Mitsubishi Chemical Corporation has developed a new cyanate ester carbon-fiber prepreg that provides both high heat resistance and excellent strength.

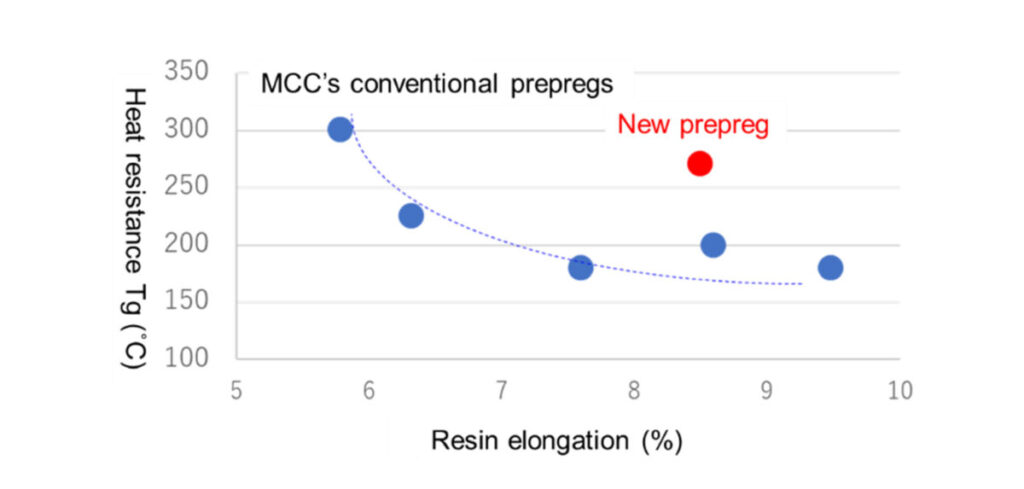

Generally speaking, there is trade-off with conventional CFRPs between heat resistance on one side and strength and processability on the other. Component manufacturers are thus constantly competing to develop items that deliver an optimal balance of these key factors.

MCC states that its latest prepreg achieves excellent results on both sides of this traditional trade-off by using a cyanate ester-based resin developed by combining raw materials and its proprietary catalyst technologies.

The prepreg is claimed to not only withstand temperatures of up to 250˚C but also provides the flexibility and toughness of more traditional CFRP materials. The prepreg can also be cured in the same molds as traditional epoxy resin-based CFRP, giving it better storage stability than conventional cyanate-ester resins and delivering excellent processability for customer applications.

MCC says that the prepreg is already in use in some racing engine applications, and it is aiming to expand the new product’s marketing scope from applications in the automotive sector to uses in other industrial applications.