Brabham Automotive has revealed some of the steps it has taken to minimize weight on the BT62, its track use only sportscar. It explains that the most obvious weight saving measure is the use of lightweight materials in its design and construction.

Brabham says its designers adopted the first principle of design function – use the right material in the right application to maximize its function. It notes that this is counter to the philosophy to use a material, which is perhaps in vogue, but in an application which then requires additional reinforcement thus increases mass.

To this end, the BT62 uses a blend of components made from carbon fiber, carbon Kevlar (used for wheel housings) and chromoly steel. Interestingly, the company argues that its choice of chromoly, rather than carbon, was performance- rather than cost-based, claiming ‘unparalleled torsional stiffness’ for the chassis, while also saying a carbon tub would have added 65kg to the vehicle’s weight. While on the surface this may seem surprising, the car competes in GT3 spec, where regulations require a steel roll structure, even if a car with a carbon tub could pass crash tests without it. Thus, any carbon chassis would still need augmenting with a chromoly cage.

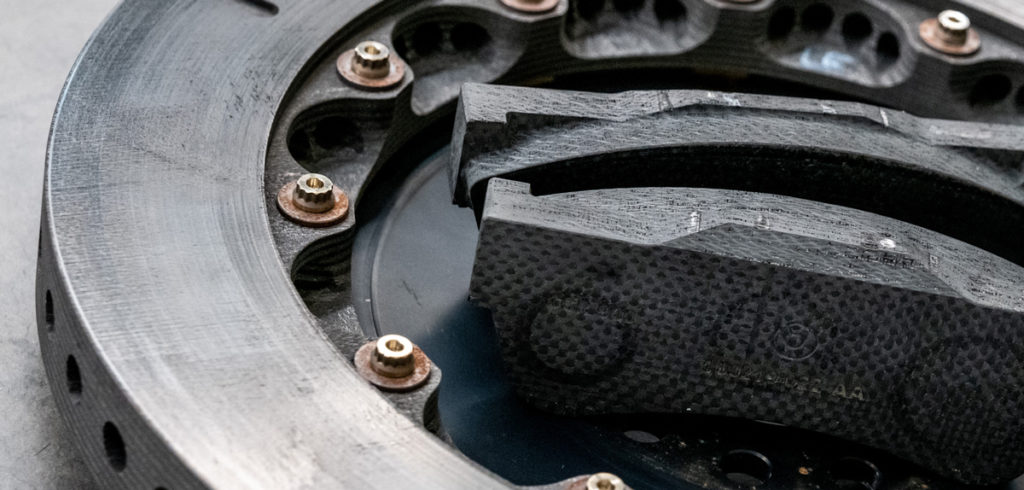

Brabham goes on to state that the use of carbon/carbon brakes reduced mass in each corner by 5kg compared with traditional iron brakes, and the weight of the Cosworth-developed, Ford-blocked engine has been reduced by 15kg compared with that of the base unit.

In addition, the BT62 has a static weight balance of 42:58, front to rear, which gives more weight over the driving wheels during take-off and acceleration. However, Brabham says the car’s aerodynamics create a 50:50 dynamic weight balance under braking and in cornering.