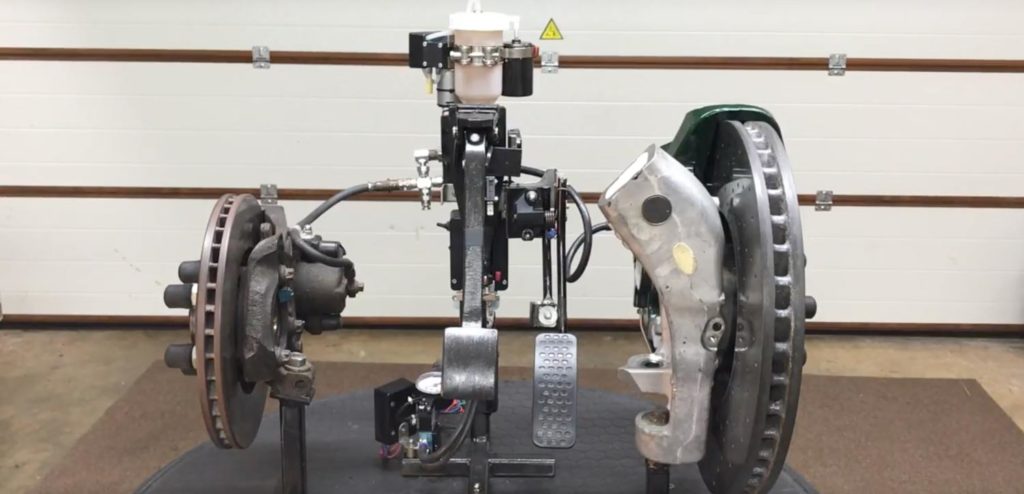

Brake design specialists AirBack has introduced a drag-free brake design that the company claims significantly improves braking efficiency. Designed as an add-on system, AirBack reduces the friction between brake pads and discs without compromising the performance of the brakes.

The technology, which operates as a retraction and pre-fill system, utilizes positive and negative pressure and vacuum to deliver a minute gap (depending on the actual brake caliper design) between the brake and the disc. This is achieved by applying negative pressure to the brake line during acceleration and then supplying positive pressure when applying the brake.

This design incorporates miniature compressors and Lee Product’s plug-in Lo-Lohm Latching three-port HDI Solenoid Valve, which combines the high flow capabilities of their Lo-Lohm HDI valve with the power savings of their Latching HDI valve.

This three-port Lo-Lohm latching design excels in applications like the AirBack brake system where high flow capacity, low power, miniature size and 100% reliability are critical.

After supplying a momentary voltage pulse (10ms minimum), the magnetically latched solenoid valve holds its flow state until follow-on momentary voltage pulse (with reverse polarity) is applied to switch its flow direction. Aside from the momentary pulse, no power is consumed while maintaining each flow state.

The AirBack system has been designed to be failsafe during power interruption or removal from mid-cycle, without compromising normal braking performance.

System settings can be optimized for reduced brake pedal travel (safer) or less non-braking drag (economy). During accelerator use, brake drag is removed by adding negative pressure to the MC. With the accelerator linked system, when the accelerator is released the compressor adds positive air pressure to the MC reservoir, pre-filling the fluid system ready for use.

When brake actuation occurs, the compressor switches off to ensure that the system does not affect any other brake control system during its use. The compressor otherwise continues to be operational because motorsport applications require continual use.

With the electronically controlled system, when the accelerator is released, a positive pulse of high pressure air is added for a few 10ths of a second from a small reservoir which causes the caliper pistons to return to their former position and be in firmer contact with their respective brake pad. This means that there are no piston gaps remaining and the brake pedal stroke is much reduced providing a faster acting, safer brake system.