Audi has detailed some of the steps taken to ensure that its 2022 Dakar racer, the RS Q e-tron, keeps both its occupants and drivetrain safe.

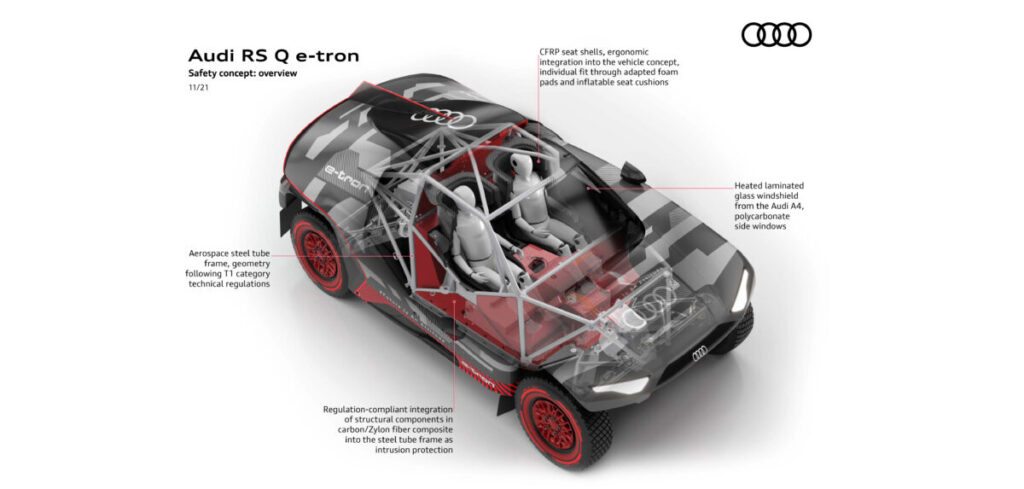

Starting with the basic roll cage and tube-frame chassis, the regulations stipulate that this structure must be made of metallic materials. Audi has opted for a heat-resistant, alloyed quenched and tempered Chromoly steel for this structure, and notes that it additionally protects the drivers with panels made of composite materials in the spaces between the frame. These components are made of carbon fiber-reinforced plastic (CFRP), in some cases supplemented by the tear-resistant Zylon, and prevent the penetration of sharp and pointed objects from outside.

Likewise, they protect the drivers and co-drivers from any problems with the high-voltage system. “The structural design of the frame incorporated methods and findings that we have honed over decades in many disciplines,” noted Axel Löffler, chief designer RS Q e-tron.

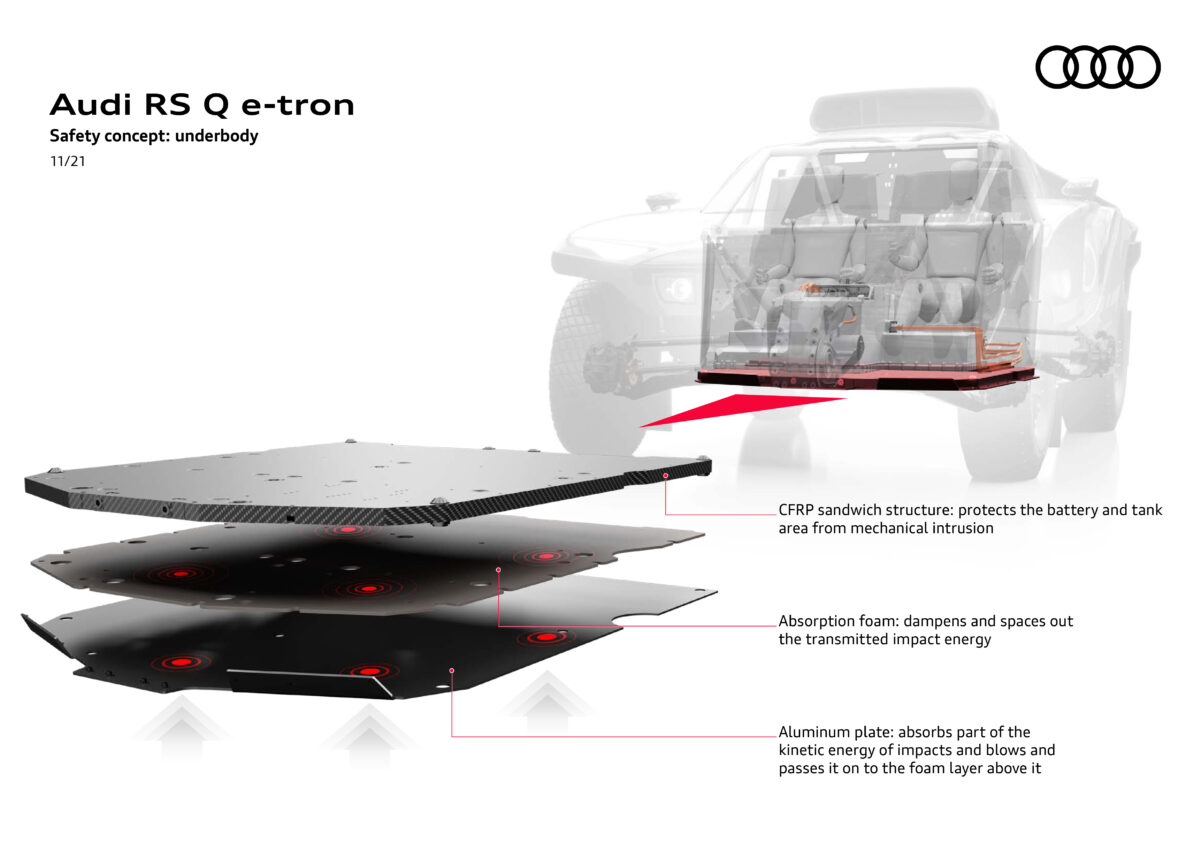

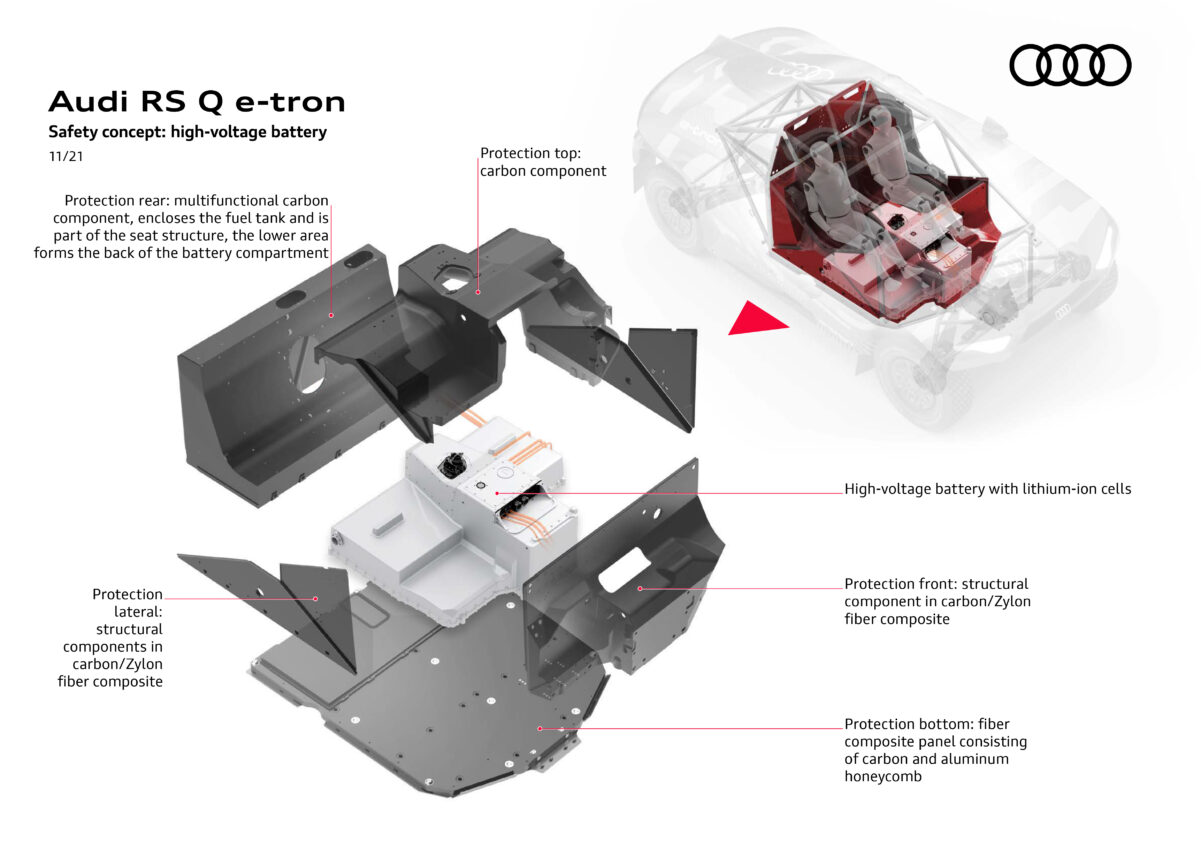

Meanwhile, the high-voltage system of the electric drive and the IC engine require multiple layers of protection. The encapsulation of the centrally located high-voltage battery comprises CFRP structures, some of which are reinforced by Zylon. The protection for the underside is particularly complex.

The underbody is the area most vulnerable to damage, thanks to heavy landings from jumps, stone impacts and the need to scale steep obstacles. Its lowest layer consists of an aluminum plate to resist abrasion by hard objects and partially absorb impact energy. A layer of energy-absorbing foam above soaks up impacts and distributes them to the composite sandwich structure above. This third structure protects the high-voltage battery and the gasoline tank for the IC engine.

The CFRP sandwich structure performs two main tasks: the absorption of the surface load, which is passed on from the aluminum plate via the foam; and the dissipation of energy by crushing when the surface load is exceeded. This controlled collapse thus protects the battery above. In the event of excessive damage, the assembly can be easily replaced during the evening service in the rally bivouac. In total, the underbody with its triple protection against impacts and intrusions is 54mm thick.

The CFRP sandwich structure performs two main tasks: the absorption of the surface load, which is passed on from the aluminum plate via the foam; and the dissipation of energy by crushing when the surface load is exceeded. This controlled collapse thus protects the battery above. In the event of excessive damage, the assembly can be easily replaced during the evening service in the rally bivouac. In total, the underbody with its triple protection against impacts and intrusions is 54mm thick.

“With these designs, we see a direct transfer of our knowledge from the circuit to cross-country rallying,” said Löffler. “And there are further parallels, for example in the loads for the chassis and underbody. Admittedly, the energies are higher off-road because of the long suspension travel, the duration of the load and the vehicle mass. But the g-forces measured are similar to those of Le Mans prototypes.”

Further measures complete Audi’s high-voltage protection concept. An ISO monitor, known from LMP and Formula E, detects dangerous fault currents. In the event of maximum kinetic loads, such as a collision, the system switches off automatically above a threshold value. Lights on the body and an acoustic signal tone serve as danger warnings to the outside world – for example after an accident. Insulation of the system against water during river crossings and an electrically insulating extinguishing agent in the onboard fire extinguishing system are also used. The entire team, including drivers and co-drivers, have also undergone high-voltage systems training, as have rescue teams from the rally organizer.