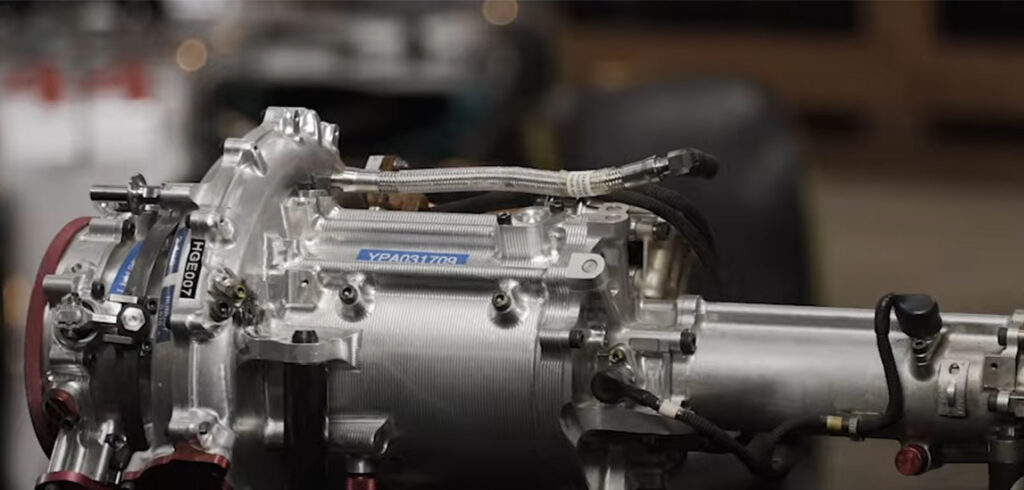

In a recent consumer-targeted video highlighting the technology of its Formula 1 powertrain, Mercedes revealed the first images of its Formula 1 MGU-H system. Though the company has given details of its power units in the past, this is the first time it has shown the entire MGU-H in public.

When the hybrid regulations were first introduced back in 2014, it became apparent the German team had adopted a layout for its exhaust gas recovery system that positioned the compressor at the front of the IC engine and the turbine at the rear, with the MGU mounted in the vee. Both Ferrari and Renault opted to mount all of the turbocharger components at the rear. When it arrived in 2015, Honda took a similar approach to Mercedes.

There are a number of advantages to the Mercedes approach; not least, positioning the compressor at the front of the engine allows for a larger, more efficient unit to be used. However, one major hurdle Mercedes had to overcome was controlling vibrations and flex in the inherently long shaft, running at up to 125,000rpm, which had to run the length of the engine, connecting the compressor, MGU and turbine, which by regulation is required to be a single assembly. This was an area where Honda struggled with the early iterations of its power unit. Looking at the image of the MGU-H, it would appear that two position sensors are located along the shaft, presumably to monitor for such issues.

The compact size of the MGU-H is impressive, particularly given the conditions under which it operates and an output of around 100kW, coupled with a regulation service life of anything up to 5,000km (in 2015, one of Mercedes’ PU106B power units clocked up over 5,000km running in a Force India).

This is the first look at a component fitted to cars since 2014, which gives some indication of the tight wraps manufacturers have kept on what is, still, cutting-edge technology.