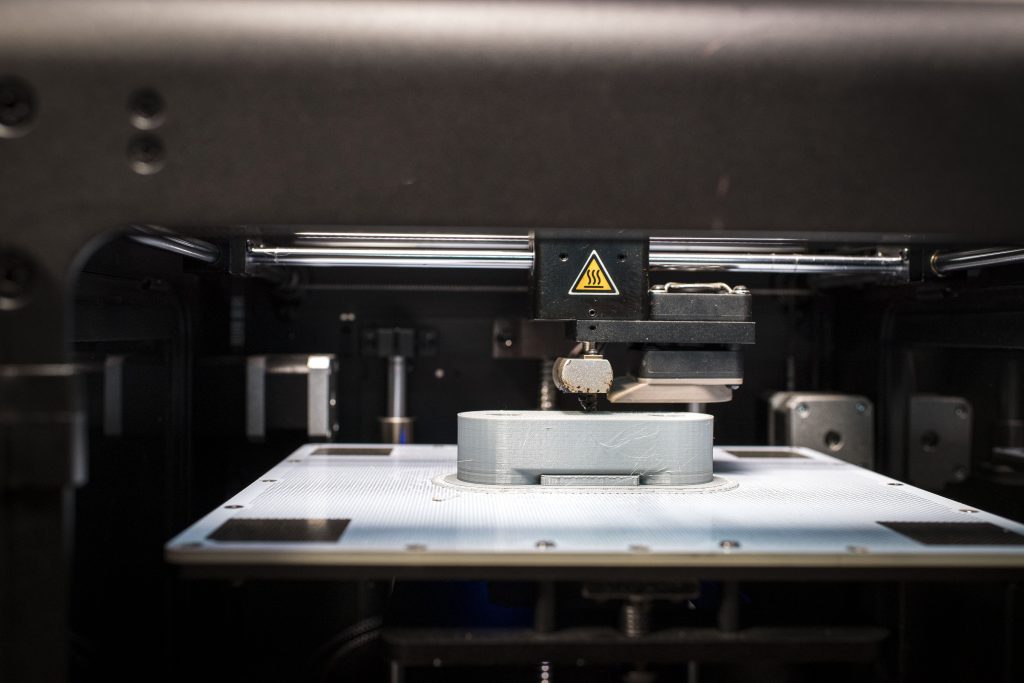

BMW Motorrad Motorsport says it has begun deploying a portable 3D printer trackside to speed the development of new components for its World Superbike race program.

Motorsport director Marc Bongers said, “This technology allows us to make improvements to the RR quickly and efficiently. The development of a WorldSBK bike is an ongoing process and it is often the minor details that make a motorbike better.

“Behind the scenes, our engineers are always working on adjusting and optimizing individual bike components, all within the framework of changes permitted by the regulations. We can use 3D printing to implement these at the racetrack, even during race events. We then take the acquired data and the subsequent analyses – combined with comments from the drivers or input from the mechanics working on the bike itself – and generate input for the development team.

“This input contributes to the emergence of ideas that can be implemented directly in existing constructions or in simulations and iterative processes that lead to new constructions, all of which are executed in CAD. The new components are printed as plastic variants and their functions and ease of installation are checked on the bike. This process is now much faster than when we had to wait until the parts were produced either internally or externally and made available for evaluation at the racetrack. It is also easier to evaluate potential touching with surrounding parts or restricted access than it would be on screen.”

Another advantage of having a printer trackside, noted BMW, is that if an adjustment is required, it can often be made to the existing plastic part and then implemented in CAD. This process can be repeated as often as required, until the part corresponds 100% to the requirements.

The team flagged up an example of the system in action from the recent WorldSBK double-header at Jerez (Spain) and Portimão (Portugal). In Jerez, the linkage system of the bike’s rear shock absorber was optimized, based on the riding data. A prototype of the 3D-printed part was installed and tested for fit. The final data was then sent to a supplier, who manufactured a new linkage system between the race days. A few days later, in time for the start of the next race weekend at Portimão, it was available for installation on the BMW S 1000 RR.

The team points out that if smaller components or spare parts, which are not subject to such extreme stresses, need to be manufactured, the complete process can take place on-site with the 3D printer. Examples for such parts include adjustment levers, sensor holders and quick-release couplings.

However, if the printer on site at the track doesn’t have sufficient capabilities, the options provided by the BMW Group’s in-house Additive Manufacturing Campus (AMC) can also be deployed. This provides the team with access to not only the advisory 3D printing experts, but also to a comprehensive range of printing methods and various materials for different applications.

Manufacturing of the components can be triggered directly from the track, via BMW’s own systems. Examples of parts that are printed in plastics or metals directly for use on the World Superbike include brake ventilation ducts in plastics reinforced with carbon fiber, complex molded parts, titanium crash pads, aluminum distributor boxes and aerodynamic trim parts.