iVT Expo took place on June 26-27 in Cologne, Germany, bringing together industrial vehicle component suppliers and manufacturers from around the world. As with the automotive industry, the electrification of powertrains in the heavy-duty and off-highway markets is gathering momentum, with many of the same challenges – a need for ever greater energy and power density, cost effective production methods and increased range or operating time.

Starting small, Turntide displayed a range of compact, low-voltage inverters. It states that its new Whitehaven product line offers one of the highest power densities on the market (34.6kW/L, 36.1kW/kg) and excels in low-voltage electrification applications below 100V, providing precise torque and speed control for IPM, SPM and IM motors.

“The range is specifically tailored for the two- and three-wheel market – last-mile delivery vehicles, for example,” said Chris Pearce, technical director of advanced engineering at Turntide. “It’s a fully featured replacement for our previous generation of products. It features dual CANbus, multiple-motor encoder support, and can run both permanent magnet and induction machines. The key differentiator is an independent microcontroller we are providing for the customer, to allow them to customize the logical behavior and function of the inverter. Out of the box it has its own vehicle control function, which is a model-based system with torque modulation done in a multidimensional way, taking in a complete set of target points.”

Solid state batteries

Another particularly noteworthy product was from Italian company Aliant Ultralight Battery, which unveiled a solid-state battery system at iVT Expo. In this interview, export sales manager Riccardo Massaro emphasized the safety and dependability benefits of the solid-state chemistry battery compared with NMC technology and reveals that the company aims to launch a market-ready prototype within six months. He also noted that power density is comparable to its existing LFP products, however, cycle life still needs improving to reach parity with more mature technologies.

Power dense motors

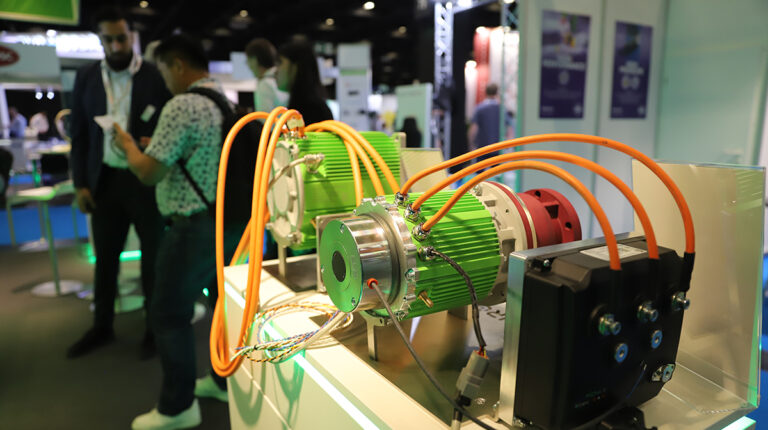

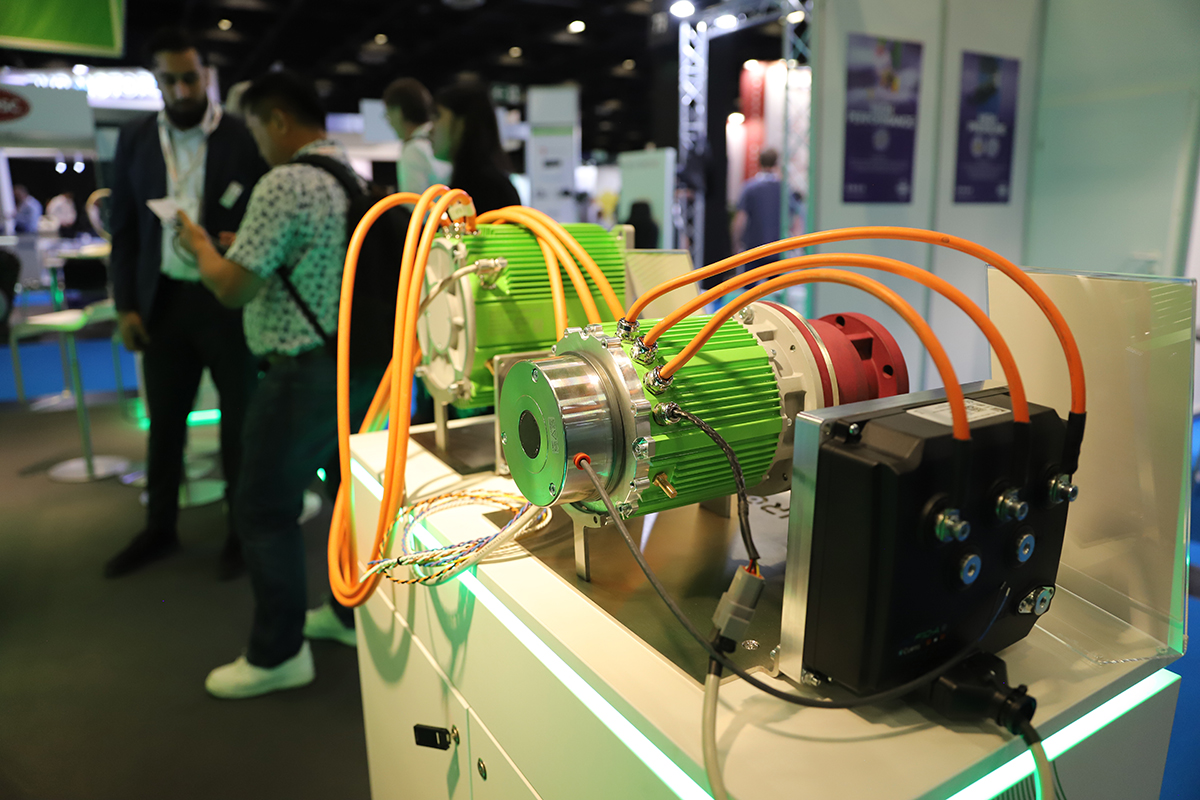

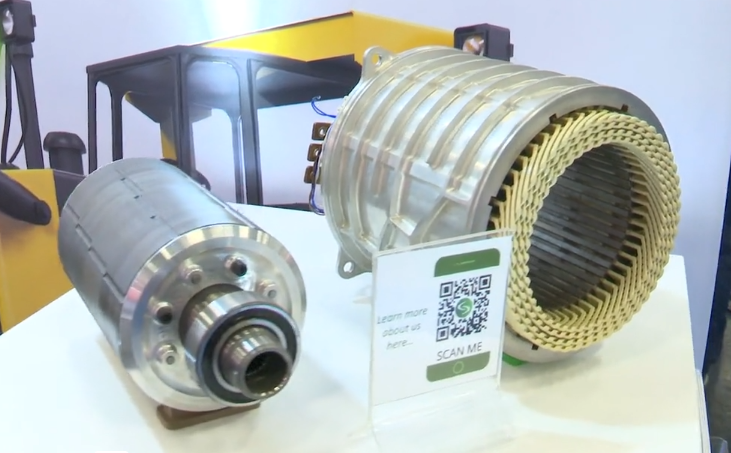

There were plenty of electric motor manufacturers in attendance. EVR Motors displayed its impressive range of traction motors, which use soft magnetic composites (SMC) instead of traditional steel stampings for the stator. This enables a unique architecture, which, when coupled with efficient cooling (both air and water), results in impressive power densities.

Moving up in size, Engiro showcased a 370kW motor specifically designed for heavy-duty applications. Head of sales Fabian Schneider explained that the motor’s performance is enhanced by power density, efficient coolant and high copper content. It features water-jacket cooling and an aluminum housing for optimal heat transfer, with options for rotor package and bearing replacement.

Playlist

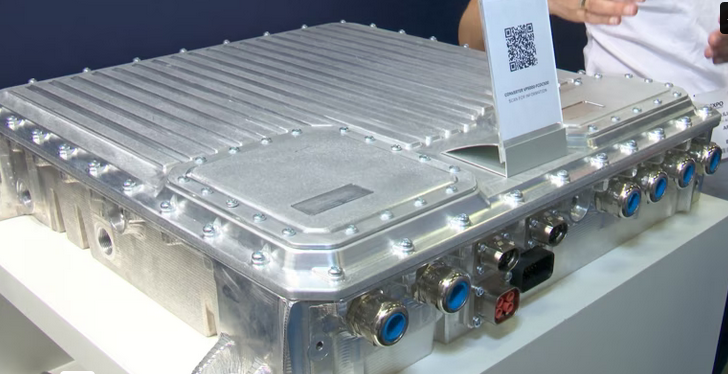

Power electronics

A host of power electronics solutions were also on show, with companies such as Drive System Design, Aradex and Suncar all exhibiting high-voltage capable, rugged inverters and DC-DC units for heavy vehicle and off-highway applications.

Playlist

Full highlights of iVT Expo can be found here.