Sauber Technologies, the manufacturing arm of the Sauber F1 team, and additive manufacturing specialist EOS have signed a three-year technology partnership. The cooperation will initially focus on the constant optimization and manufacturing of aerodynamic parts for the F1 team alongside other end-use parts for race cars and production aids.

Markus Glasser, SVP, EMEA at EOS, commented, “We see AM applications in F1 for both prototyping and serial production where reproducible part quality is key. Together with Sauber we are aiming to set new benchmarks here. With more serial AM applications in F1, automation will be essential too, enabling higher productivity and reduced costs per part. Sauber is the first customer for polymer-based AM, integrating this into its production, including the installation of an EOS P 500 system.”

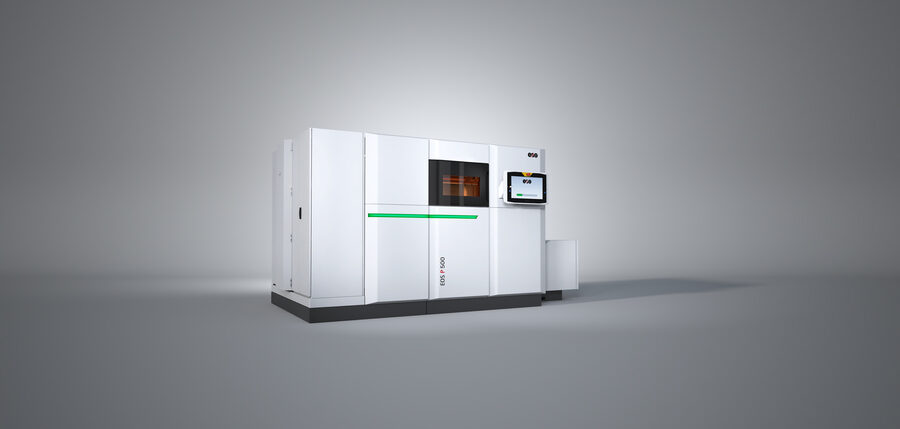

Sauber will be installing an EOS P 500 system in 2022, enabling the company to scale up applications toward serial production in the future, with an option to include automation solutions. Sauber will initially use the Polyamide 12 PA 2200 material.

The machine has a build rate twice as fast as the fastest laser-sintering system currently available in the polymer sector (EOS P 396). It has two powerful 70W lasers for precise energy input into the powder during material melting. Unlike previous EOS systems, the EOS P 500 brings the material to optimum processing temperature before application, thus shortening the time required for recoating and exposure.

Preheating and cooling of the interchangeable frame (with the 3D printed part) after production can take place outside the machine body. As such, a new production process can be started just 15 minutes after completing a build job. The system needs to be cleaned less frequently and serviced only once a year, so the uptime of the EOS P 500 is stated to be up to 75% higher, compared with predecessor systems.

Christoph Hansen, COO Sauber Technologies, said, “EOS and Sauber share the same passion for application-driven design and the highest quality standards, which we want to offer in motorsports and beyond. EOS’s company culture is a perfect fit for us, which is why we decided to enter this partnership. From a technology perspective, we co-operate with EOS because its ecosystem of partners and sister companies not only enables the end-to-end solutions we need, including automation, but provides us with highly custom solutions via AMCM (additive manufacturing customized machines).”