Peugeot has returned to endurance racing with its striking wingless 9X8, picking up the brand’s often left-field take on sports prototype design where it left off back in 2011. The 908 LMP1 was nothing if not innovative, though Peugeot kept a tight lid on many of its technical highlights, even after the project was canceled. One great example of the team’s clean-sheet thinking was the transmission, which enabled the prodigious torque output of the 908’s 5.5-liter turbo diesel to be harnessed without the need for a gearbox resembling something out of a heavy truck.

Turn the clock back a quarter century and transmission failure was a common occurrence at Le Mans – notably recognized by Audi, which engineered its R8 LMP so that the entire gearbox assembly could be swapped out in minutes (as it demonstrated at the millennium running of the 24 Hours). By the mid-2000s, when Peugeot Sport was designing the 908 HDi FAP LMP1, matters had improved considerably. However, the torque potential of the newly arrived diesel powertrains was set to place transmissions under previously unseen loads. Peugeot’s V12 twin-turbocharged diesel could produce around 1,500Nm of torque – double that of a contemporary gas-powered race engine.

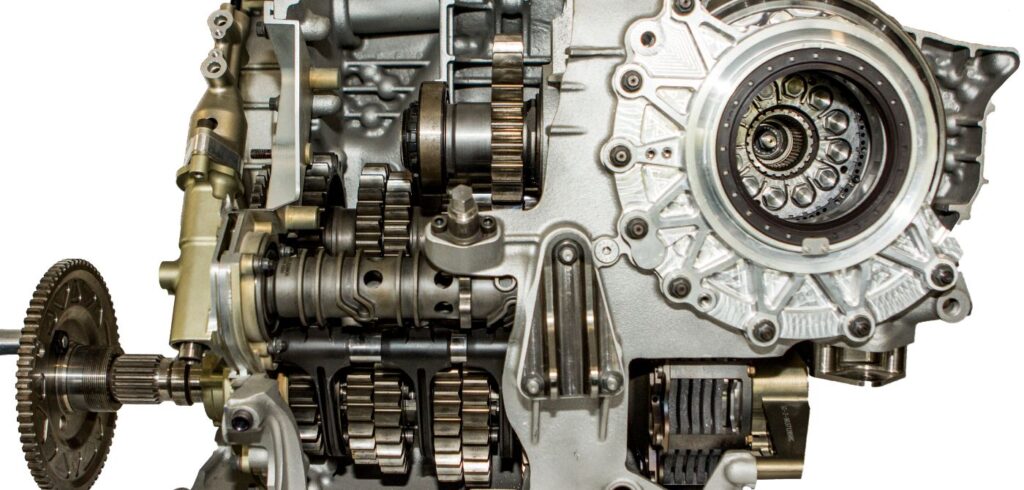

Peugeot turned to Ricardo to assist with the design, development and production of a suitable gearbox, initially looking at a five-speed unit. This was the maximum number of gears it was thought could be accommodated within a reasonable-size casing, with the mammoth torque negating the need for more speeds. However, Ricardo had different ideas and persuaded the French outfit to move over to a six-speed, which would better utilize the V12’s power band.

This is where the design got interesting, literally flipping convention on its head. To achieve the layout Peugeot desired, including a clutch at the rear (for easy access), Ricardo designed a transmission with the input shaft directly connected to the end of the crankshaft. The input ran inside the primary shaft to the clutch (at the tail) with the clutch basket affixed to the end of the primary shaft, transferring drive to the primary when the clutch was engaged. The final drive and differential sat above the clutch housing.

The key innovation with the 908 transmission, compared with any previous racing unit, was that the dog rings and plain bore gears were located on the primary shaft, with the fixed gears on the secondary shaft – a reversal of normal practice. This solution was reached after Ricardo looked at its existing transverse LMP1 transmission, which had an input torque limit of 750Nm. When the normally applied 2:1 reduction was applied through the gears, the secondary shaft on these units would see 1,500Nm. This meant that the shift forks, dog rings and other components Ricardo had already deployed at Le Mans could withstand the forces they would see direct from the 908’s engine, but only if they were used on the primary rather than the secondary shaft. By flipping the role of each shaft, the size and weight of the components could be kept down, freeing up space to incorporate a sixth ratio. The torque would then be multiplied through the ratios and final drive, netting a simply astounding 3,000-4,000Nm at the driveshafts and hitting Peugeot’s design targets.