The 2022 Formula 1 season has finally begun, bringing with it the most significant shakeup in aerodynamic regulations in a generation. Professional Motorsport World will be providing coverage from pre-season testing in Barcelona, with technical imagery and insights from teams’ engineers, giving a comprehensive overview of how this new era has driven car design and the different approaches taken across the grid.

The links below lead to galleries and technical content on each car. Click the + symbol to expand content.

- Red Bull RB 18

- Mercedes W13

- Ferrari F1-75

- McLaren MCL36

- Aston Martin AMR22

- Alpine A552

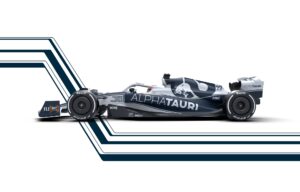

- AlphaTauri AT-03

- Williams FW44

- Alfa Romeo C42

- Haas VF-22

Click the back ‘Back to car menu’ link to return to this list at anytime

Particular thanks goes to Kyle Forster, of JFK Aero, which provides aerodynamic and mechanical consultancy services, for permitting the use of his excellent analysis videos.

[accordions]

[accordion title=”2022 technical regulations explained” load=”hide”]Mercedes produced an excellent series of videos setting the stage for 2022, detailing both the development of the rules and their impact on the design of its car, which can be viewed here.

The 2022 technical regulations can be downloaded here.

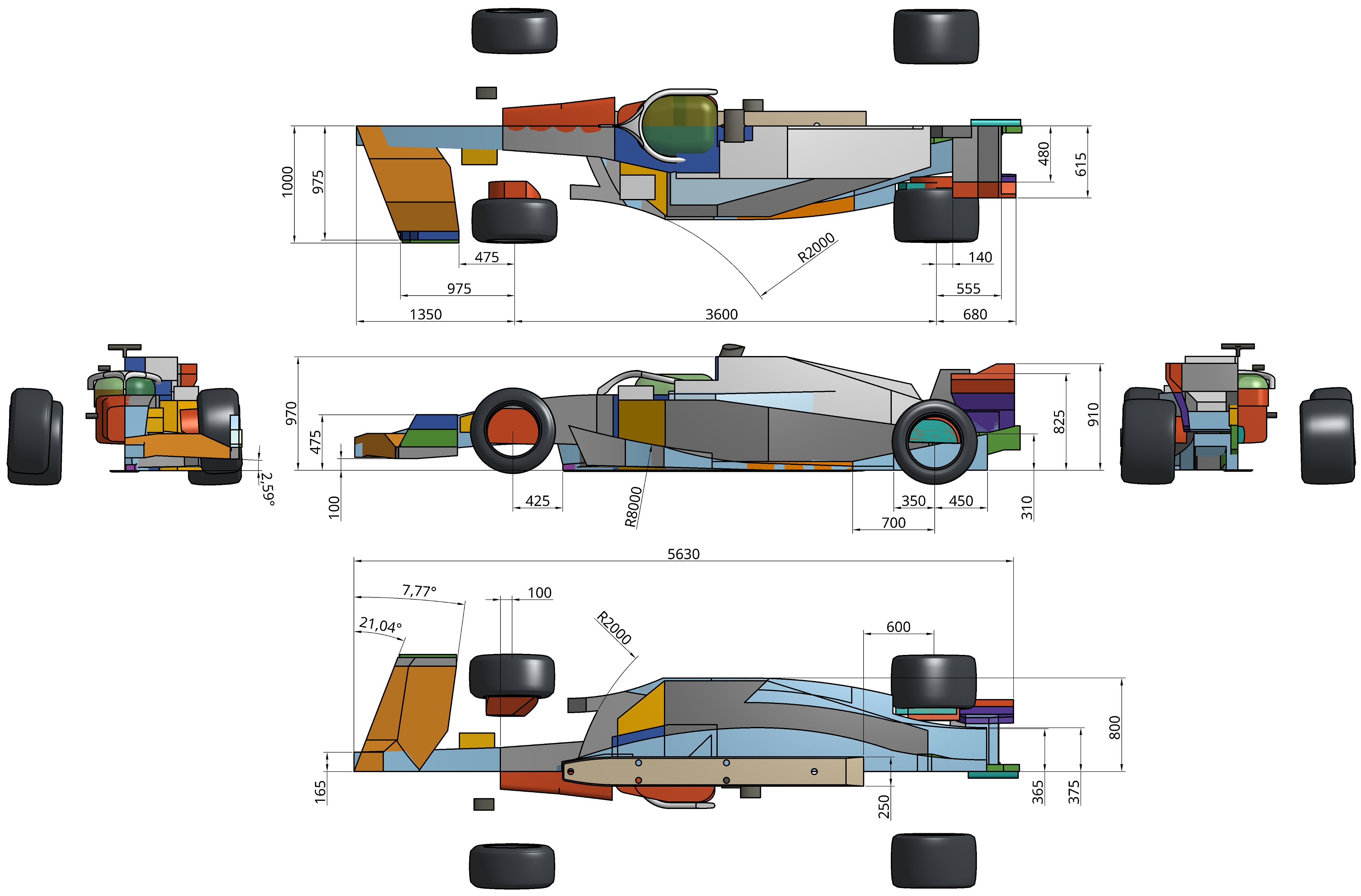

The regulations see a complete revamp of the aerodynamic rules dictating the form of the cars, created with the intent of improving overtaking by reducing the loss of downforce for following cars. In simple terms, this has seen a shift to a greater reliance on the underfloor for downforce generation rather than the front and rear wings, front floor area and diffuser, with the cars now featuring full-length tunnels to make greater use of ground effect, and which are less susceptible to dirty air.

At the same time, bodywork design has been constrained to prevent teams taking measures to push the dirty air from the tires out to the sides of the car. For example, the design of the front wings has been greatly simplified; they are now limited to just four elements, while the end plate design is tightly regulated. Similarly, the front brake ducts, previously an area of extensive development, are now closely controlled as are any features intended to force air out through the wheels (a tool previously used to drive the wake out to the sides of a car). Complex features such as bargeboards are now also consigned to the history books.

These constraints are achieved thanks to a new approach to defining the geometry of the car’s bodywork. Whereas previously, engineers had near-total freedom within a set of dimensions that defined a series of square or rectangular boundary boxes, now these boundary boxes are much more complex geometric shapes, as illustrated below.

Regulation boxes for bodywork, courtesy of Josh@AeroGandalf

F1 undertook a considerable in-house research program to simulate the previous generation of cars and iterate the new rules, leveraging the impressive cloud computing power of its technical partner, Amazon Web Services, as described by Rob Smedley, head of data systems at F1, below. The result of these sweeping changes, F1 hopes, is that greater downforce will be maintained as a car closes in on one in front and thus closer racing will ensue.

When asked if the 2022 regulations truly presented an opportunity to shake up the order, AlphaTauri team principal Franz Tost cautioned prior to testing, “It’s difficult to answer right now, because the completely new technical regulations mean that all the teams have had to design this new generation of car from zero, from a blank piece of paper. Although everything is quite restricted by the regulations, it’s possible that one team has found a very special solution and will therefore have a performance advantage.”

[/accordion]

[/accordions]

[accordions]

[accordion title=”Cost cap overview” load=”hide”]Also playing a significant role in 2022 is a cost cap that now dictates teams’ spending.

Alongside the revised technical regulations for 2022, Formula 1’s cost cap is now in full swing, limiting teams’ budgets in the name of improving parity across the field. The cap was originally introduced in 2021 and set at US$145m, which had to cover all operations with some exceptions, including power units, marketing, hospitality, team travel and driver salaries. The salaries of the top three personnel are also excluded. For 2022, the budget was cut by US$5m to US$145m, with a further US$5m reduction due in 2023.

The cost cap was initially set at US$175m, with a gentle ramp-down to the current level to give bigger teams time to restructure and reduce potential job losses. However, the untimely arrival of Covid saw this figure slashed by US$30m and a considerably more abrupt reduction in resources available to the likes of Mercedes, Ferrari and Red Bull. Though US$145m is a far from paltry sum, it has caused teams to cut back in certain areas. Mercedes, for example, had to forgo wet tire testing on the new 18in rubber ahead of 2022, as it would have eaten too much budget (particularly bearing in mind the US$1m devoured by Valtteri Bottas’s sizable crash at Imola last year).

It is a fallacy that money is no object even in the largest outfits, and every team already had methods in place to assess the development potential of upgrades against their costs. The cost cap means these have to be honed to a higher degree, and greater efficiencies found in all areas of operation. As Alpine technical director Matt Harmand outlined. ” It’s making sure that we’re operating efficiently together, making sure that we are taking good engineering decisions, and getting things more often than not right first time, because it is important that, in essence, our efficiencies incredibly high, because out of that will come great performance.”

It is also the case that switching car concepts in 2022 will be a tricky task due to the inherent costs of reengineering an entire vehicle.

“I think that the cost cap will have an effect because this year it’s been brought down by a further five million,” said AlphaTauri team principal Franz Tost at the launch of the team’s AT-03. “It should make a difference, but as the big teams were able to benefit from a larger number of people until summer last year, they of course had an advantage. They were able to do a lot more research and development work, especially using simulation tools, and could try several different design philosophies to find the best solution for them. Therefore, it could be the case that the top teams will still have an advantage, but the gap between the top teams and the rest of the field should be smaller and all of the cars are expected to be much closer together.”[/accordion]

[/accordions]

[accordions]

[accordion title=”Rob Smedley on how Amazon made F1 2022 a reality” load=”hide”]

Since 2019, Formula 1 has had a partnership with Amazon Web Services, giving it access to the Silicon Valley giant’s impressive array of cloud computing resources. The organization has leveraged this in a number of ways, such as race prediction information displayed on television feeds right through to the development of the 2022 rule set (in conjunction with the FIA).

Professional Motorsport World speaks to Rob Smedley, former director of data systems at F1 and now a consulting engineer to the organization, to find out how the partnership gave F1 the capabilities to devise the most significant rules shake-up in a generation.

The starting point for the new formula was ascertaining which elements of the previous car package were most detrimental to achieving closer racing. “If you go right back to the crux of why we have done the 2022 car, it all stems from what the customer wants. That customer is our fan base, and the fan base was fairly clear in requesting that they wanted closer racing. They wanted more wheel-to-wheel action,” says Smedley. “They want to see more close racing, which does not necessarily mean overtakes. Overtaking is the cherry on the cake, if you like. We set about trying to understand how to do that.”

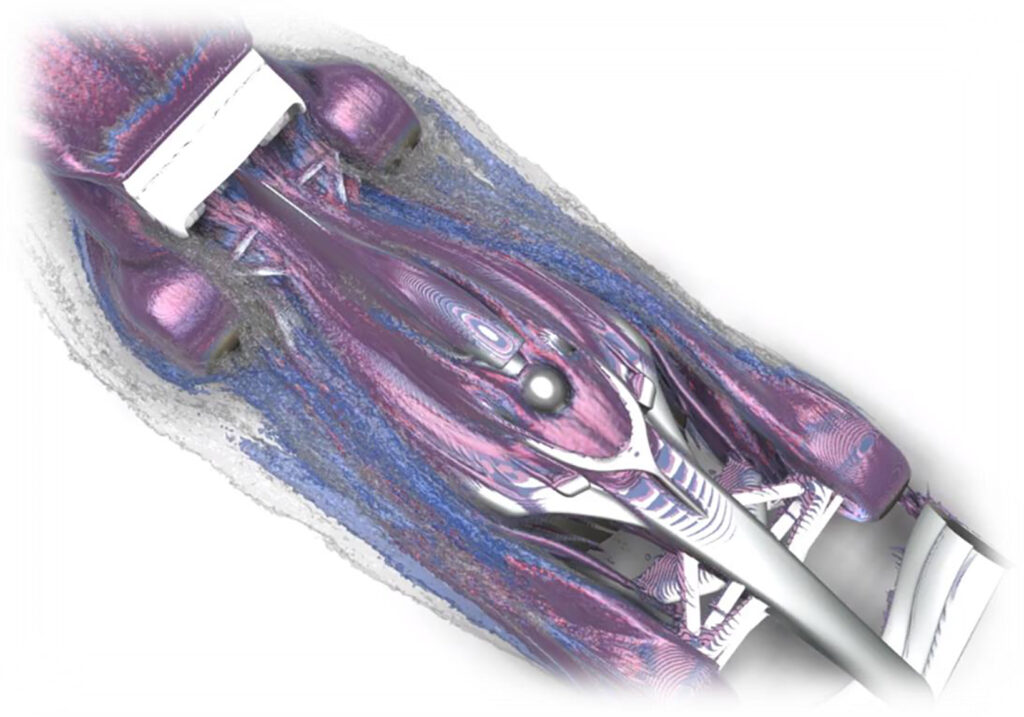

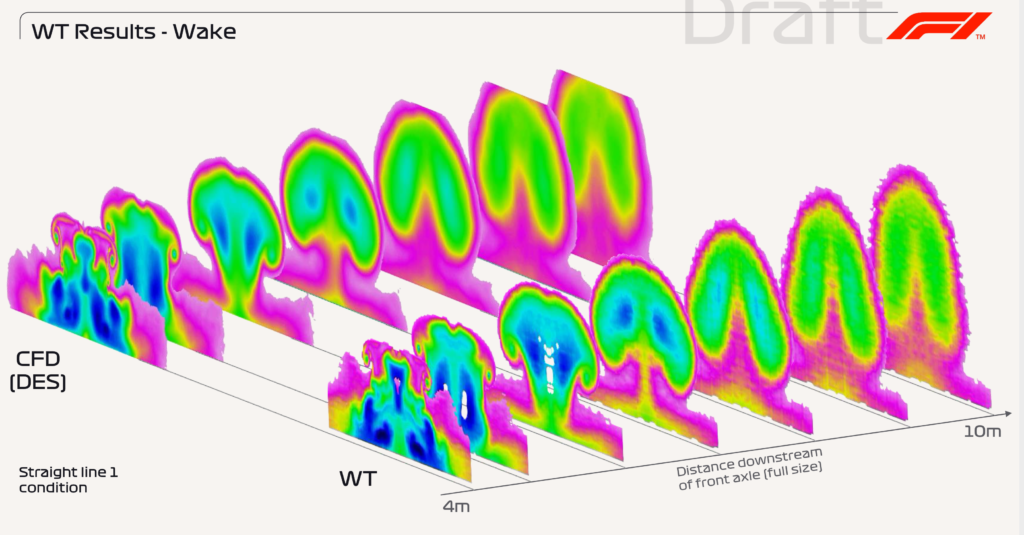

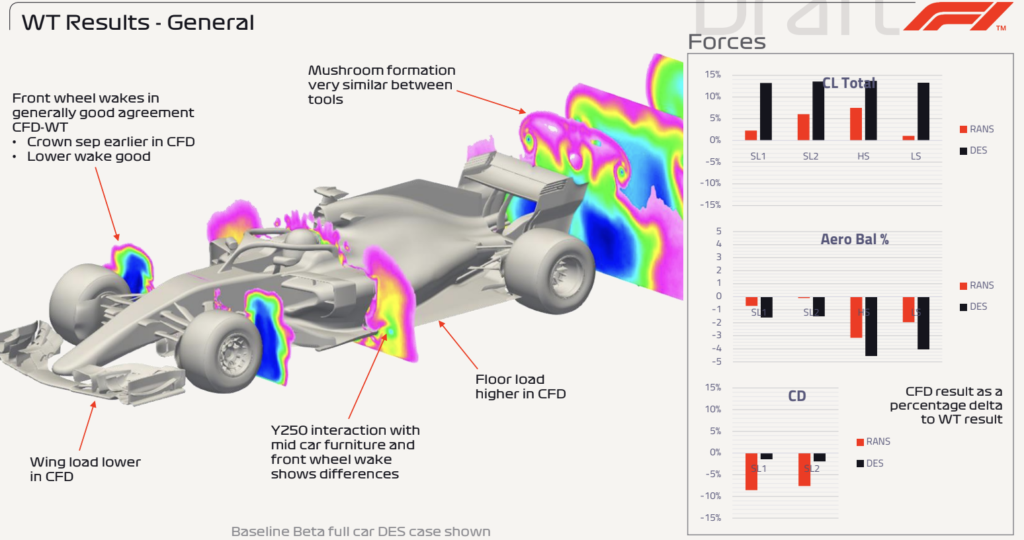

The process began by conducting an in-depth analysis of the aerodynamic behavior of the then-current cars when following each other. Starting in 2017 with an in-house team – including Pat Symonds, formerly of Benetton, Renault and Williams, and Nicholas Tombazis, formerly of Ferrari – F1 set out to make sure the regulations were not just guesswork. Key to this was its acquisition of the wind tunnel model and CAD data for the Manor F1 team’s unraced 2017 car, which formed the basis for its research. Using these as a baseline, testing was undertaken in the Sauber wind tunnel in addition to CFD analysis to establish a reliable wake profile for the cars.

“We knew that turbulent flow structure that comes off the car in front is very detrimental for the car behind, and we started to look into this in much more detail,” explains Smedley. “Our studies showed that when you get to, say, within half a second of the car in front, you start to really struggle with the turbulent air and lose in the region of 40% of the downforce.”

“We knew that turbulent flow structure that comes off the car in front is very detrimental for the car behind, and we started to look into this in much more detail,” explains Smedley. “Our studies showed that when you get to, say, within half a second of the car in front, you start to really struggle with the turbulent air and lose in the region of 40% of the downforce.”

With this baseline established, F1 then set out to design a car that suffered less when following another car while also having a reduced wake. “That is where the first technology problem came in. Because what we did was, for the first time ever – well, not the first time ever, but the first time ever at scale – was develop a two-car model,” recalls Smedley.

Bring out the big guns

Bring out the big guns

A high-fidelity, two-car model requires a phenomenal level of computing power to solve in CFD. Smedley notes that using the resources permitted to teams under the current rules, each simulation run would take 40 hours to complete. Even though F1 was using the UK’s Archer supercomputer, Smedley admits, “That was in no way agile enough to be able to actually get through the amount of design work that we needed to get through.”

So it was that F1 approached Amazon as a technology partner and began to utilize its cloud computing resources. “We built a substructure within EC2 [Amazon’s Elastic Compute Cloud infrastructure] so that all of the calculations ran in the cloud,” says Smedley. “Doing that, we quadrupled the number of cores we were using as a baseline. That cut the runtime down from 40 hours to around seven.” The upshot was that the aerodynamicists working on the project could work through many more design iterations, as well as run concurrent simulation runs.

For Smedley, the computing firepower brought to bear was on a higher level than anything he had experienced before: “It’s mind-blowing, the amount of power that we could call upon. At one point we had something like 14 concurrent jobs, running on 7,000 cores, with 2.4 billion cells of Navier-Stokes equations, all calculating concurrently!”

Working with the teams, who were permitted to undertake studies on particular areas of the 2022 rules outside of the rules-based restrictions, F1 went through a variety of vehicle design iterations until eventually settling on a basis for the new technical regulations, which were then codified into the FIA’s rules.

Working with the teams, who were permitted to undertake studies on particular areas of the 2022 rules outside of the rules-based restrictions, F1 went through a variety of vehicle design iterations until eventually settling on a basis for the new technical regulations, which were then codified into the FIA’s rules.

Keeping track

However, though the 2022 rules represent a phenomenal body of work by both F1 and the FIA, Smedley knows that teams have little interest in their spirit and will be focused purely on performance. Some of the development paths they take could well reduce the rules’ effectiveness in terms of close competition.

Here, the power of AWS will once again come to the fore, with F1 able to conduct extensive analysis of the huge amounts of data it harvests over a race weekend, harnessing AWS’s AI-driven tools to spot patterns and trends.

Smedley says, “That will give us a lot of insight as to how the teams develop. What is their rate of development? What areas are they developing? It will let us see how the 2022 car evolves once we give it to the teams. That insight will then allow us to help the FIA tweak the regulations going forward.”

Looking even further down the line, Smedley says F1 is also working on developing a proof of concept for generative design development, which could be used to help refine the next major rule set in a resource-efficient manner, in addition to making much greater use of AI-driven data analytics across the board.

[/accordion]

[/accordions]

Red Bull: RB18

Team principal: Christian Horner

CTO: Adrian Newey

Technical director: Pierre Wache

Technical director – powertrain: Ben Hodgkinson

Chief engineer: Paul Monaghan

Power unit supplier: Red Bull (Honda)

[accordions]

[accordion title=”RB18 in detail” load=”hide”]The car Red Bull unveiled at its official launch was nothing more than a slightly tweaked version of the F1 2022 showcar, with the real RB18 not making an appearance until testing began in Barcelona.[/accordion]

[/accordions]

[accordions]

[accordion title=”Key suppliers” load=”hide”]

Fuel and lubricant: Mobil1

Coolers: PWR

Safety equipment: Sabelt

HPC systems: Hewlett Packard

Metrology: Hexagon

Simulation: Ansys

Machine tools: DMG Mori

[/accordion]

[/accordions]

Mercedes: W13

Team principal: Toto Wolff

CTO: James Allison

Technical director: Mike Elliott

Managing director – powertrain: Hywel Thomas

Power unit supplier: Mercedes AMG HPP

[accordions]

[accordion title=”W13 in detail” load=”hide”]

As the second F1 pre-season test session got underway in Bahrain, Mercedes caused something of a stir with a radical take on the sidepod design of its W13.

Sidepods are one of the most visually differing areas of the 2022 specification cars from team to team, reflecting the various approaches to aerodynamic concepts across the grid. In the case of Mercedes, its design appears to be a particularly creative interpretation of what constitutes the ‘sidepod’.

There are three key features that standout in the design: the encapsulation of the upper side impact crash structure in a sculpted shroud, the use of a tall, narrow cooling inlet, set low down on the car, and an outer sidepod edge that flares out to the floor, rather than being undercut.

As aerodynamicist Kyle Forster explains in the video below, the crash structure layout (and its attached mirror) takes advantage of very specific wording in the rules relating to how elements such as the mirror support are defined as well as the volumes dictating the geometry of the sidepod when sectioned on different planes. The same applies to the outward flaring shape of the sidepod.

[/accordion]

[/accordions]

[accordions]

[accordion title=”Q&A with Mike Elliott” load=”hide”]

Mike Elliott is the technical director of the Mercedes-AMG Petronas Formula One Team.

Just how significant are the rule changes for 2022 and how do they compare to previous regulation changes?

On the chassis side, the changes are huge. We haven’t had a change as big as this one in my career. I think there are three aspects to this: first, the way the regulations are constructed is very different, particularly for aerodynamics, and that has a big impact. Second, what they are trying to achieve with the aerodynamics means the cars are fundamentally a different shape. Third, this is the first time we will have attempted such a big change under a cost cap.

What was the feeling within the team, taking on this challenge?

Engineers love a challenge and therefore it is a fantastic opportunity to do something fresh. In the aerodynamics world, normally you are chasing after little bits and pieces, but with such big regulation changes, the gains have been coming in big chunks, which is satisfying. On the flip side, we’ve had a period of success, winning the last eight Constructors’ titles and this is a reset. All the teams have started from scratch with the model provided by F1. You don’t get to carry over the benefits or fix the issues from last year’s car, so everyone began this journey at the same level. But importantly, the teams have also started with different allocations of runs in the wind tunnel and CFD, so it has the potential to really mix up the order. That’s an exciting test as an engineer but there is obviously some risk in there too, in terms of our competitive position.

In which areas will the car be most affected by the technical changes?

The aerodynamic changes are significant, and certain components, like the gearbox, are now locked in place until 2026. The power unit is another: the performance specification will be frozen until the new power unit is introduced in 2026. They have big impacts because you want and need to get them right, to make sure they see you through the next few years.

The aerodynamic changes are so big, they completely influence the packaging of the car and where you want to put certain components. Compared with last year, we’ve basically only carried over the steering wheel; otherwise, it’s all new, and that’s primarily a consequence of these new aerodynamic rules. The way the aerodynamic surfaces are defined in the regulations is also completely different: this year you are given a CAD surface and a tolerance to it. That means the designers must think differently and the process of making sure the geometry is legal is much harder. In the past, we had lots of little details on the car that added up to quite a big chunk of aerodynamic performance, but now, the component detail isn’t anywhere near as complex. So, the gains you are making are in fundamental shape changes and bigger components than before.

Have there been any particular areas you’ve focused on with the W13? What has been the main focus with the 2022 car?

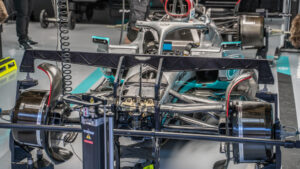

We have talked a lot about the aerodynamic changes because these are most visible, and these regulations aim to improve overtaking. In fact, most of the car has had to change, which has been a huge challenge for the whole team. Getting to the desired aero shapes has meant a complete internal repackaging, right down to the electrical layout and where we fit things like the ECU. The suspension has been redesigned to account for the loss of hydraulics and remote springs, now banned in the new regulations. Hopefully, you will also see that we have taken another step with how tightly packaged the sidepods and engine cover are. To get to this is not just a case of a shrink-wrapping exercise but requires a huge amount of redesign and simulation to make it work. In summary, it has been a massive job.

The tires and wheel sizes have changed for 2022. What does this mean for the car in terms of handling and performance?

We have moved to an 18in rim and new tires to go with it. They are lower profile as a result but not so low a profile that it fundamentally changes how the tires work. What we have seen in testing, particularly the Abu Dhabi test at the end of 2021, is that there are subtle differences. It is going to change what we want to do with setup, but it is a step in the right direction as I think the tire will help improve the racing, won’t overheat as much and will be easier to manage.

What’s been your overall approach to these new regulations? What have been the key milestones for you to reach?

We started development of what has become the W13 in 2020, with early work on the aerodynamics and the major components such as the gearbox, chassis and power unit. When Covid struck, it was clear we were not going to switch to this new regulation set for 2021, so we had to change the focus onto adapting to the changes for 2021; but as the regulations settled down, we moved more and more focus to our 2022 car. That was a tough balance to find because we were fighting at the front last year, but the development rate of the 2022 car was much stronger.

We started with the bigger components earlier than we normally would and it was the same with the aerodynamic programme in CFD and the wind tunnel: you gradually try and learn what you want to do with the car, what directions you want to take, building up performance and working through your milestones. As you get further through the process, it then becomes about signoffs, homologation work and tests. For example, this year the chassis faces a 300kN squeeze test, which is a massive load. It’s a challenge to get through those homologations on the chassis, and we did that.

Then it’s about the marriage between the chassis and the power unit, putting them through the virtual track testing on the dyno before moving on to getting everything ready and built for testing so the car can hit the track for those initial system checks and tests. As you progress through winter testing, the focus is on building up a base understanding of the car performance, where the gremlins are, the learning opportunities and reliability issues to get on top of, building your way toward the final package you take to race one.

Is testing even more important this year, given it signals the start of F1’s new era?

With the limited testing, it’s always important to extract maximum learning from those precious few days, which you can then take forward and use throughout the season. The fact the cars are so different means the amount of learning is far larger and therefore there is more to gain from testing than there ever has been before. It helps we are running in both Barcelona and Bahrain, because Barcelona is traditionally a reference circuit with a good mix of corners, so you can get a good idea of where the car is at, while in Bahrain you are almost guaranteed dry running.

Is the vibe any different ahead of car launch, testing and the new season, considering you’ve had to start from scratch with W13?

Yes, it is, and for several reasons. In a normal year, I think you can probably have a good estimate of the development slope and therefore what ‘good’ is likely to look like. You can’t do that this year, and the changes are so huge that no one will know exactly what they are aiming for. You’ve also got the fact that the vast majority of the car’s components have changed, and having to do that in a cost cap world means the factory is stretched more than it has probably ever been. But everyone is doing a good job of dealing with that pressure and maximizing the output so we can bring every bit of goodness we can.

What can the fans expect from this new era of F1?

What they can expect is something different. The question is, what does different mean? I think it’s impossible for any of us to say if this will close the grid up. Are there going to be loopholes found in the regulations that mean there will be a surprise team at the front? Until we get to the track, it is difficult to say. The rules were constructed in a direction to improve all of that, but it is the team’s job to make the fastest car we can. All these unknowns ahead of testing and the first race are exciting because no one knows what’s going to happen or how it will play out. It’s a challenge we’re relishing and have enjoyed getting stuck into, but we’ll only find out how good we are when the flag drops in Bahrain.

So now the W13 is hitting the track for the first time and being revealed to the world, how are you feeling about the new car, Mike?

It is always a special moment when you see the car run for the first time. It sounds like a cliché, but people have sweated blood and tears in Brackley and Brixworth, through the year but particularly over the build period and winter, to deliver the car and be able to run it. Now we enter the learning phase. Because the cars will evolve so much over the test, we won’t know where we are until we get to the first race, but we’ve got that mixture of trepidation, excitement of developing the car and seeing what we have created, and pride about what we have achieved together.

[/accordion]

[/accordions]

[accordions]

[accordion title=”Q&A with Hywel Thomas” load=”hide”]

Hywel Thomas is the managing director of Mercedes AMG High Performance Powertrains.

Hywel, a new season comes with a new power unit. Can you tell us more about the Mercedes-AMG F1 M13 E Performance?

Naturally, our 2022 PU builds on the generation of championship-winning power units that have been produced at Brixworth since the start of the regulation cycle in 2014. Each season, it’s about finding more performance, more reliability and taking the overall package of the power unit further. Plus, we have had an all-new chassis in which to install the PU, with all the challenges and opportunities that provides. For 2022, it has been a wide and deep project, and we have changed more parts of the PU for this year than in any season since 2014. Because it’s been such a significant change, we modified our overall approach to design and development; we started earlier and had more points along the journey, where we could experiment with some of our technologies. And it wasn’t a case of spreading the same amount of effort over a longer period, it was about having a very high level of activity over a longer period.

There’s a new power unit freeze regulation for 2022 but also beyond. What exactly does this mean?

2021 was the first season in this regulation cycle where we had to freeze the performance specification of the PU at the start of the season. In 2022 we’ve been allowed one final performance upgrade, most of which needs to be delivered at the start of the season, and the ERS system upgrade must be introduced before September 1. But this doesn’t only have an impact on 2022, because the performance specification will remain frozen until the start of the next regulation cycle in 2026. The project we took on for 2022 was large, and it is a very broad upgrade across the different elements, to get every last bit of performance, efficiency and reliability. There are also some FIA-imposed measurements, particularly in the ERS system, that we had to accommodate as well.

What opportunities have the new chassis regulations created from Brixworth’s perspective? Has this created challenges for the power unit?

It’s always an interesting project when there are such significant changes to the chassis regulations. The chassis team have been working very diligently and swiftly through the new regulations, so they can understand where the opportunities lie, and which areas are lap-time sensitive. We make changes to the PU that allow the chassis team to best exploit the regulations. We might want to rearrange the installation slightly or change the PU layout to get more flexibility in those lap-time-sensitive areas. The other side of this is we never really know how much performance, in terms of chassis performance, we are going to find. We have some very good simulation tools and of course we use those to make estimates of where the chassis will end up, but we don’t know for sure. And that means we won’t really know precisely how the PU will need to be used and the way it needs to react while out on track until we are running on the circuit. We have to cover quite a lot of possibilities to make sure that PU is ready for whatever turns up at the end of the experience.

How closely has Brixworth been working with the team in Brackley ahead of the 2022 season? What have been the key milestones for this collaboration?

When there is a big regulation change, it means the links between Brixworth and Brackley need to be stronger than ever, to make sure we are exploiting every area of the chassis and PU. I think the collaboration this year has been extremely strong and that’s vitally important, especially in a year where so much has changed. Naturally, we also work closely with our customer teams; the great thing about that is we have additional sets of very talented engineers looking at the regulations and seeing opportunities in the way the PU is installed in the chassis, the way the PU is laid out to help them work on the chassis. The collaboration with Brackley is at a different level, but the customer teams do have an important input, and this all helps make the PU better.

The new E10 fuel, 10% of which is made up of sustainable ethanol, debuts this year. What impact has that had on the preparations?

In some regions, people will be familiar with E10 fuel, as it has appeared in the pumps quite recently. We’ve got 10% ethanol in the fuel and it doesn’t necessarily sound like a big change, but it is quite a significant one in the way the fuel and the PU interact. So, it’s been a sizeable challenge, but I think it has been a good development phase for us. Working so closely with our partner, Petronas, that collaboration with them is vital. I know we’ve tested more candidates and gone through more development loops this year than we have for a number of years, and have found some interesting developments. It’s a second-generation sustainable ethanol, so a small but important step in the right direction in terms of sustainability.

Do you expect the performance and way the power unit operates to change in 2022 with the new rules and changes to the fuel?

I suspect the way the PU operates over a lap will not be the same as last year. While it’s difficult to really know the lap time difference, generally the car will perform differently, generating downforce and performance in a new way. The drivers will want the PU to do different things at different times through corners and potentially from one corner to the next, because of the car characteristics. The amount of full throttle time, the way the drivers approach and exit corners, won’t be exactly like they used to be and this will also have a knock-on to how we harvest energy and deploy it. We’re going to have to be reactive, to make sure we are delivering whatever the driver is requesting. Over the course of the year, given the regulation changes, I think the development of the overall car package will be quite strong, so the way the PU works at the start of the season won’t be the same come the final races of 2022. We must include that ability to be adaptable into the PU from the start of the season, because of the performance freeze. Because of these unknowns and the amount of change, testing and track time before the season begins really will be crucial. There are great simulation tools, getting us in the right area, but nothing can match bolting the PU into the back of the car and going around the circuit.

How excited have you been to grapple with the challenges of these 2022 regulations?

As we’ve gone through this cycle, there are obviously huge changes in regulations on the chassis side and on the PU side, and these all add up to opportunities and challenges for an enthusiastic engineering team such as the one that we’ve got in Brixworth. We love to analyze, consider and then do everything we can to deliver the best products. I think there is real excitement to see the PU and the car working together and see what happens when we hit the track. The big lap time and most obvious changes are on the chassis, but things like the E10 fuel, the freeze until 2026, those are some really, really important elements to get right. So that little bubble of apprehension is even larger than usual. Have we done enough? Have we left no stone unturned? That’s at the front of our minds, which is exciting and scary all at the same time. But that’s why we’re involved in F1.

And on car launch day, how are you feeling, personally, about the first shakedown of the W13?

I’ve been fortunate enough to go to a number of launch days over the years and it never stops being hugely exciting. For all of us who are so involved and invested, that is quite emotional, to see the chassis and PU go down the pit lane as one for the first time. To hear the engine, to sit back and reflect on all the components that are working in there together. All the people, the hard work, the effort. It’s always slightly mind-blowing, and it’s a lovely moment to message back to the factory, telling them the car has hit the track.

[/accordion]

[/accordions]

[accordions]

[accordion title=”Key suppliers” load=”hide”]

Fuel and lubricant: Petronas

Coolers: TBC

Safety equipment: TBC

HPC systems: TBC

Metrology: TBC

Simulation: TBC

Machine tools: TBC

[/accordion]

[/accordions]

Ferrari: F1-75

Managing director: Mattia Binotto

Head of chassis: Enrico Cardile

Head of powertrain: Enrico Gualtieri

Racing director: Laurent Mekies

Power unit supplier: Ferrari

[accordions]

[accordion title=”F1-75 in detail” load=”hide”]

Though very much a ‘launch spec’ car that was first unveiled to the public, it was clear Ferrari had chosen a different route to the rest of the field with the design of the F1-75. The most striking element of the car being the sidepod design, which rather than featuring a smooth upper surface, incorporated a large scalloped section. Ferrari has, understandably, not explained the reasons for this design, however, some very approximate CFD simulation has been conducted by a member of the F1 Technical Forum, using a modified 2022 base car model, which can be seen here. The simulation hinted that Ferrari’s approach could net a useful reduction in drag.

As Enrico Cardile, Ferrari’s head of chassis pointed out. “Aerodynamics was definitely our number one priority. We approached it with an open mind and seized the opportunity of the rule changes to go in many different directions, bucking the trends of recent years.”

Ferrari also took an interesting approach to the layout of its front suspension. Though not opting to head down the pullrod actuation route (one it has used before), the F1-75 features an interesting layout whereby the upper wishbone element and the tie rod are notably separated from each other, rather than tucked together in close proximity as has been the trend in recent years. The reasoning for this approach is unclear, though it likely relates to both aerodynamics and the mechanical packaging of the wishbone and tie rod with the suspension upright, as in plan view, the former has a considerable chord length.

[/accordion]

[/accordions]

[accordions]

[accordion title=”Ferrari engineering management comment” load=”hide”]

Mattia Binotto

Team principal and managing director

“The F1-75 is the expression of the talent, commitment and passion of each and every one of us. It is the end result of the work of a team that, like never before, has tackled the task with a new spirit and approach, pushing to the maximum in terms of innovation of every component, every detail, every solution. Striving to be innovative gave us an incredible boost in our daily work, on the way to producing this car. I am proud of the work that has gone into designing the F1-75. We know that expectations are high and we are ready to go up against our opponents. That’s the best part of this challenge and it’s what makes our work so fascinating. I would like the F1-75 to be the car that allows our fans to once again be proud of Ferrari. Our goal is to reignite the Prancing Horse legend and we can only do that by winning again. That will require a fast car and two great drivers, and we have them.”

Laurent Mekies

Racing director – head of track area

“Our race team is gearing up for the longest season ever and possibly for one of the most surprising seasons of the last decade. Different regulations, different cars, 23 races. It’s going to be an incredible challenge for all of us. Last year we had a good scrap for third place in the Constructors Championship and, as a team, we made significant progress. The coming season might hold some surprises. At the first race in Bahrain, there could be very little difference in performance terms between the teams, but then over the course of the year, we could see some teams and drivers make great progress. We will definitely have to manage our energy well, in order to stay fully focused all year long. We can count on our fantastic team spirit and our desire to test ourselves against the strongest opponents. In our favor, we have the incredible talent and dedication of Charles and Carlos, who have worked hard all winter with the engineers to develop the car in the right direction.”

Enrico Cardile

Head of chassis area

“The rule changes in 2022 are undoubtedly the most radical of the last 40 years. As a team we adopted a systemic and integrated approach to the challenge, defining clear priorities among the many objectives, often at odds with each other. In tandem with the car development, we improved our simulation tools to bring light into the dark corners that existed in the past. Aerodynamics was definitely our number one priority. We approached it with an open mind and seized the opportunity of the rule changes to go in many different directions, bucking the trends of recent years. This open-mindedness has extended to the development of the suspension: the new rules have imposed a general rethink, with the aim of giving us the flexibility to manage a brand-new car concept and tires with different properties from those used up until now. In short, so many variables came into play, making it a challenging and exciting exercise.”

Enrico Gualtieri

Head of power unit area

“It has been an intense and exciting challenge. All components have been re-evaluated: some have been optimized while others were decidedly innovative. We started from the main concept of seeking the utmost efficiency in the energy transformation process, from the chemical one in terms of combustion to the mechanical one, to the crankshaft. Everything else has been designed with this goal in mind. Working in an equally practical way, we also defined a power unit layout that best meets the needs of our colleagues on the chassis side, in view of the new technical regulations. We have worked with passion, determination and team spirit, aware of the responsibility of honoring not only our team goals but also the spirit of the entire company, which is celebrating its 75th anniversary this year.”

.[/accordion]

[/accordions]

[accordions]

[accordion title=”Key suppliers” load=”hide”]

Fuel and lubricant: Shell

Coolers: TBC

Safety equipment: TBC

HPC systems: TBC

Metrology: TBC

Simulation: TBC

Machine tools: TBC

[/accordion]

[/accordions]

McLaren MCL36

CEO: Zak Brown

Team principal: Andreas Seidl

Technical director: James Key

Executive director – racing: Andrea Stella

Director of aerodynamics: Tony Salter

Power unit supplier: Mercedes AMG HPP

[accordions]

[accordion title=”MCL36 in detail” load=”hide”]

McLaren was one of the first teams to unveil its 2022 challenger, with the MCL36 taking a unique design direction compared with the rest of the field with its use of pullrod rather than pushrod front suspension (which the team last used in 2013).

Technical director James Key commented, “With a blank sheet of paper, the team here at McLaren have been working hard to establish a competitive platform for this and future seasons. However, we know we’ve only just begun to unlock performance from this regulation set, and that one of the key features of the 2022 season will be the intense development war as teams assess each other’s designs and innovate new ways of generating downforce through ground effect.

“You have to – from a conceptual point of view – meld all of the current knowledge and expertise you have, into something that allows you to join the new tire characteristics to the suspension characteristics. A lot of it was theoretical and I suppose very conceptual for a long time.” Highlighting the scale of the changes this year, he concluded, “It’s my 25th season now and I haven’t seen change of this magnitude before; it has always been variations on a theme.”

[/accordion]

[/accordions]

[accordions]

[accordion title=”Key suppliers” load=”hide”]

Fuel and lubricant: Petronas

Coolers: TBC

Safety equipment: TBC

HPC systems: TBC

Metrology: TBC

Simulation: TBC

Machine tools: TBC

[/accordion]

[/accordions]

Aston Martin AMR22

Team principal: Mike Krack

CTO: Andy Green

Technical director: Dan Fallows

Engineering director: Luca Furbatto

Performance director: Tom McCullough

Power unit supplier: Mercedes AMG HPP

[accordions]

[accordion title=”AMR22 in detail” load=”hide”]

“Really, we are throwing away everything we’ve previously done and starting again,” explained Aston Martin chief technical officer, Andrew Green. “It’s been one of the steepest development curves that we’ve ever experienced – we’ve seen a 50% increase in performance in a matter of months, which is unprecedented. The AMR22 will evolve dramatically over the coming months as we run the cars for real and begin to understand the challenges involved.”

One notable shift for Aston Martin in 2022 is the team’s decision to use the entire Mercedes rear end, consisting on transmission, hydraulics and suspension, in addition to the power unit. This marks a departure from its previous approach of only using the Mercedes transmission, however, rear suspension design was an area of constant woe for the team, relating to some of its issues with highly condition dependent performance in previous years. According to Green, by opting to use the entire Mercedes rear end, it wouldn’t be ‘fighting’ to get the different elements working in harmony. The team did have an option to use the Mercedes front suspension as well, however, Green noted that waiting for Mercedes to finalize its design would have delayed work on the AMR02.

[/accordion]

[/accordions]

[accordions]

[accordion title=”Key suppliers” load=”hide”]

Fuel and lubricant: TBC

Coolers: TBC

Safety equipment: TBC

HPC systems: TBC

Metrology: TBC

Simulation: TBC

Machine tools: TBC

[/accordion]

[/accordions]

Alpine A552

CEO: Laurent Rossi

Racing director: Davide Brivio

Chief Technical Officer: Pat Fry

Technical Director: Matt Harman

Power unit supplier: Renault Sport

[accordions]

[accordion title=”A552 in detail” load=”hide”]

Beyond the 2022-driven changes, the biggest shift for Renault appears to be a shift to a split turbo/MGU-H setup for the RA22 designated power unit, following the lead that gave Mercedes such a decisive advantage at the start of the hybrid era in 2014. It would seem that beyond the benefits this architecture gives in terms of turbo compressor efficiency (it is possible to package a large compressor stage at the front of the engine), it also provides greater installation flexibility within the constraints of the new aero rules.

As team technical director Matt Harman explained. “At the very beginning of these regulations, we actually started with the power unit, mainly because it does set some of the key areas of the car dynamically, we did a full review of this area of the car. And we decided to change the architecture of that power unit extensively in all areas, including the internal combustion engine, the ERS, the turbo, and its positioning in the car. And that has given us some real gains in terms of our ability to express ourselves aerodynamically and achieve that ultimate laptime of the car.”

Harman admitted that the new regulations do place greater constraints on design freedom in many areas. However, he highlighted that this has driven the team to look at different ways of exploiting the performance potential within the rules. “We can already see that there are lots of areas to express ourselves within these regulations and use different areas of the car for different purposes than maybe we have done before. There are some areas of the car that are very, very different in terms of for example, their aerodynamic content, but then we’re finding other ways of dealing with those problems in other areas.”

[/accordion]

[/accordions]

[accordions]

[accordion title=”Q&A with Pat Fry, Alpine CTO” load=”hide”]

Q&A

How big are the rule changes ahead of the 2022 FIA Formula 1 World Championship?

“Quite simply, it’s a massive overhaul of the technical regulations for this year, which Formula 1 have been working on for five years or more now. I’ve seen a number of big rule changes in my Formula 1 career and this one is certainly up there in terms of its complexity and how restrictive the regulations are. When I first started in Formula 1 the rule book was relatively short and now it’s very extensive! The main concept of the change is to make overtaking easier and allow cars to run closer together, though, the complexity of the rules does heavily restrict what we can do aerodynamically. It’s going to be interesting to see the 10 different versions of the cars as each team brings their own interpretation to the track. Of course, there is always an opportunity to get these things right, or wrong, so it will be intriguing to see what our rivals have come up with.”

How has the team approached these rule changes in designing and developing the A522?

“With any set of rules, it starts with a clean sheet of paper. Our job is to dig into the wording of what each rule means and then see how we can exploit that within what is legal. The more people you have, the more ideas you can generate and the more ground you can cover. Rule changes are always exciting from a design point of view, but you have to remain sensible and realistic. Performance in Formula 1 comes down to three things: the people, the tools they have to work with and the methodologies. We know this set of rules are quite restrictive. We’ve done the best we can and everyone at the team has done a great job. We’ll keep improving the aforementioned three core pillars and the aim is to keep moving forwards.”

What have been the main challenges in preparation for this season?

“In terms of the car, the key area for this year for every team is getting the most from the floor as it needs to work very close to the ground and, at the same time, you need to get the cleanest possible airflow to the rear of the car. There’s also been a huge amount of work at Viry to produce a completely new power unit for this year, before its specification gets homologated through to the end of 2025. In addition, close collaboration between Viry and Enstone on packaging the power unit has allowed us some extra freedom in shaping the rest of the car and better exploiting the latest technical regulations. Keeping the car to the weight limit is always a challenge, made especially difficult this year with the large increase in the chassis load tests for safety, which are, of course, for very good reason. There’s also the financial regulations and the cost cap to contend with and that presents a number of ideas and strategies for car development, which we’re looking to capitalise on.”

How similar will the 2022 Formula 1 cars be to one another?

“I strongly expect there to be many differences between the cars, especially at first when we see for the very first time how we’ve all interpreted the rule book. Some parts are fairly set such as the rear wing and the front wing. I’m sure there will be some interesting concepts that we’ll see from other teams, which we’ll assess back at base after the tests and, equally, that will work vice versa. The intrigue is all part of the excitement when you roll out of the garage for the first time at testing. Of course, we’re all looking forward to seeing the A522 on track and seeing all the hard work at Enstone and Viry over the last couple of years come to fruition.”

[/accordion]

[/accordions]

[accordions]

[accordion title=”Key suppliers” load=”hide”]

Fuel and lubricant: TBC

Coolers: TBC

Safety equipment: TBC

HPC systems: TBC

Metrology: TBC

Simulation: TBC

Machine tools: TBC

[/accordion]

[/accordions]

AlphaTauri AT-03

Team principal: Franz Tost

Technical director: Jody Egginton

Head of aerodynamics: David Snodgrass

Sporting director: Marco Perrone

Power unit supplier: Red Bull (Honda)

[accordions]

[accordion title=”AT 03 in detail” load=”hide”]

Red Bull’s sister team from Faenza once again shares many of its major components with the senior team. However, whereas previously it used year-old kit, revisions to the rules mean Red Bull must supply its current parts, which include the transmission, rear suspension, hydraulics and, of course, power unit.

According to technical director Jody Egginton, the development battle in 2022 will be fierce: “It’s a clean sheet of paper for 2022, which provides potential rewards but also carries risk. The rate at which the car is being developed is a key metric, but an important question is, how far are we down the ‘development’ road relative to the competition? You don’t really get to know that until the first race of the season, when the gloves come off.”

Despite fears that the new rules would force teams toward the same concepts, Egginton feels there is still plenty of scope for design freedom. “With the change to the aero regulations being extensive, there is clearly a lot of scope to experiment with new ideas and new aero concepts, but at the same time the new regulations also provide an increased risk of going down the wrong development path,” he explained.

“I am quite sure there is plenty of scope for teams to come up with innovative aero solutions. But at the same time, I expect that the hidden details of aero development will be a significant contributor to what teams are able to achieve from the aero regulations. I’m pretty confident people are going to turn up at the first race with an interesting range of interpretations of the regulations and this will provoke discussion and investigation of possible development directions for all the teams’ in-season development plans.”

In addition to the all-new bodywork concept, the 18in wheels were a major consideration, said Egginton. “The influence of the wheel and tire on aero behavior is quite large. I expect the new tire-wheel package, as well as the brake ducts and the many aero surfaces and flow structures, which are influenced by and interact with the corners of the car, to continue to be an area where we can add performance as we develop our package. In terms of the tire itself, we were able to try them last year using our ‘mule’ car, so we have data and a good read on a number of the basic tire parameters.”

[/accordion]

[/accordions]

[accordions]

[accordion title=”Key suppliers” load=”hide”]

Fuel and lubricant: TBC

Coolers: TBC

Safety equipment: TBC

HPC systems: TBC

Metrology: TBC

Simulation: TBC

Machine tools: TBC

[/accordion]

[/accordions]

Williams FW44

Team principal: Jost Capito

Technical director: FX Demaison

Head of aerodynamics: David Wheater

Sporting director: Sven Smeets

Powerunit supplier: Mercedes AMG HPP

[accordions]

[accordion title=”FW44 in detail” load=”hide”]To follow [/accordion]

[/accordions]

[accordions]

[accordion title=”Key suppliers” load=”hide”]

Fuel and lubricant: TBC

Coolers: TBC

Safety equipment: TBC

HPC systems: TBC

Metrology: TBC

Simulation: TBC

Machine tools: TBC

[/accordion]

[/accordions]

Alfa Romeo C42

Team principal: Frédéric Vasseur

Technical director: Jan Monchaux

Head of aerodynamics: Alessandro Cinelli

Powerunit supplier: Ferrari

[accordions]

[accordion title=”C42 in detail” load=”hide”]To follow [/accordion]

[/accordions]

[accordions]

[accordion title=”Key suppliers” load=”hide”]

Fuel and lubricant: TBC

Coolers: TBC

Safety equipment: TBC

HPC systems: TBC

Metrology: TBC

Simulation: TBC

Machine tools: TBC

[/accordion]

[/accordions]

Back to car menu

Haas VF-22

Team principal: Guenther Steiner

Technical director: Simone Resta

Head of aerodynamics: Panayiotis “Ben” Agathangelou

Powerunit supplier: Ferrari

[accordions]

[accordion title=”VF-22 in detail” load=”hide”]

Simone Resta: “There were two main project challenges with this car. The new requirements of the chassis construction were one. With FIA Regulations, the 2022 monocoque has been heavily modified for safety reasons. The strength requirements are a lot tougher with some areas being more than 150% stronger. This required a significant amount of reinforcement with respect to 2021, with a relevant impact on weight. Conversely, the weight of the car is a challenge by other factors as well. In terms of creating a new car, it’s probably the most complex in the last 20 years.

“It has also been a challenge at times when creating such a radically different car when internally we’re also creating new processes and structures as the team has been created. It’s hard to appreciate starting with an entirely new department and being tasked to lead such a project.

“Although it has been a challenge, I can’t stress enough how proud I am of the team we have built over the past year. With new team members, many from Ferrari, and working very closely with Dallara, we’ve now got a fully fledged design office in Maranello. If we look back a year ago to where we are now, I think there has been a dramatic step forward and if we could take the staff we have now and go back to this time last year, it would’ve been fantastic to start the project with them.

“It’s important to highlight that we are still in the early stages of our development and transition, we will still grow a lot this year and finesse areas and skill sets. I expect that we’ll see the best deployment from this team in one year after developing the car and in general just more time working with each other.”

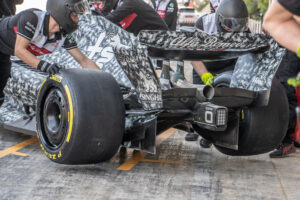

“The biggest change is the aerodynamics, and from that perspective it’s a complete revolution because the regulations are so different. The brakes and the brake ducts are a big change as well. Not a revolution per se but very different compared to previous years.

“In terms of the car itself – other than the steering wheel, pedals and extinguisher – there are no carryovers. Everything must be changed essentially. In certain aspects, freedom is limited compared to previous years, but the devil is in the detail, so I suspect that we will see a vast difference in performance across all cars.”

[/accordion]

[/accordions]

https://twitter.com/i/status/1495682741177827330

[accordions]

[accordion title=”Key suppliers” load=”hide”]

Fuel and lubricant: Mobil 1

Coolers: PWR

Safety equipment: Sabelt

HPC systems: Hewlett Packard

Metrology: Hexagon

Simulation: Hexagon

Machine tools: DMG Mori

[/accordion]

[/accordions]