

Damper manufacturer KW Automotive has made its reputation on the sinuous Green Hell, and some of its developments over the past 20 years have seen suspension setups evolve from being rock hard and somewhat wayward, to providing drivers with previously unheard-of levels of compliance, while not compromising on aerodynamic or chassis stability. It’s latest damper designs, used by competitors including the works Porsche GT3 outfits, are based around a four-way, high- and low-speed compression and rebound adjustment system, coupled with a solid main piston.

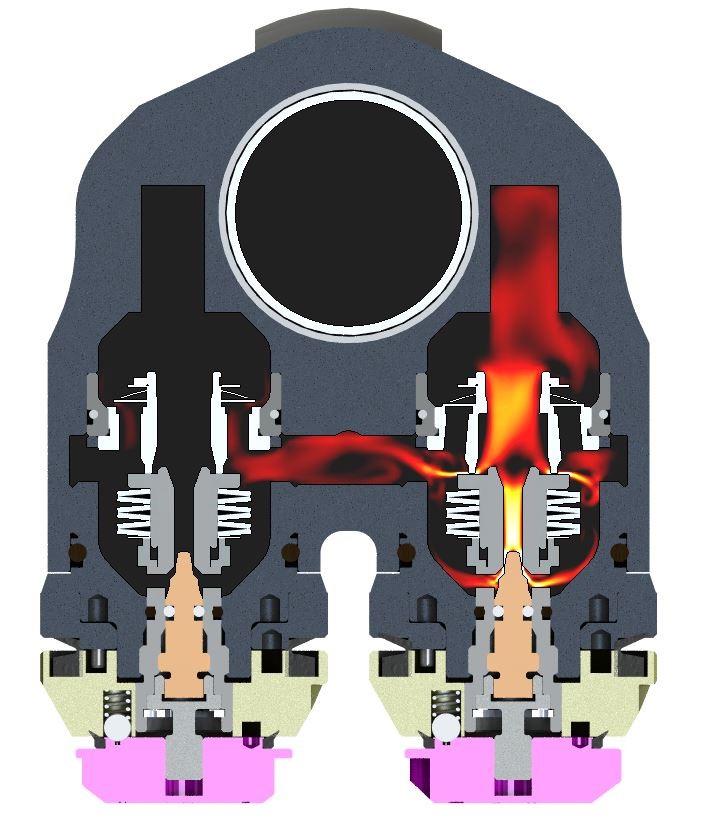

As Thomas Rechenberg, head of motorsport at KW Automotive, explained to PMW, “We switched to a four-way adjustable damper and a solid piston at the same time, the idea being that the large area of the piston reduces the oil pressure in the damper. It’s not a new idea, Ohlins and Multimatic have done it before, but we also combined it with a new valve design and also now use a second tube inside the damper, which helps to drive down the hysteresis.”

Rechenberg noted that the compression and rebound valves have a very short length, and the low-speed control is incorporated within the high-speed valve body. This compact packaging means the company has been able to incorporate the design in both traditional remote reservoir damper units and also inline versions, a useful advantage where packaging space is limited.

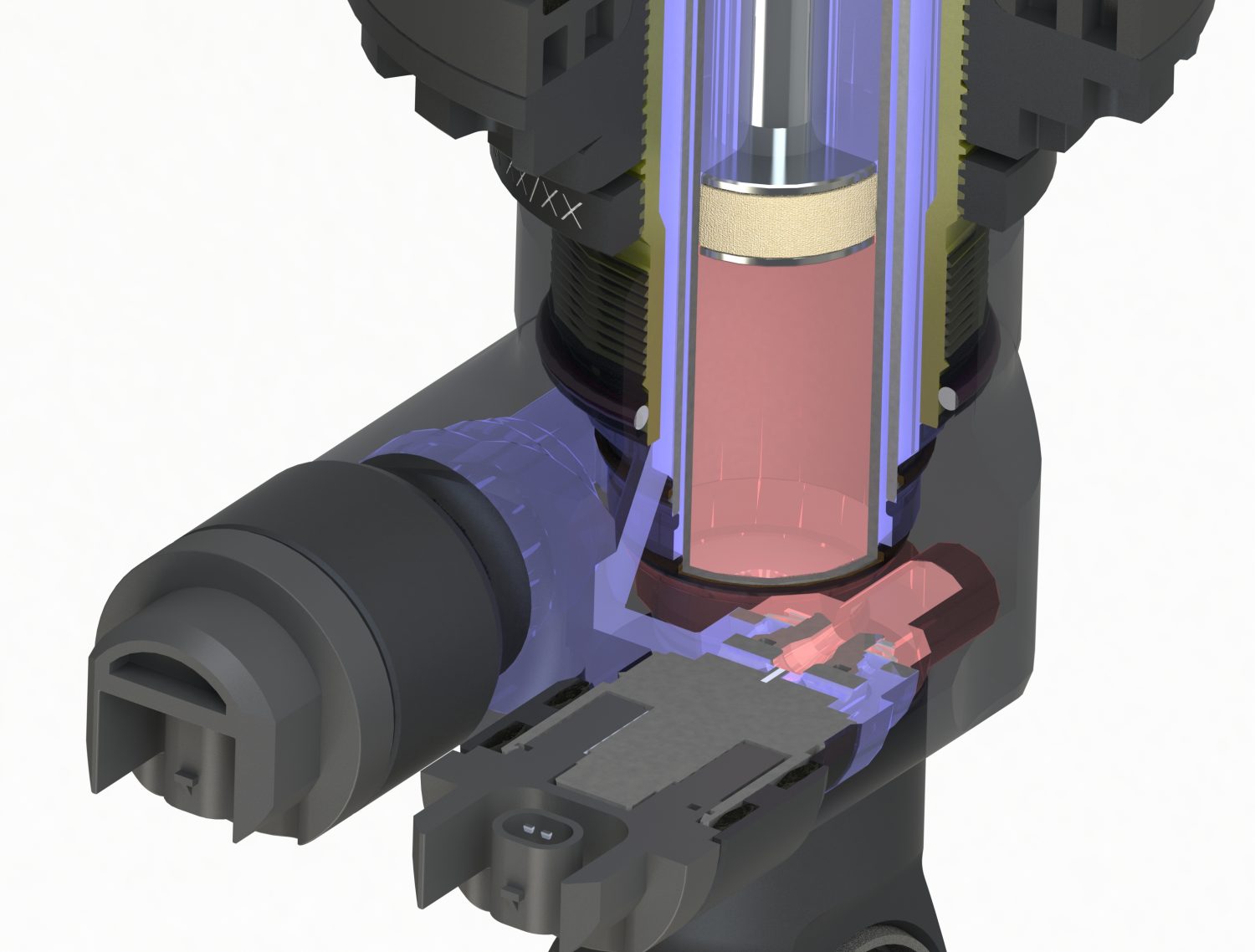

The compression circuit valves also incorporate Belleville springs, which act as an internal blow-off system. “The Belleville springs have the advantage that you open up a large cross-sectional area in a very short travel, the damper is fully open after only 0.5mm of travel [in the Belleville spring]. That means you can run really hard damping without disturbing the car on the curbs, the blow-off can also come much later than on a conventional design. Normally, you would need the damper to open at [a damper speed] of around 0.3m/s, we can open at 0.5-0.6m/s,” summarized Rechenberg . The use of an x-ring to seal the gas piston has, he said, also led to a considerable reduction in friction.

Rechenberg highlighted that development of its current dampers has been shaped by the very specific demands of the Nordschleife, with the latest design originally developed for BMW’s M6 GT3 car, which initially had issues with front damper breakages (another brand’s).

Since initial deployment in the M6, KW’s damper curves have been extensively developed using a seven-post rig, with the testing focused on accurately replicating the aero loads experienced on the Nordschleife, a stern test for both rig and car. “They were frightening at first, with an M6 on the rig driving the section onto the Dottinger Hohe, we thought we may need a new car and rig,” recalls Rechenberg.

With the majority of GT3 cars now featuring strain gauges as part of their datalogging systems, KW was able to leverage said data to define its rig tests. Rechenberg remarks, “We know exactly the forces going through all four corners. We looked at the sections of the Nordschleife where we felt the most gains were to be found and were able to compare the force data between the rig and track, and ensure the forces were the same within a tolerance of about 4%.”

Overall, Rechenberg said the rig program allowed KW to tune the damper and spring setup to one that used a softer rate spring, while still providing the necessary platform control: “We definitely found a better mechanical setup overall.” Impressively, KW ended up running spring rates similar to those found in GT4, but on the far more aero dominant GT3 car.

Significantly, Rechenberg points out that when it comes to the specifics of the Nurburgring (and some other tracks such as Spa, with its heavy compression into Eau Rouge), it is the final few millimeters of suspension travel that can prove most important; in the case of the Nordschleife, there are at least five points on the track where a car will run through its entire suspension travel.

Further complicating matters is the fact that the ideal ride height on track is around 30-40mm, in order to make best use of the underfloor aero, but GT3 has a static ride height rule of 70mm. Running the cars at the ideal ride height requires a soft spring, but this can lead to significant instability and complaints from drivers due to an unsettling transition on and off the bump stops (which have a much higher rate than the springs).

“At Pflanzgarten you have a very high damper speeds, because the car is landing [from a jump over a crest], then heading up a hill into a right-hand corner. The suspension stays very compressed, running on those last few millimeters of compression. If you want to keep off the bump stop in those areas, you can do that with a stiffer spring, but the car will then suffer around the rest of the track,” Rechenberg says by way of example.

In order to balance the need for a soft setup, but retain suspension control even under high compression forces, KW developed a new bump stop material that provides a degree of rebound damping when engaged, aiding stability. “We wanted to create a situation where the car would remain compressed for a few tenths of a second then come up smoothly off the bump stops,” Rechenberg says.

The work KW has conducted in the development of dampers that can handle the specifics of the Nurburgring highlights the specific nature of the circuit’s challenges. However, Rechenberg was at pains to point out that the learnings can also be applied to other circuits that may not be as extreme. The company is now also involved in off-track racing endeavors. Having acquired rally and off-road suspension specialist Reiger at the end of last year, it recently celebrated Stéphane Peterhansel and Edouard Boulangers’ win on the Dakar in a Mini JCW Buggy equipped with its dampers.