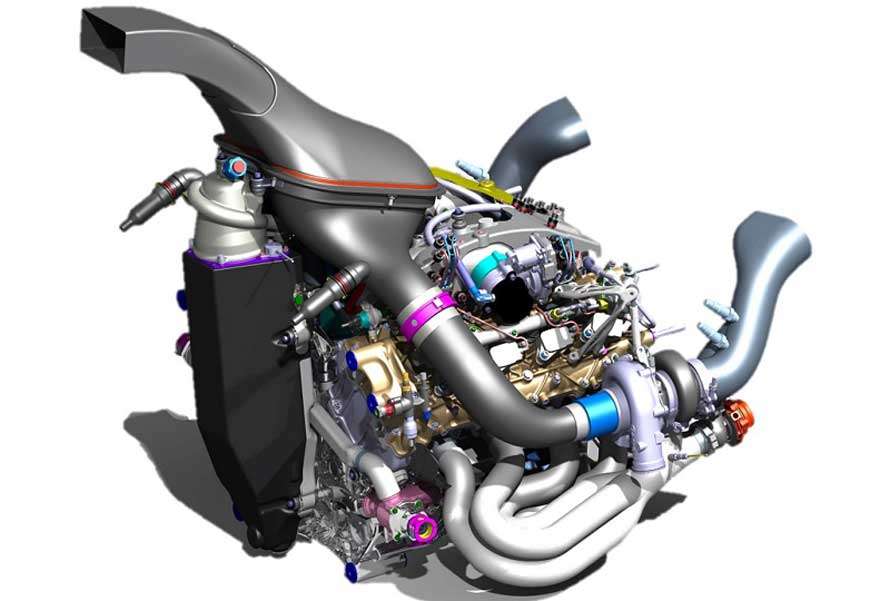

BMW has detailed some of the development work that has been underway with its M Hybrid V8, which will compete in the IMSA GTP class from 2023. Powered by the P66/3 eight-cylinder turbo engine with a spec hybrid system supplied by Williams Advanced Engineering, Bosch and Xtrac, the combustion engine is based on the DTM unit used in the M4 DTM in 2017 and 2018, redeveloped to incorporate turbocharging.

Even before the official start of the project, Ulrich Schulz, head of drivetrain design at BMW M Motorsport, and his group initiated an evaluation to determine which race engine would be best suited for conversion into a high-performance hybrid powertrain. Time and cost constraints meant that a clean sheet engine was not an option. Consequently, the question was to establish which existing, and proven, race engine would best meet the requirements and of the LMDh regulations.

The naturally aspirated P66/1 eight-cylinder engine was the logical choice. As it was already designed as a stressed unit, it could be reused in the LMDh chassis without an additional subframe and also suite the regulatory intent of the rules.

“During the evaluation phase, we also took a look at the P48 four-cylinder turbo engine from the BMW M4 DTM and the P63 eight-cylinder turbo engine from the BMW M8 GTE, but potential problems with the durability of the P48 and the heavy weight of the P63 were negative considerations,” noted Schulz.

“It is a huge plus that we were able to make use of existing materials such as steel and aluminum from BMW’s time in Formula 1 for the basis of the engine, as well as for individual components – like shafts, housing and small parts. That saved us time and a lot of money and was therefore efficient and sustainable,” he continued.

“Efficiency is a critical factor for this project, as we have a very short period of time available between getting started and the first racing appearance at Daytona in 2023. Converting the normally aspirated P66/1 engine into a bi-turbo and then working with the electric drivetrain colleagues to turn it into a hybrid drive system was very complex. Thanks to the expertise, the great collaboration and the high level of motivation of all departments, we managed to complete the fire-up of the complete drive unit just a few weeks ago. We now feel that nothing is standing in the way of testing.”

“Efficiency is a critical factor for this project, as we have a very short period of time available between getting started and the first racing appearance at Daytona in 2023. Converting the normally aspirated P66/1 engine into a bi-turbo and then working with the electric drivetrain colleagues to turn it into a hybrid drive system was very complex. Thanks to the expertise, the great collaboration and the high level of motivation of all departments, we managed to complete the fire-up of the complete drive unit just a few weeks ago. We now feel that nothing is standing in the way of testing.”

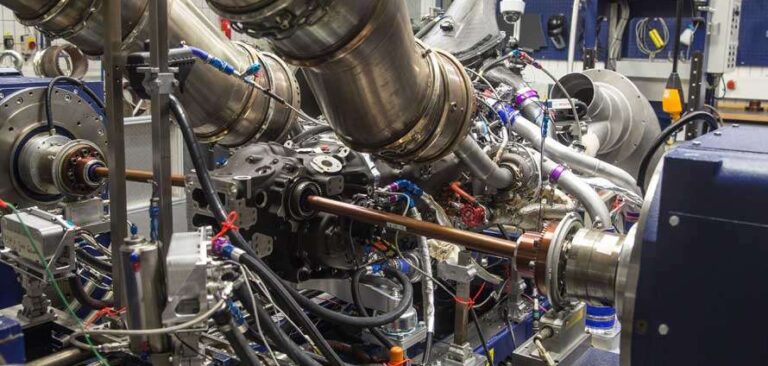

The first phase of development saw the normally aspirated P66/1 DTM engine converted into an intermediate engine, named P66/2, primarily by adapting two turbochargers and adjusting the crank drive. The focus was on durability, increased performance and temperature management for the engine. The P66/2 completed numerous testing units, including complete racetrack simulations, on the test bench.

The next step was the creation of the P66/3 race engine with adjustments to meet the specific requirements of the Dallara chassis, design of the final exhaust system, oil tank, cabling and integration of the high-voltage environment. The cylinder block and cylinder heads were recast at the BMW Group foundry in Landshut and the injection system was redesigned for direct injection.

| Capacity | 3,999cc |

| No. cylinders | 8 |

| Cylinder construction | Cast aluminum cylinder block and cylinder head, cylinder lining as iron layer in LDS procedure |

| V angle | 90° |

| Bore | 93mm |

| Stroke | 73.6mm |

| Cylinder spacing | 102mm |

| Valves per cylinder | 4 |

| Engine speed | max. 8,200rpm |

| Output (regulated) | approx. 640hp |

| Torque | approx. 650Nm |

| Injection | High-pressure direct injection at 350 bar |

| Oil system | Dry sump system with six-cell oil drain pump and oil tank |