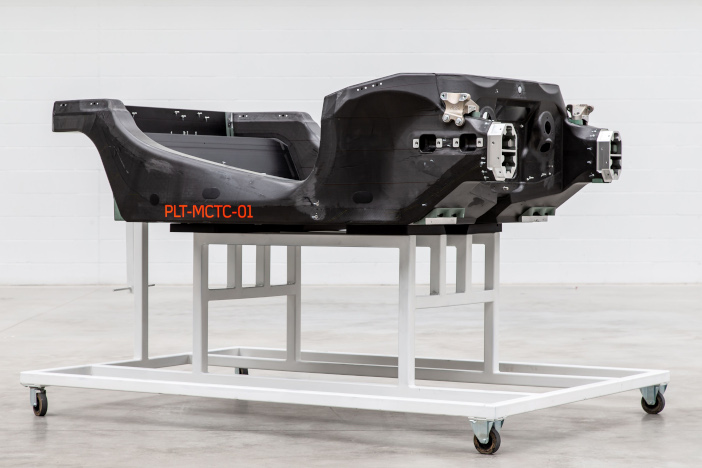

The first prototype lightweight carbon-fiber MonoCell, the tub that forms the main structure of McLaren’s cars, has been shipped from the company’s new £50m (US$65m) innovation and production center in Sheffield, UK, to the company’s Production Centre (MPC) in Woking, Surrey.

The prototype lightweight tub, McLaren Composites Technology Centre – 01 (PLT-MCTC – 01) completed its 175-mile journey to the British sports cars and supercar maker’s global headquarters from the McLaren Composites Technology Centre (MCTC), where it will be used in crash testing.

The lighter weight MonoCell is part of McLaren’s plans to achieve weight savings for its next generation of vehicles. The company expects reducing the weight of cars to become more important as they move toward hybrid powertrains, which are generally heavier than their traditional petrol counterparts. The company has said all of its sports cars and supercars will be hybrid by 2024.

The MCTC opened last year and employs around 60 people, which will rise to over 200 when full production commences in 2020.

McLaren’s first introduced carbon fiber to Formula 1 in the early 1980s and hasn’t produced a road car without it since.

Wes Jacklin, plant director of the MCTC for McLaren Automotive, said, “The delivery of the first prototype carbon fiber tub by the new MCTC to McLaren HQ is a significant milestone for McLaren Automotive’s ambition to be world-beaters in lightweight and composites technology, which goes hand-in-hand with our move to hybrid powertrains as part of our Track25 business plan.

“We never innovate for the sake of it; we innovate to continually fulfill our promise to create iconic sports cars. It’s increasingly clear that with future heavier powertrain requirements, exploiting innovative lightweighting techniques and technologies is going to be a significant key to unlocking all the handling and agility characteristics that our customers demand.”