Hypercar manufacturer Koenigsegg has released details of its Quark electric motor, which utilizes what the company says is a novel torque/power-rich balance between radial (power-dense) and axial (torque-dense) flux topology, dubbed Raxial Flux. Furthermore, Koenigsegg has integrated two Quark e-motors with one of its David six-phase inverters, plus planetary gearsets, to create the Terrier, a torque vectoring EV drive unit.

Koenigsegg says that the Quark e-motor goes back to the first principles of magnetism, materials, cooling and packaging. The mixing of radial and axial flux layouts enables what the company claims to be the best torque-to-power-to-weight ratio in the industry.

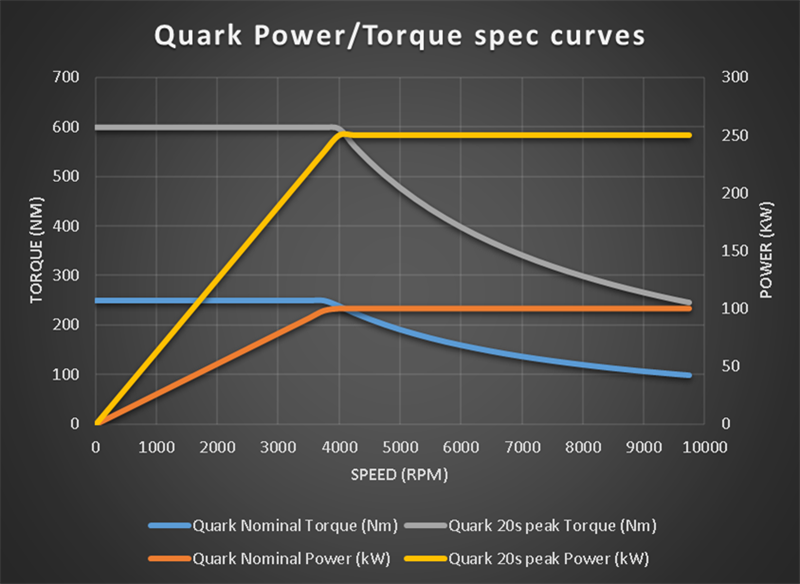

András Székely, Koenigsegg’s e-motor development lead, explained that reducing weight and both electrical and mechanical losses were key targets in the motor’s design. “We constructed the shaft within the Quark out of 300M steel used in motorsports and aerospace. Direct cooling was chosen for its higher cooling efficiency and compact design. Even the rotor uses the renowned Koenigsegg Aircore hollow carbon-fiber technology (also used in Koenigsegg’s rims, steering wheels, seats, etc). We not only overcame the challenge of the Gemera’s powertrain requirements but also exceeded the goals of making it lighter and smaller than any electric motors in this class. The Quark presents new benchmarks in compact and torque-rich engineering with the first production version weighing just 30kg, producing up to 600Nm of torque and 250kW of power. Without the extra driveline functions for the Gemera, the Quark can drop below 28.5kg in weight.”

Two of the motors are used in the Terrier electric drive unit, coupled to a single six-phase inverter using three phases for each Quark. Thanks to the Quark’s flat packaging, similar to that of a traditional radial flux motor, the inverter can be slotted between two motors to create a very compact package. Thanks to the high power and torque output at relatively low speed, only a small planetary gear system is required to transfer drive to the wheels.

“The Quark is unique in its high efficiency in combination with its class-leading torque-to-power-to-rpm-to-weight matrix,” added company CEO and founder, Christian von Koenigsegg. “This means that when using the Quark in applications such as marine, aircraft or VTOL, there is no need for a step-down transmission; instead, direct drive can be achieved as the RPM of the motor is right from the get-go. Small high-revving motors can have higher peak power-to-weight ratio but they need transmissions in most applications in order to get to the desired output RPM and torque, causing energy loss and adding weight and complexity to do the same job. So any benefit in size is lost. In other cases, like the Terrier application, the transmissions can be reduced in size and complexity compared to higher-revving, less torque-dense motors, which is also a big win. I guess we’re trying to reach the edge of optimal in-betweenness.”