Racing in America developed in different ways across the country, from early purpose-built tracks in the Midwest, the hard sands of East Coast beaches, and the dry lakebeds of California.

There is another, unique racing venue on the vast expanse of salt, east of the town of Wendover, Utah: the Bonneville Salt Flats. For more than 100 years, Bonneville has created a competitive spirit that has attracted racers from the likes of Mickey Thompson, Bobby Issac (of NASCAR fame), and Valerie Thompson (the fastest female motorcycle racer), and has challenged racers to test the limits of speed.

This is an equal opportunity environment – you don’t need a giant budget or thousands of horsepower to challenge the Salt. Engine classes run from 30 cubic Inches (490cc) to 501 cubic Inches (8 liters), in 12 different engine size classes. Some speed records are still less than 100mph, so with creativity, smart use of budget, and a lot of courage, anyone has a shot at the record books.

Burton Brown of Victory Motorsports heads a small team from Dale, Wisconsin, that has worked to set records in speed with their Streamliner. His crew is a combination of skilled craftsmen and weekend warriors that dedicate their time to a form of racing that requires a strong team approach.

The progress of NACA duct integration for Land Speed attempt

“Getting into the 200MPH club was always a general goal. My dad and I always talked about someday getting a ‘red hat’. I promised him I’d get him one someday, so that had always been something I intended to do. We knew from the start our Streamliner would be capable of running 300mph, so we had a few goals during Speed Week 2017 we hoped to accomplish. The first one was to break the long-standing F/DS record @199.015mph from 1979. Additionally, we hoped to not only break the record, but go 250+MPH and obtain an AA License, which would have allowed us to take a shot of going 300mph (you need different licenses to go higher speeds),” explains Burton. “We named this venture ‘The Junkyard 300’ as the engine we were using came directly out of the salvage yard in January without disassembly. We then fabricated a header, added the Borg Warner S300Turbo and an OM606 Fuel injection pump by Dieselmeken AB Sweden as the only major changes. We don’t have the budget that some of the teams have, so there are many parts on the car that we obtained very cheaply (some were laying around in the shop, on E-bay, Racing Junk, and we even found a few at rummage sales). Long time Bonneville racer Jack Costella once said, ‘Go as fast as you can for the least amount of money.’ We try to cut costs where we can, so we can use the money we save for the trip back and forth from the Salt. That is part of the fun for me.”

The new Windform SP intake duct

Another key component for Victory Motorsports’ attempt to meet their goals would be a new intake duct designed by David Woodruff from Design Dreams LLC for the Streamliner. Early in 2016, Burton had CRP USA produce velocity stacks for his other record-setter, his 240Z, which currently holds records in the F/GT classes.

The new engine for the 240Z (E-GT) was not going to be ready, so the team began concentrating all efforts on the Streamliner. With less than a week to go before the deadline to load the car onto the trailer for the 1,600-mile, 32-hour drive, the team realized that the complex design produced by David Woodruff was not going to be complete through use of a standard mold, and the combination of high frequency vibration, intense sun, and high temperature started narrowing the options.

Burton was running out of time.

“Stewart Davis from CRP USA had called to check on the progress of the Z engine and I had to tell him we wouldn’t make it with the 240Z and that we had switched our complete focus towards the Streamliner,” Burton states. “I explained we were struggling with the duct and asked if Stewart and his team could help us with that challenge. So, we talked more about the possibility of CRP making the ‘Naca-Scoop’. Without hesitation, Stewart asked for the model and CRP USA produced an absolutely perfect piece.”

The part – at nearly 28 inches long, with a complex interior design – would be an interesting challenge. Being familiar with NACA ducts, the CRP USA team knew the work involved to make the surfaces smooth, required for optimum flow.

“The design has some extra complexity to help the air flow at the base of the Turbo inlet, and it looked a bit daunting,” explains Stewart Davis, who reviewed the part. “We had to build it in 3 sections, but our finishing team was able to apply their knowledge and skill to give an expert polish.”

CRP USA received the final model on July 26th. When completed, the part was sent to Victory Motorsports, and arrived on August 1st.

Upon arrival, the fitment was confirmed in the engine bay, and all appeared to be going smoothly; however, a complication arose when the newly painted fairing arrived. The scan data used by David Woodruff had been developed using the exterior surface of the fairing, and there was a miscommunication with the designer.

“The fit to the engine was great but the curvature to the body from the scans must have been off a little and this created some challenges getting it to fit to the body.” With the clock ticking, the team loaded everything into the truck, and headed for Utah.

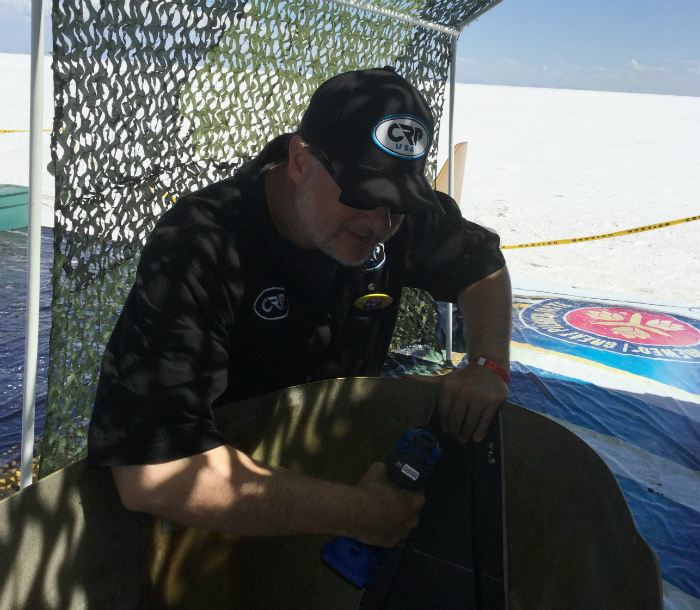

“Burton had invited me to come and see the Streamliner. When I arrived on Friday morning, we reviewed the fitment issues,” Stewart continues. “Attempting to force the part was not working. CRP’s Windform SP is a very tough material, so the decision was to fracture a section of the part to allow a little give, so it would match the curve of the fairing, and then reinforce it by riveting an aluminum backing plate.” Utilizing the onsite tools, the team worked Saturday and Sunday to prepare – both for the first runs, and to modify and refit the NACA duct.

On Sunday, the Streamliner passed tech, and the team prepared for a Monday morning run. The opening speed week passes on Saturday had yielded two runs above 400 mph, so Burton knew that the potential for breaking the record in their class was a possibility. Conditions were good Sunday, but the track had started to get rough in some areas. Burton elaborates that the track was a lot rougher than ever experienced at Bonneville.

“The Mining has taken its toll on the surface,” states Burton. “The first pass, I drove through lots of rough stuff and found about the 3.5-mile mark that the track got smoother. The Streamliner withstood some damage to the fiberglass due to the roughness of the salt/silt surface and with how rough parts of the track were, we ended up doing a little salt plowing. Our exit speed at mile 6 was 234 MPH.“

The radio announced that the team had qualified for the record, and the car was placed in impound where they have up to four hours to inspect the car for safety for the follow-up run. The team was back at work; cleaning, tuning, and examining for any damage. To gain the record, each team must complete two runs, with the average used to calculate the new record. The backup run to establish the two-pass average was to be Tuesday morning – record 2nd runs always start at 7am, prior to any other cars making passes.

On Tuesday morning, the team celebrated the radio announcer’s call of a new class record. The track was on a new course that had been moved approximately 150 feet to the south, as the end of the day Monday exposed some damage to the existing course. With the engine making plenty of power, it was the rough surface making it a challenge to get the power to the Salt. “I was pretty sure we got the record but needed verification from the crew. With the traction issues and exit speed of 234 MPH, we know there is a lot more in this car and setup, “Burton and the team feel 300mph continues to be a possibility, if the track conditions were improved.

“The Windform SP part performed extremely well, and held up to all of the abuse, even being heavily modified while on the salt flats, with limited tools and time,” added Burton. “I am still completely amazed at the strength of the Windform SP. It gave us no issues withstanding the speed and the rough track and vibrations. It is a very light, strong material that can also take the extreme heat generated in the very tightly-fitted body. A few years ago, I wouldn’t have dreamed of having something like this on the Streamliner.”

Stewart Davis stated, “It was great to be a part of the team’s record-setting run, and we congratulate Burton and his team on the record. Now we are all looking forward to seeing more with both the Streamliner and 240Z when the new engine is completed. We are fortunate to work with teams that are dedicated to their sport, and the Victory Motorsports Team is a great example of the hard work and determination it takes to be successful.”