Multimatic has made its DSSV damper technology widely available to Formula SAE and Student teams. Developed as a collaboration between student engineering interns and Multimatic’s vehicle dynamics team, the new dampers leverage the system architecture and spool valve cartridges of the company’s GT and prototype-level race dampers.

As part of a pilot program run through 2020, three Canadian university teams and one in the UK each configured, assembled, dynoed and tuned a set of dampers to their own specifications and vehicle requirements, ahead of testing on their cars. With the pilot program proving a success, the company has now made the dampers generally available.

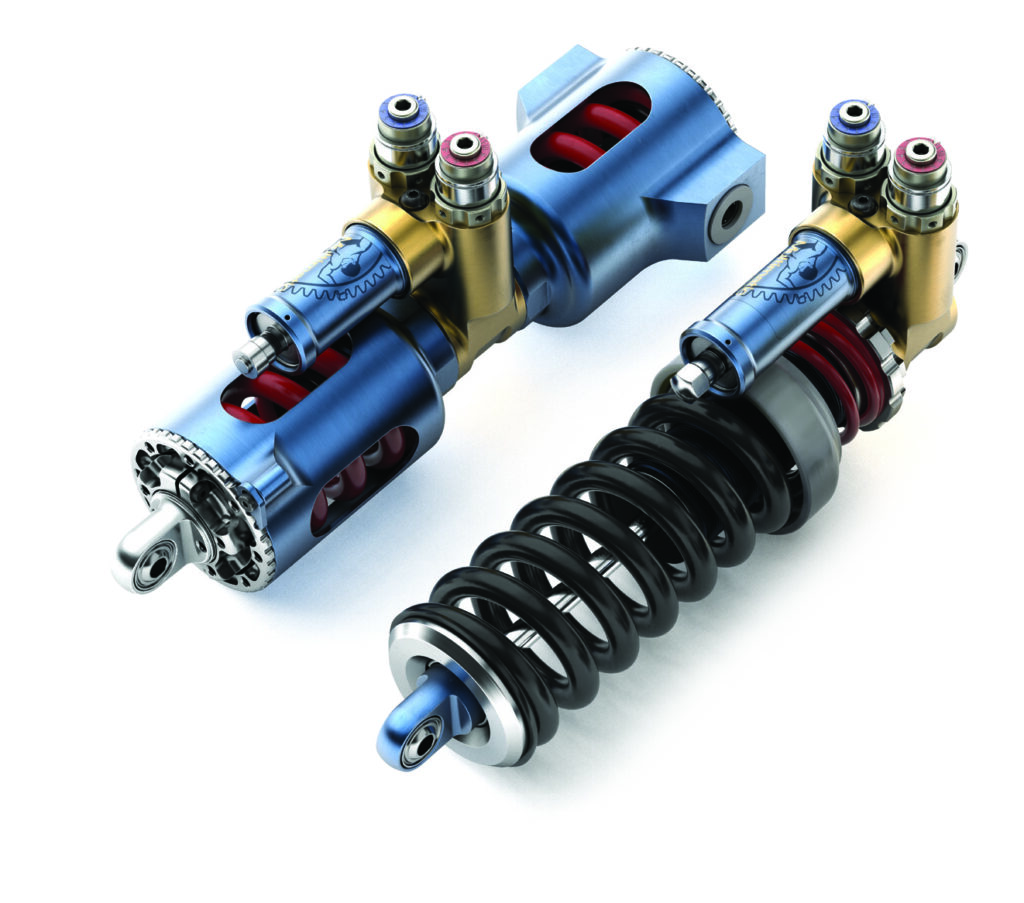

Dampers can be supplied for either conventional four-corner suspension setups, or systems with front and rear decoupled roll/heave. Key to the DSSV design is the use of spool valves to control oil flow within the damper, which Multimatic says provides excellent control and repeatability when it comes to damping characteristics, giving a tolerance claimed to be within a maximum of +/- 3% of total damping force from valve to valve.

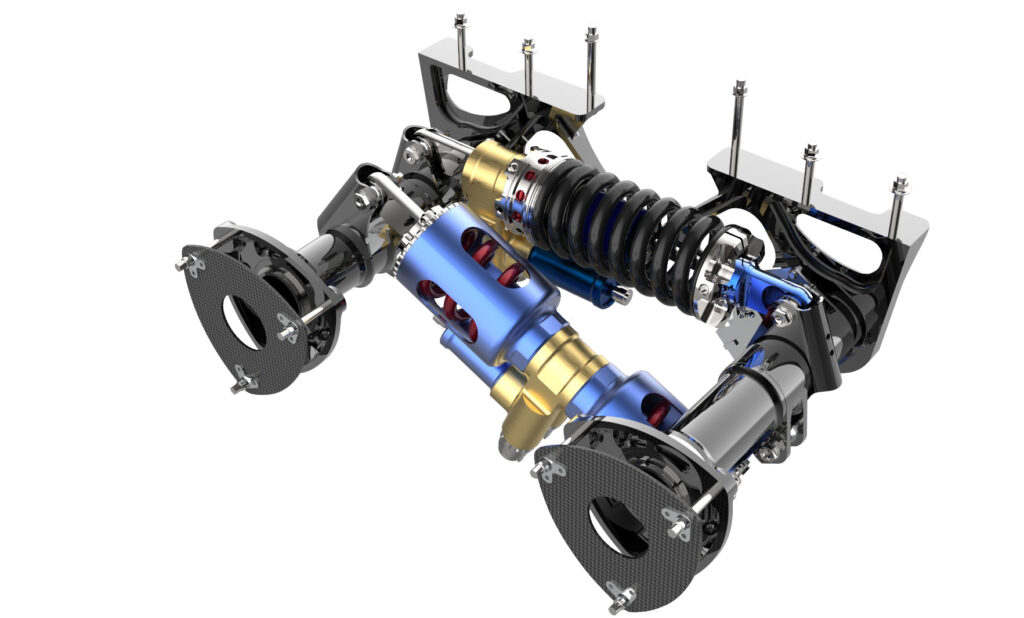

Multimatic also notes that this is the first time FS teams have been offered the option of purchasing a mode decoupled damper system, with separate heave and roll dampers. In a conventional independent suspension, springs and dampers are simultaneously actuated in all four modes, making independent control of each mode impossible. A mode-decoupled suspension enables discrete control of stiffness and damping for each chassis mode. Each can then be tuned individually.

For example, high spring rates help control chassis attitude while softer rates help maximize tire grip. A mode-decoupled suspension provides flexibility with regard to this compromise. Improved ride height control also reduces aerodynamic center of pressure migration, improving vehicle balance and high-speed stability.

For example, high spring rates help control chassis attitude while softer rates help maximize tire grip. A mode-decoupled suspension provides flexibility with regard to this compromise. Improved ride height control also reduces aerodynamic center of pressure migration, improving vehicle balance and high-speed stability.

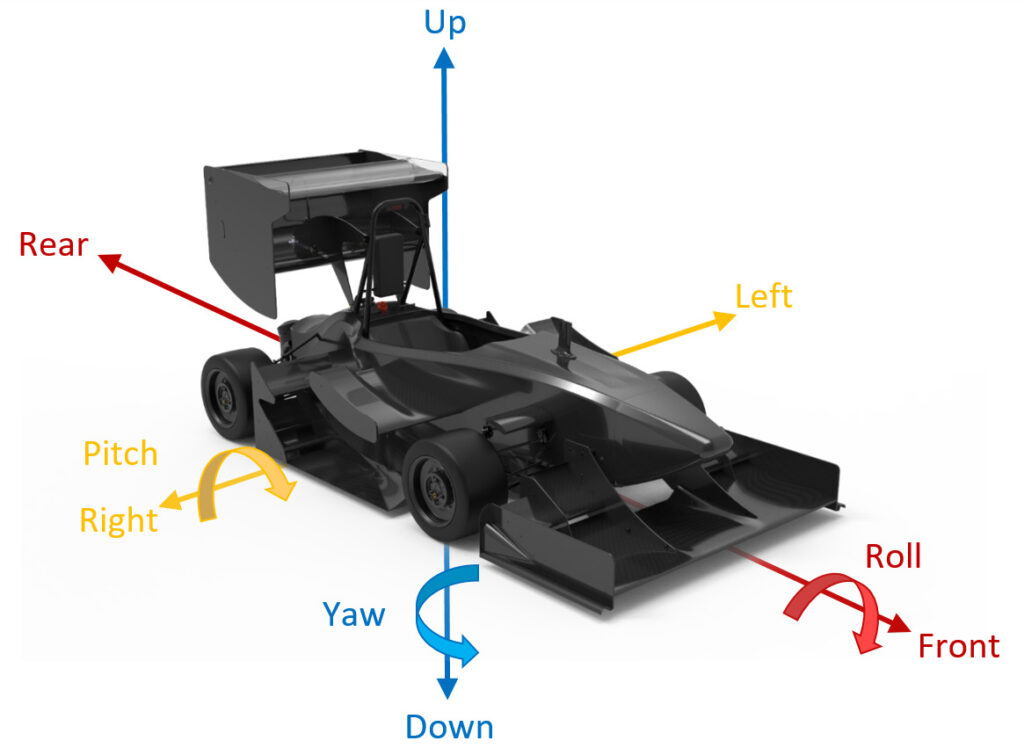

Other benefits include minimized contact patch load variation through independent modal damping, which helps improve overall grip. Greater control of lateral and longitudinal load transfer through all vehicle maneuvers also provides improved transient response and driveability.

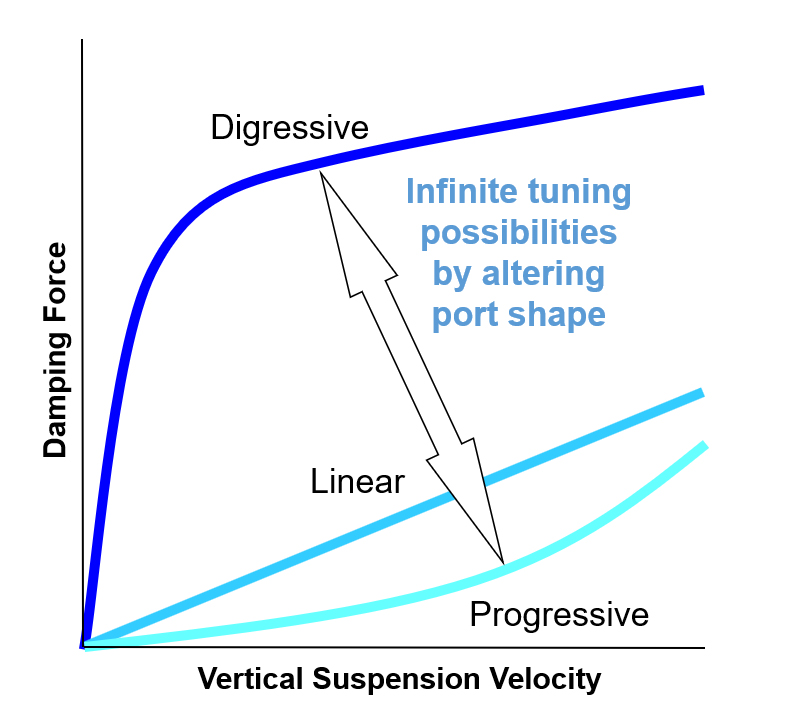

The damping curves can also be almost infinitely varied through changes in the geometry of the port windows on the spool valves, and the rate of the valve control spring, giving scope for linear, progressive and digressive damping curves.

The damping curves can also be almost infinitely varied through changes in the geometry of the port windows on the spool valves, and the rate of the valve control spring, giving scope for linear, progressive and digressive damping curves.

Multimatic has long been involved with Formula SAE and Formula Student through judging at events, team sponsorships, and the establishment of a vehicle dynamics award at the Canadian Formula SAE North competition. The company also recognizes the importance of exposing talented young engineers to innovative technologies and helping them develop and learn from hands-on experience.