Motorsport and automotive engineering firm HWA has shared in-depth details of its upcoming Evo – a modern reincarnation of the revered Mercedes-Benz 190E 2.5-16 Evo II performance saloon.

Limited to just 100 examples, the vehicle aims to offer a “contemporary, ultra-focused driving experience” using the latest technology and the most advanced design, engineering and manufacturing techniques.

“The HWA Evo is far more than just a ‘restomod’. In order to fully realize our vision for the car we are going to unparalleled lengths in terms of design, engineering and suppliers,” said Gordian von Schöning, CTO of HWA.

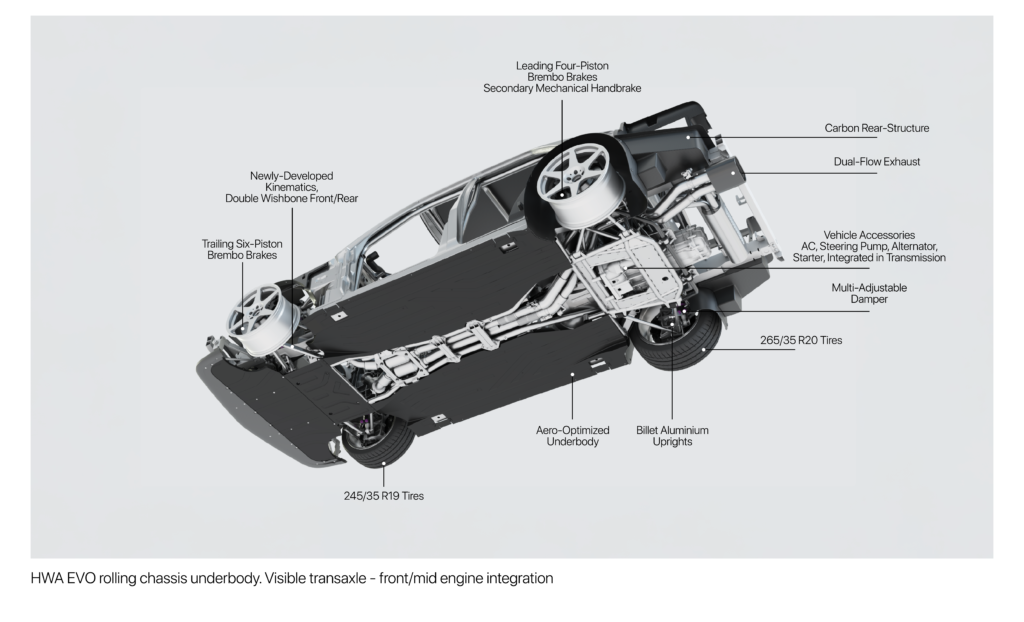

Each Evo build begins with a hand-selected Mercedes-Benz W201 donor car, which is stripped back to its steel chassis before being inspected and prepared to HWA’s strict quality criteria. Then, the front and rear portions of the donor chassis are removed and replaced with motorsport-grade aluminum and high-strength steel subframes, designed in-house by HWA. This ensures contemporary impact performance and advanced safety while also enabling the suspension to be mounted to the new chassis, resulting in a rigid platform.

The chassis is then further modified to enable the 3.0-liter bi-turbo V6 engine to be mounted as low and as far back as possible. The front axle is pushed forward by 50mm, ancillary components are repositioned, and the 6-speed manual transmission is relocated to the rear. This front-mid-engined, transaxle layout enables a targeted 50:50 weight distribution for “motorsport-derived” handling characteristics.

The retained steel midsection – including the A, B and C pillars – is extensively reinforced, ensuring that energy is channeled effectively through the new, rigid structure. In contrast to the original W201 donor, the HWA Evo now boasts more than double the torsional stiffness. Approximately 75% of the original car is replaced, before the full chassis is electro- or KTL-coated (Kathodische Tauchlackierung) for corrosion protection.

With the chassis prepped, engineers then assemble the additional components that contribute to the HWA Evo’s performance, including DTM-derived wishbones, billet-machined wheel carriers and various suspension parts.

Two brake options, steel and carbon ceramic, are supplied by Brembo, minimizing rotating mass and unsprung weight, and custom designed dampers are supplied by KW (manually or electronically adjustable depending on specification). The kinematic nature of the suspension also enables camber optimization under intense driving conditions, with stability strengthened by anti-roll bars from H&R.

HWA is also working with Bosch to develop its own ESP system, incorporating ABS activation, as well as creating a bespoke ECU for the Evo. “It is unheard of for a bespoke, low-volume manufacturer like HWA to partner with a top-tier OEM supplier like Bosch for such a limited production run,” said von Schöning.

At the end of the process, a full carbon bodywork is fitted to the re-engineered chassis and frame. The bespoke moldings not only include individual sections such as the doors and roof, but single structures which encapsulate the entire front and rear ends of the vehicle. Manufacturing these is highly challenging but enables the bodywork to take on a structural element, which contributes to exceptional rigidity and a light kerb weight.

HWA says that nearly all 100 examples of this homage to an iconic super saloon have already been reserved.